TIMELINE AND

UPDATES

(BELOW ARE MORE RECENT

UPDATES)

4/15/13 - It's been a month since the last post and I've been

doing quite a bit of work. One thing for sure...every corner

you turn on this thing comes with a new twist! Part of this is due

to the changes I've decided to make. Start one

thing....consider another...stop, research, buy parts, finish the

second and then go back where you left off. Then do it all

over again for the next step. It's crazy and I can't wait

until it all begins to fall together. Yes, it's still pretty

early and this is the point where hours and hours of reading,

research and parts ordering slows things down.

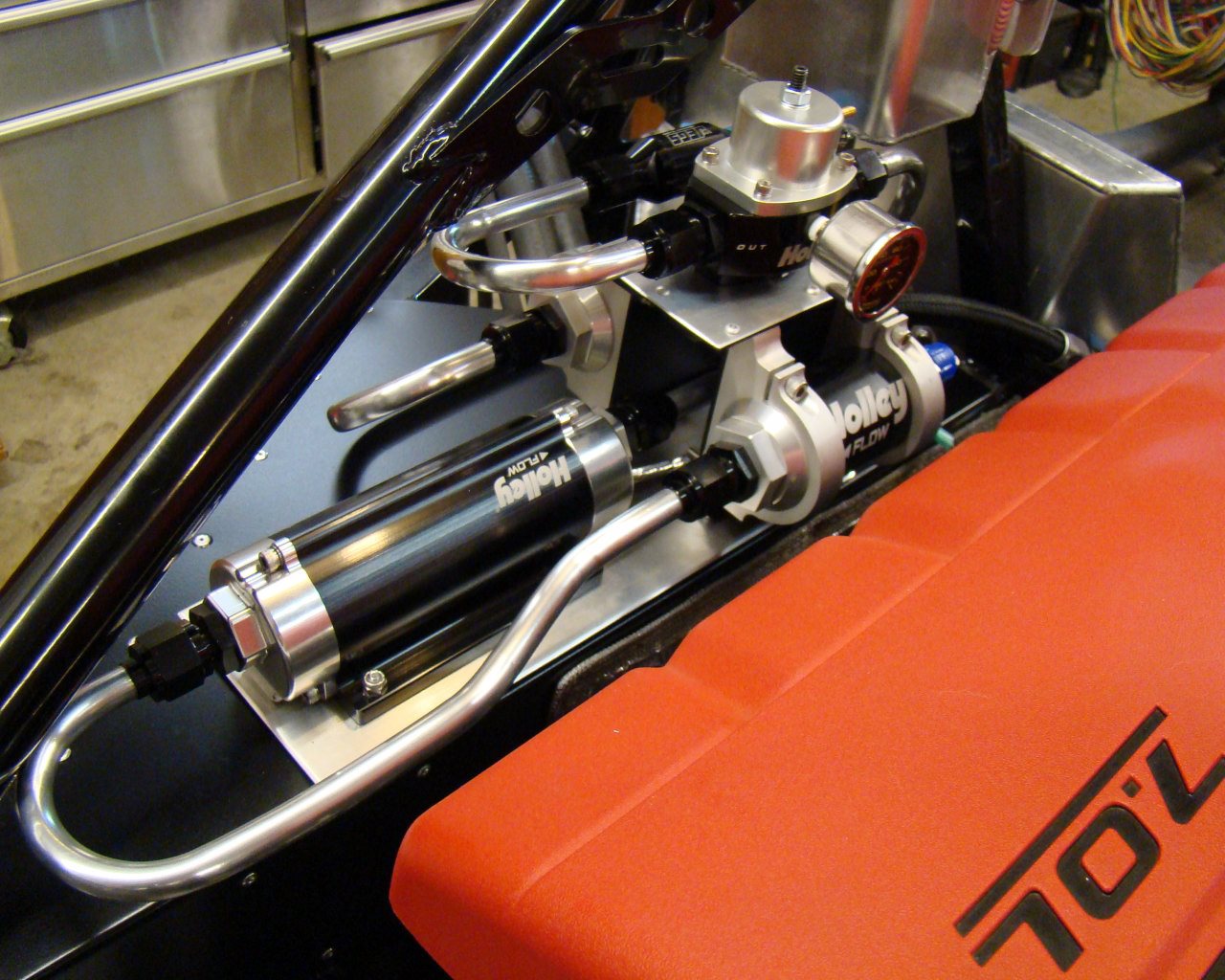

I've got the entire oil system, fuel system, race logic system

and standalone engine harness. I've also got the Cadillac

CTS-V alternator parts and AC compressor mount

and pulley. The engine

harness is completely redone (had to strip the new one

and reroute everything in order to get the wires headed in the

right direction.) It turned out pretty close to exactly what

I needed. The computer harness feeds directly from the right

side of the engine to the computer mounting area. The left

side of the harness (Gas pedal, Code reader connector and the

ignition wiring feed down the left side directly into the

tunnel.

I dropped the

engine in on Saturday without issue. The AC

lines will require slight lengthening before connecting

to the compressor. I went through the cooling/heater system

and purchased the constant flow valve from "My Race Shop" and plan

to plumb all that next. I mounted the Canton

tank on the left frame member just above and to the

right of the engine. I received the TIG welded aluminum tanks

(Quick Racing Products) and plumbing as well. So, long story

longer.....I've got what I need to actually get some work

done. Check the pages for updates.

3/11/13 - CANTON TANK AND HEATER BYPASS VALVE

INSTALL:

I decided to go with the Canton Expansion tank from Summit

racing and heater bypass valve setup from "Crash" at "My Race

Shop". The picture here shows the forward overflow tank (Not the

Canton Expansion tank near the engine)These were recommendations

and seem to be the hot tip for keeping the expansion tank at the

proper level near the engine and also having proper operation of

the heating system. Some guys use an overflow tank as

well. I decided to purchase a second Canton tank to be an

overflow reservoir up front. Its a simple overflow tank with

site gauge and a petcock drain. The photos in the cooling

section show how I mounted it after verifying it would fit with the

wiper motor mounted. I'm still waiting for components for the

engine oil and fuel system so I'm not quite at the point I want to

drop the engine in the chassis. Also, I've got the LS7

standalone wiring/ECU setup on the way and will be doing some

prewiring prior to engine installation. Once the window wiper motor

is ready to be installed, I'll probably modify the aluminum wiper

mount bracket to access the cap a little easier. When I do,

I'll beef up the wiper mount by picking up adjacent chassis or

firewall mount points with custom angles/sheet

metal.

The last few weeks

have been spent on some small things here and there and getting

caught up on the parts I need for the motor. I've purchased a

Cadillac CTS-V Alt mount, Aluminum Tanks, Peterson Oil system tank,

LS7 harness/ECU, fuel system plumbing etc in preparation for engine

installation.

LATEST - Updates for the day

below. Use above index for detailed photos of all sections of the

car.

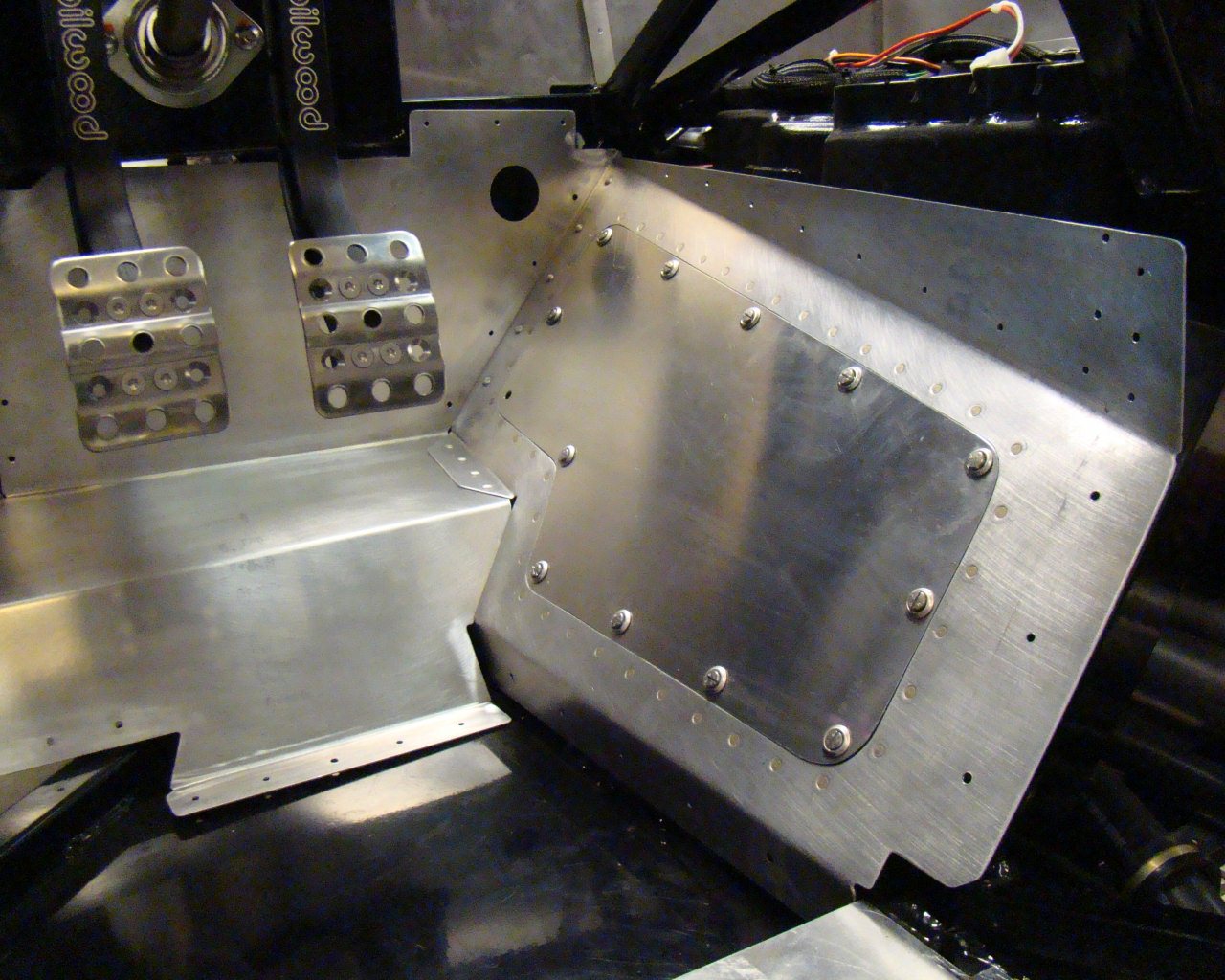

5/23/13 - Did

some additional work on the fuel system and floor panels in

anticipation of installing the fuel tanks. I re-configured

the fuel delivery system several times and ended up re-making hard

aluminum lines to route them near the canton expansion tank and to

get the entire assembly to fit on the aft left sheet metal

shelf. I've added many photos in the "Fuel" page to show the newer installation.

Also, I took a series of pictures aligning and drilling the floor

mount panels for the center tunnel, engine and fuel tanks.

They offer a pretty good reference for positioning and drilling the

holes. See the added ""Floor and Undercarriage" page to see the new

photos.

5/13/13 - Another

month has passed and I've added pictures in various sections of the

site. The LS7 "Harness" and "Fuel" pages have been updated

and I added a page for the Petersons dry sump tank mounting and

plumbing. Below are some pictures of the

latest.

5/27/13 - Fabricated oil lines for catch

can. Also fabricated PCV pickup from AN fittings - Drilled

and tapped -12 AN coupling for LS7 PCV lines that normally go to

dry sump tank. Fabricated Corvette fuel rail cover blank-off

plates and installed Factory Five logos and

lettering.

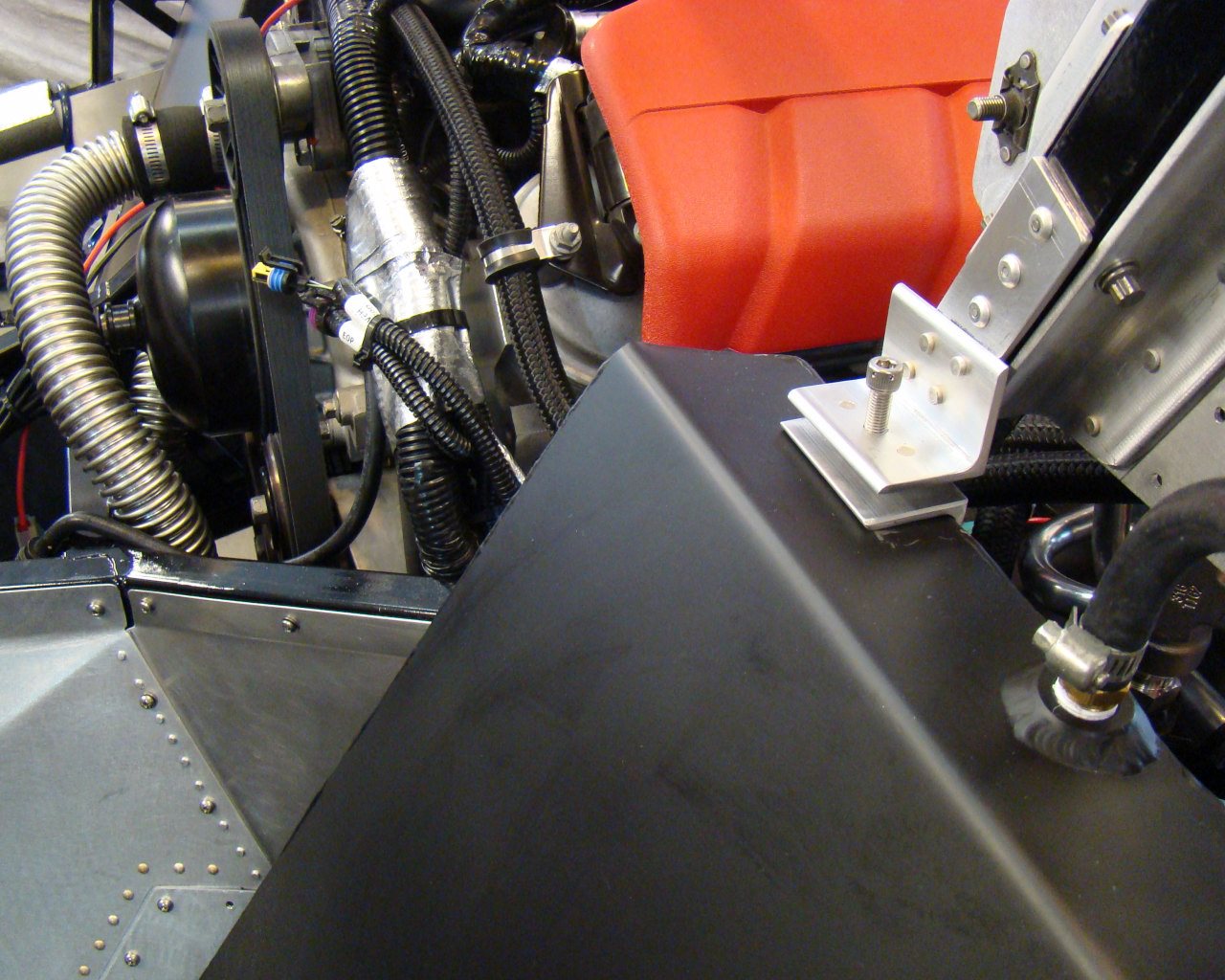

6/7/2013 - I worked a solid 10-12 hours Saturday

and Sunday on the tanks, fuel system and some odds and ends.

I decided to fabricate tank hold down brackets to help keep the

tanks from moving around. There's many different ways to keep

the tanks in place but I decided a few stops mounted to the frames

and a hold down bracket to clamp them in place would be better than

padding stuffed between the frame and sheet metal panels. I

also added a heat shield (Hand fabricated ) to keep the fuel system

cool. The system lines and filters are sitting pretty close

and above the headers. The shield helps absorb the heat and

will keep any leaks from dropping directly on the headers.. I

added appx 20 photos to the fuel

section.

7/22/2013 - Been working on the engine fuse box mount

installation. I fabricated a metal mount from several

channels and sheet aluminum so that it could be easily assembled in

place and removed for maintenance. The cats are directly

beneath the unit so I purchased 1/4" ceramic/stainless heat shield

wrap and stainless zip ties to cover the cats and keep the heat

down in this area.. Additionally, I will be installing a heat

shield directly beneath the mount plate. The bottom channel

is riveted to the frame and has nut plates at attachment points for

the secondary channel which sits on top but is offset to one side

for proper positioning of the fuse box. It can also be

adjusted. The plate mounts to the top of the secondary

channel with screws. The bottom of the fuse box is screwed to

the plate with sheet metal - self tapping screws removed from the

donor Corvette. The harness routes nicely along the underside

of the frame tube and intersects the harness for the ECU running

towards the right side of the engine between the tank and

engine. The harness for the ECU, and the fuse block combine

with rear light wiring and power cables for the fuse box. All

of these wires flow down the right side of the engine, across the

top of the thermostat housing and down into the tunnel area where

the rear #2 ISIS Powercell mounts.

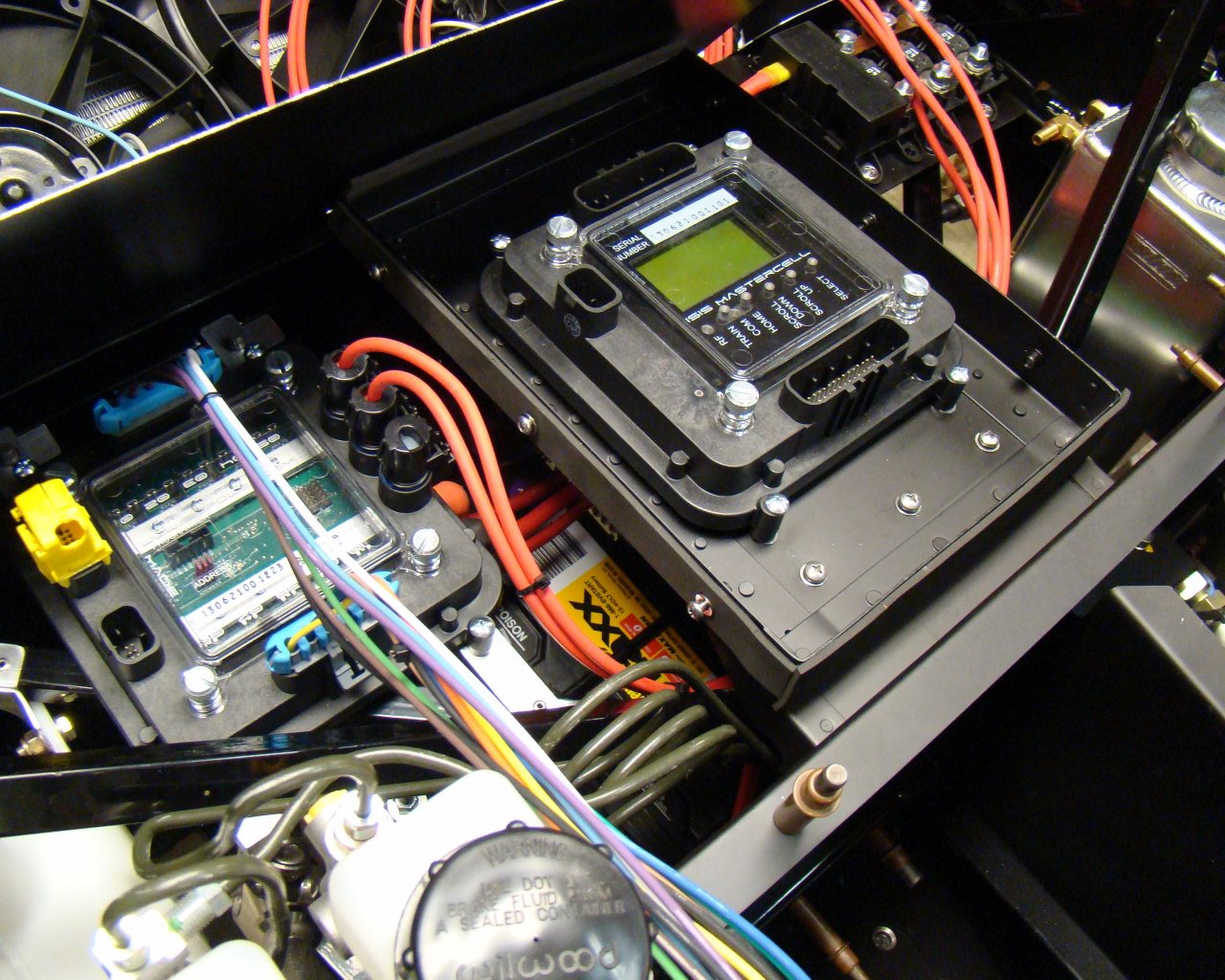

In addition to the engine harness I've been installing the ISIS

multiplexing electrical system. Much of the current status is

shown on the CHASSIS and ELECTRICAL page. Along with

completing many of the wiring schematics using AutoCAD, I've hand

fabricated the mounts, covers and brackets for the forward and aft

Powercells and have begun routing the wires.

8/12/13 - Working on

the traction control and chassis wiring. I've spent weeks

routing, re-routing, chafe proofing and insulating wiring.

I've decided to use the GM Delphi Metri-Pak plugs, terminals and

weather seals where IO can. I ordered the correct tools and

terminals from Ballenger Motorsports (http://www.bmotorsports.com/shop/ )in

Mechanicsville, VA. Un pinning the leftover C5 plugs was

easy. With the correct crimp tool, installing the terminals and

weather seals is easy and provides superior connections that are

weatherproof. I used all Metri-pak connectors for the ABS

wheel speed sensors. For the Traction Control I used aircraft

grade shielded double conductor wire. I grounded the

shielding and T.C. grounds to the chassis. I did add a page with

photos of the terminal removal and installation using the Delphi pin

extractor and terminal crimping tool.

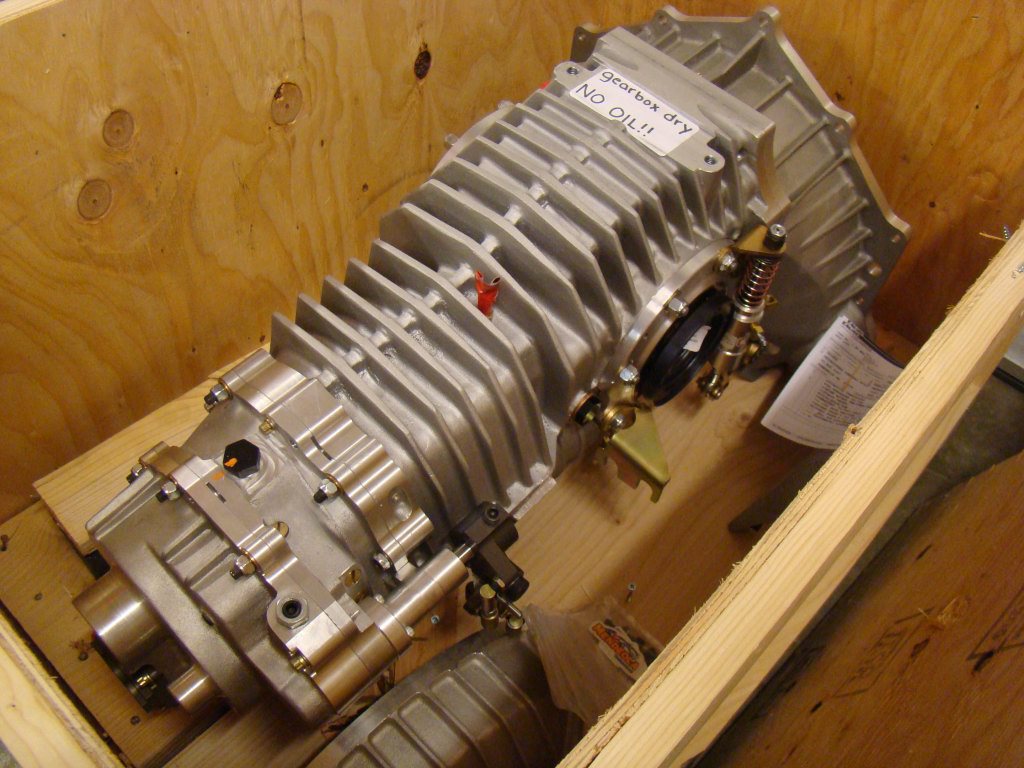

JANUARY 2014 -

Been busy doing lots since August. After a year I received

the Mendeola. It's a beautiful piece of work and mated up

perfectly. I had some slight trimming to remove material

between the throwout bearing shaft housing and clutch face.

Not a big deal and there's plenty of meat around the shaft to not

be concerned.

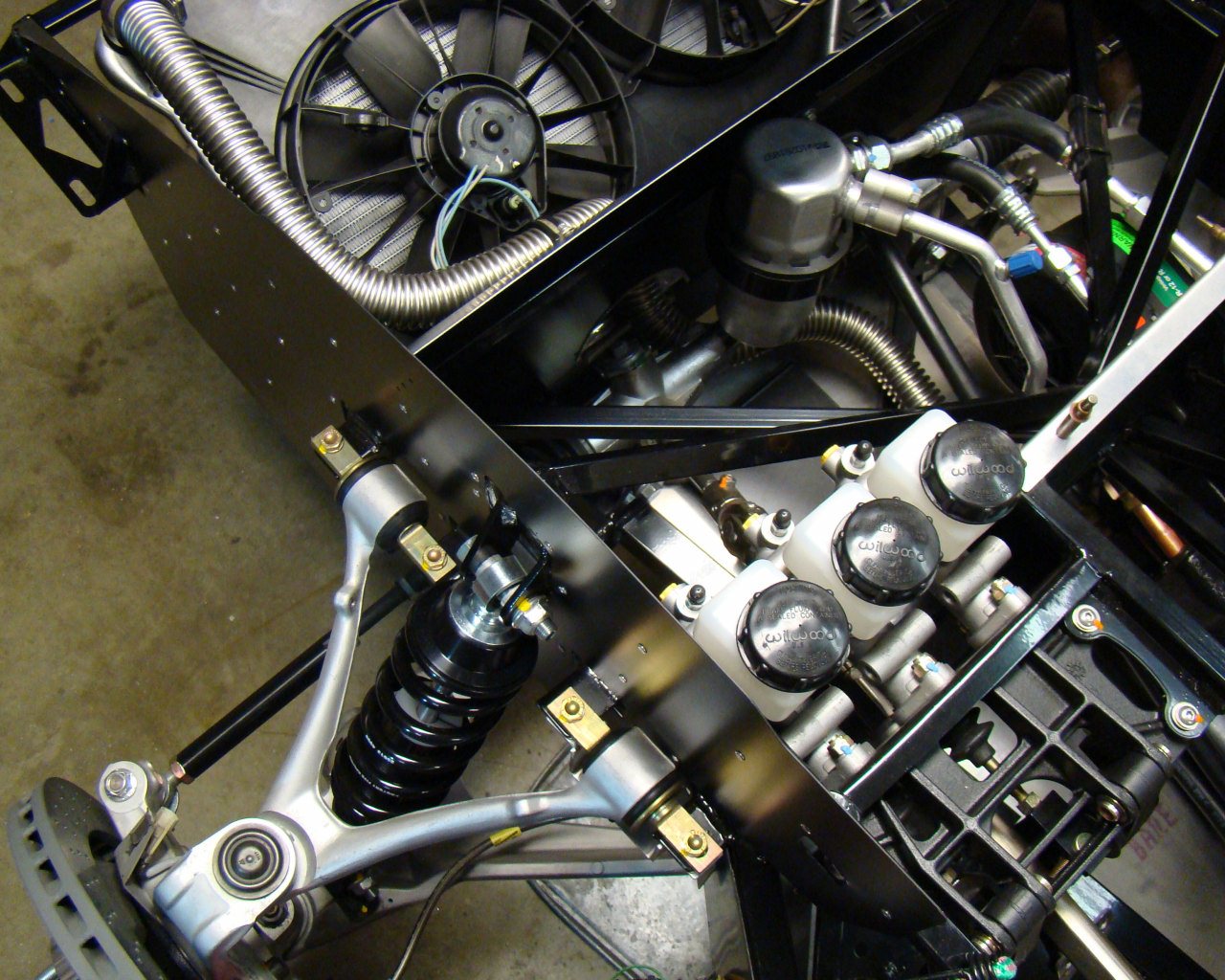

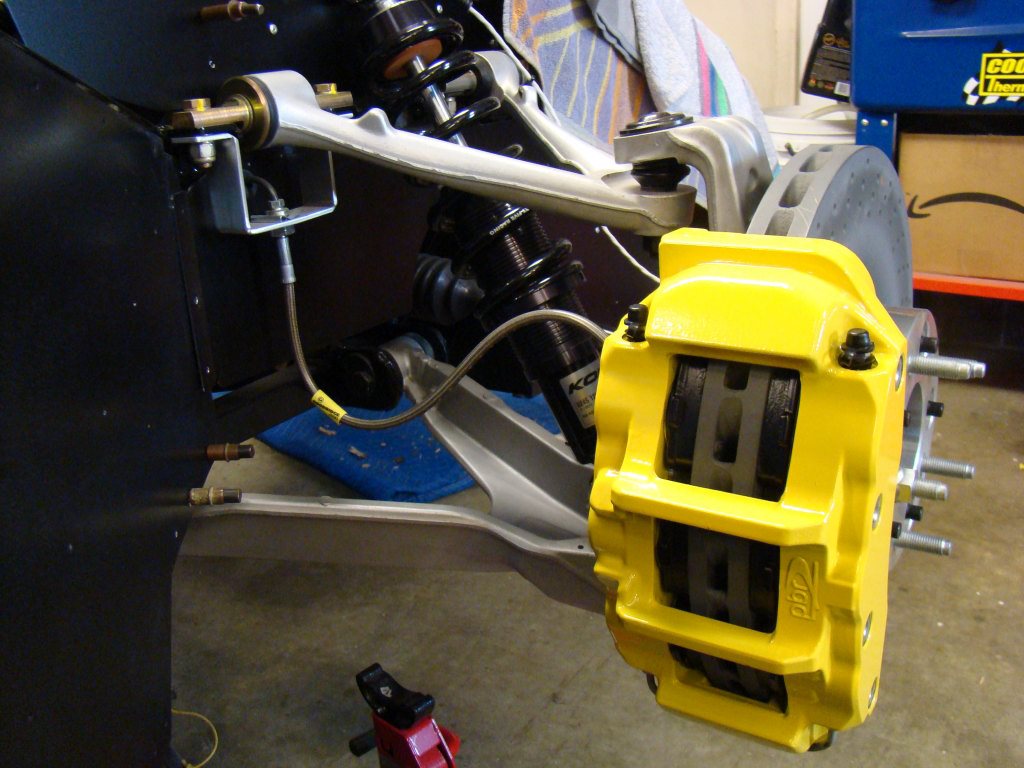

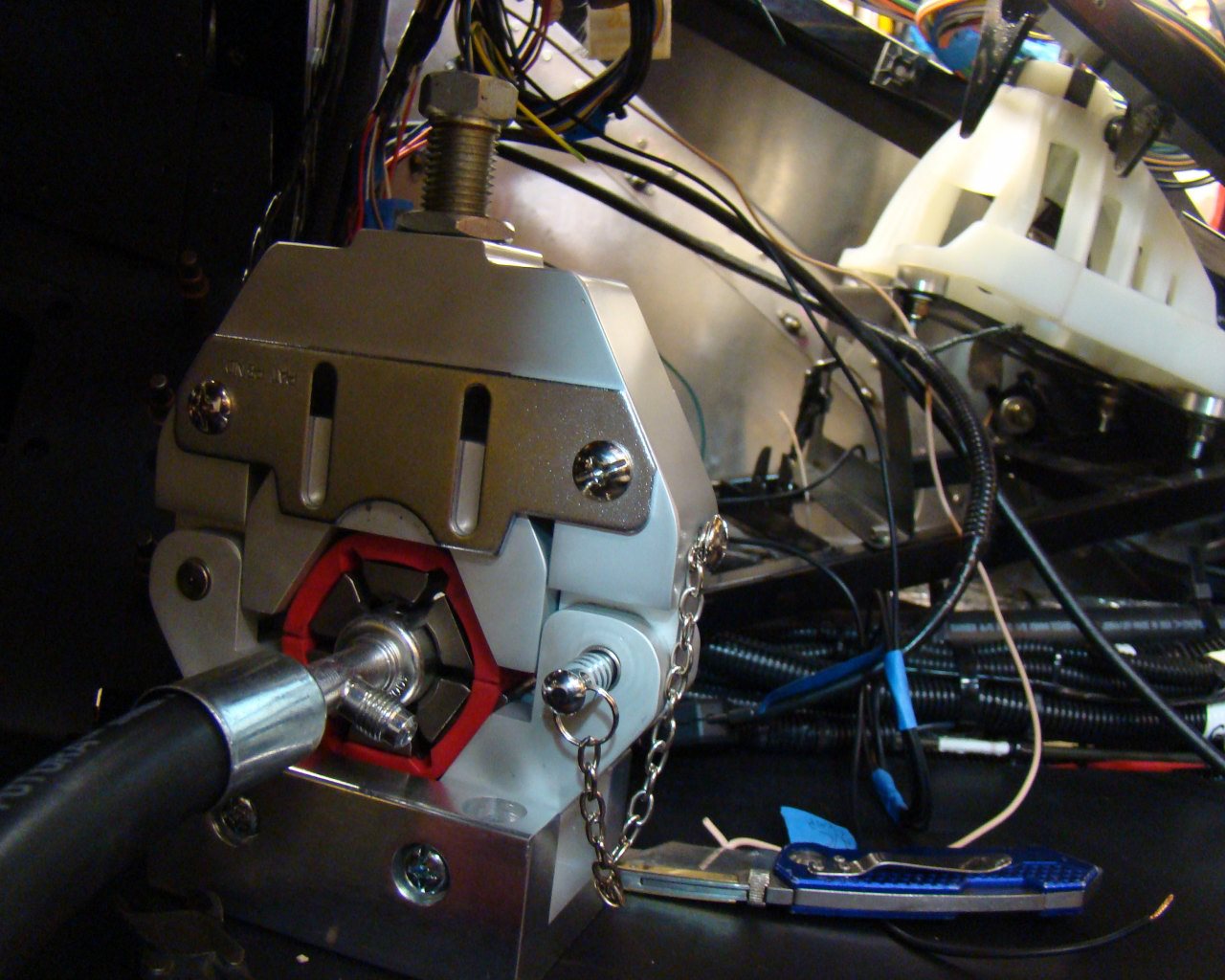

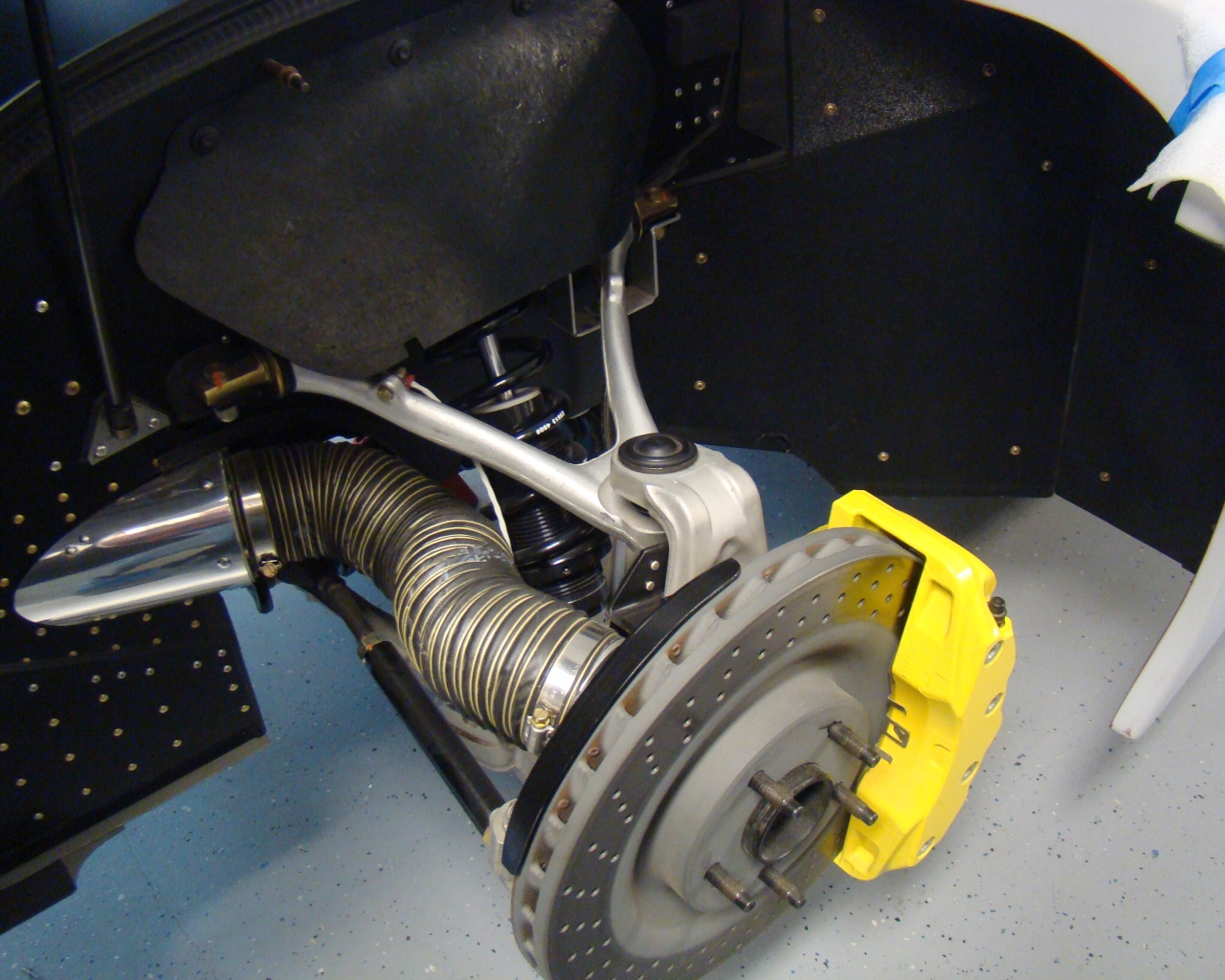

I've also done

quite a bit of work on the electric, shifter, aluminum panels and

also refinished the brake calipers in Viper Yellow Poly

paint. Clutch is in and brakes and clutch are both bled and

working. I tested the electrical, ISIS and Racelogic

system. Also cranked up the bluetooth OBDII diagnostic tester

and it worked without a glitch. All connected to a laptop so

I can finally start viewing everything on the screen. No

surprises except that on the initial ignition power check, I

cranked the engine momentarily. Apparently there was some

fuel left in it somewhere. After all the work and sitting for

a year, it started and ran for about 4-5 seconds and shut

down. Long story short....everything seems to be on track and

working like it should. I've added a bunch of photos (about

90) so make sure to check the pages for photo

updates.

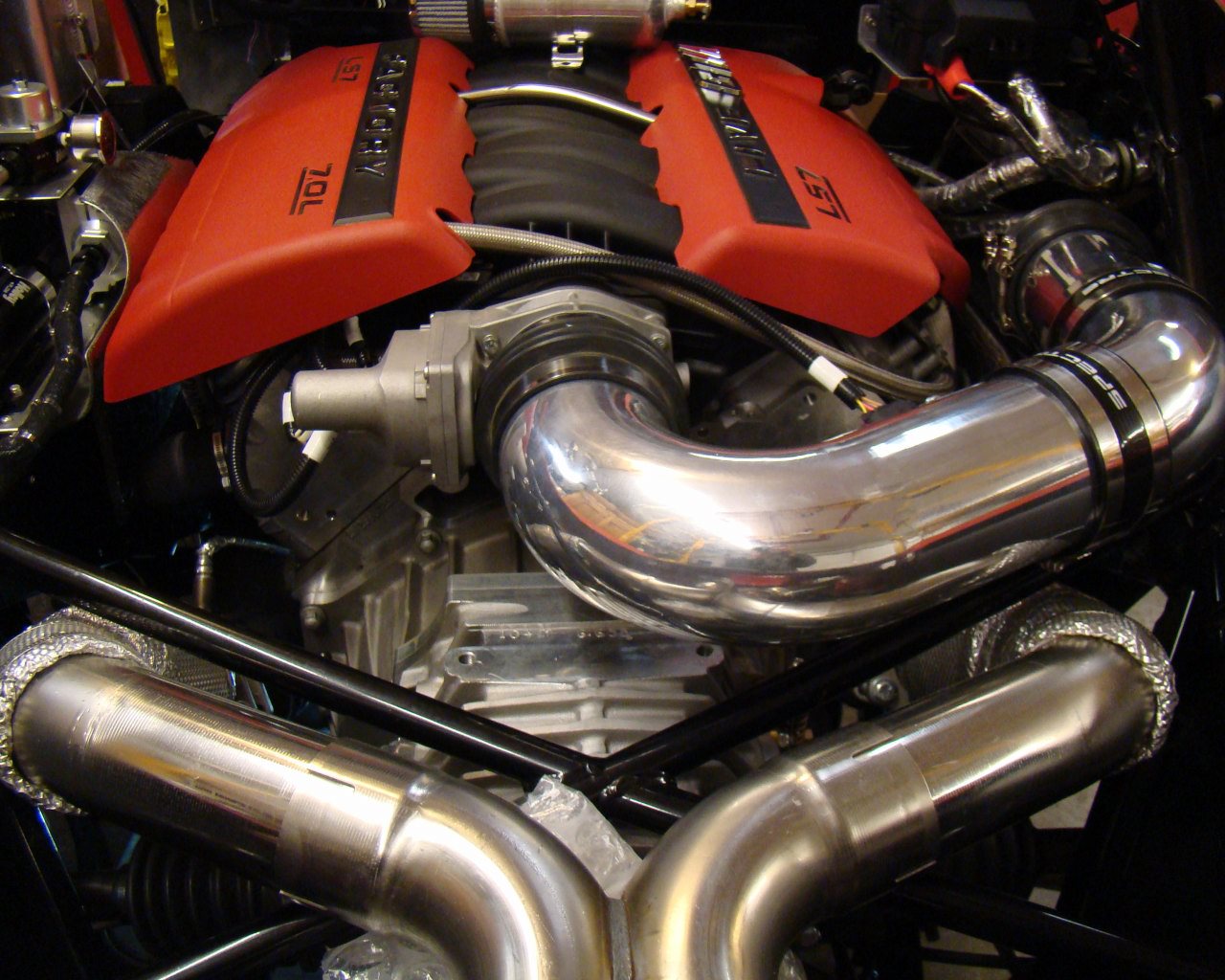

February 1 2014 -

I rearranged some of the engine compartment to make room for the

intake outlet. The dual cold air intake system doesn't work

well with the Kooks exhaust so I'm ditching it for a single 4"

intake. I've added a page detailing the fabrication of the

intake (Here) to include the specific measurements needed for

proper MAF location. I've got to find a location for the dry

sump tank catch can. The relocation of the engine compartment

fuse box worked well but makes it pretty tight for the catch can

which used to be there.

April 10, 2014 -

Lots going on. I ended up sending the ISIS system back for

re-programming to accomodate the "In Net" box, giving the car a

WiFi interface for future PC based programs, flat screen and

Iphone/Android capabilities. The car electric system will be

accesible via the In Net website hardwired into a box in the

car. The system can be reprogrammed and updated via internet

downloads from ISIS Power web site. With the system, A/C and

all electrics are accesible, programmable and capable of being

turned on from any WiFi enabled device via password and user

name. The PC can run multiple Windows based programs to

include engine tuning, GPS, Mapping, Gaming, Music , email and

anything else typically used on a home PC. The unit is made

by "Stealth" systems. Memory and hard drive are solid state

and the system power supply is 12V. The interface will be a

7-10" LED touchscreen with daytime screen

readability.

11 April,

2014 - After lots of research and verification of GTM owner tire

and wheel data, I finally managed to find wheels with the look and

custom options I wanted. I decided to Go with BC Forged HB04

Concave dish wheels from Need4Speed Motor Sports in Glendale

CA. I worked with a fella named Tiko for several moths to

nail down backspacing, size and finish. Unlike many GTM's I

did not go with the traditional Corvette Backspacing or

wheels. I wanted the rear backspacing to provide clearance of

the Big Corvette brakes, with a medium concave appearance and

exactly flush with the side of the car....if not very slightly

beyond so that I can build up a slight flare of the rear fenders

similar but less than what you see on the C6 Z06 Corvette rear

fenders. Visit the wheel page by clicking on the blue links

above. I've added a link to Need4Speed on the links

page. Ask for Tiko and tell him know John sent you. Hhe

was a great help and worked late on many occasions to get my order

correct, communicating the entire time. He also knows the

business and details of options for the high end car market.

Price was excellent at about 4K for the time and ultimately the

finished product.

November 10, 2014

After quite a long break and move I'm back in

action in the garage. I've had the chance to get the garage

built which is a huge improvement over the place we were in.

I now have the room I need (plus some), good lighting and some

other things that make life nice.

Prior to the move and in antiipation of having

to move the project, I got the car running but ran into an oilissue

caused by an incorrect blockoff plate I installed over the oil

cooler supply and return. This plate was sold as a blockoff

plate for that purpose however it did not have the proper oil path

built into it. As a consequence, it prevented full oil flow from

getting to things. I had 25 PSI at cold idle. A long

story short...ithung with me for the move until I got things in

place to begin the troubleshooting process. I went through

the system, all the new components, the gauges etc and found

nothing. After researching flow a little more specific to the

oil path, I discovered the blockoff plate issue. This caused

no damage because oil still flowed in limited quantity past the oil

restrictor (which was there and undamaged as verified using a

borescope). I was halfway through pulling the engine and made

the discovery prior to unbolting the transaxle and lifting the

engine out. That last ditch effort paid off. It cost me

$10 to get the new plate. Everything is good to go

now.

I've added a page with video (Good QualityHD) of

the engine runand a walkaround of the project in it's current

state. I'll start posting pictures soon now that I've managed

to get the website back up and accesible.

More Later

NOVEMBER 14, 2014 (NEW) - Garage

Alignment video on suspension

page.

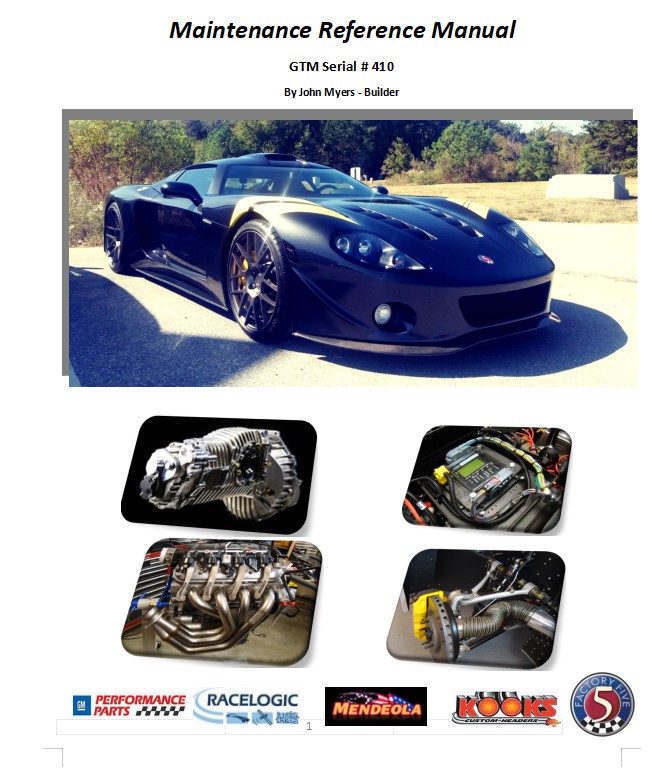

Today was the first test drive in the

go-kart. After doing a garage alignment using scales, rulers,

tape and a protractor, I set out on the road to test things

out. Everything worked as planned and of course I had gone

through everything with a fine tooth comb so I didn't expect any

issues with the engine or electrical. The main thing was to

see how the transaxle shifted and how the engine, clutch and

transaxle acted under power. It was pretty sporty. Nice

and solid and tracked perfectly at 30-40 MPH. After the run,

I let her cool down and then pulled the gauge group to begin the

body work.

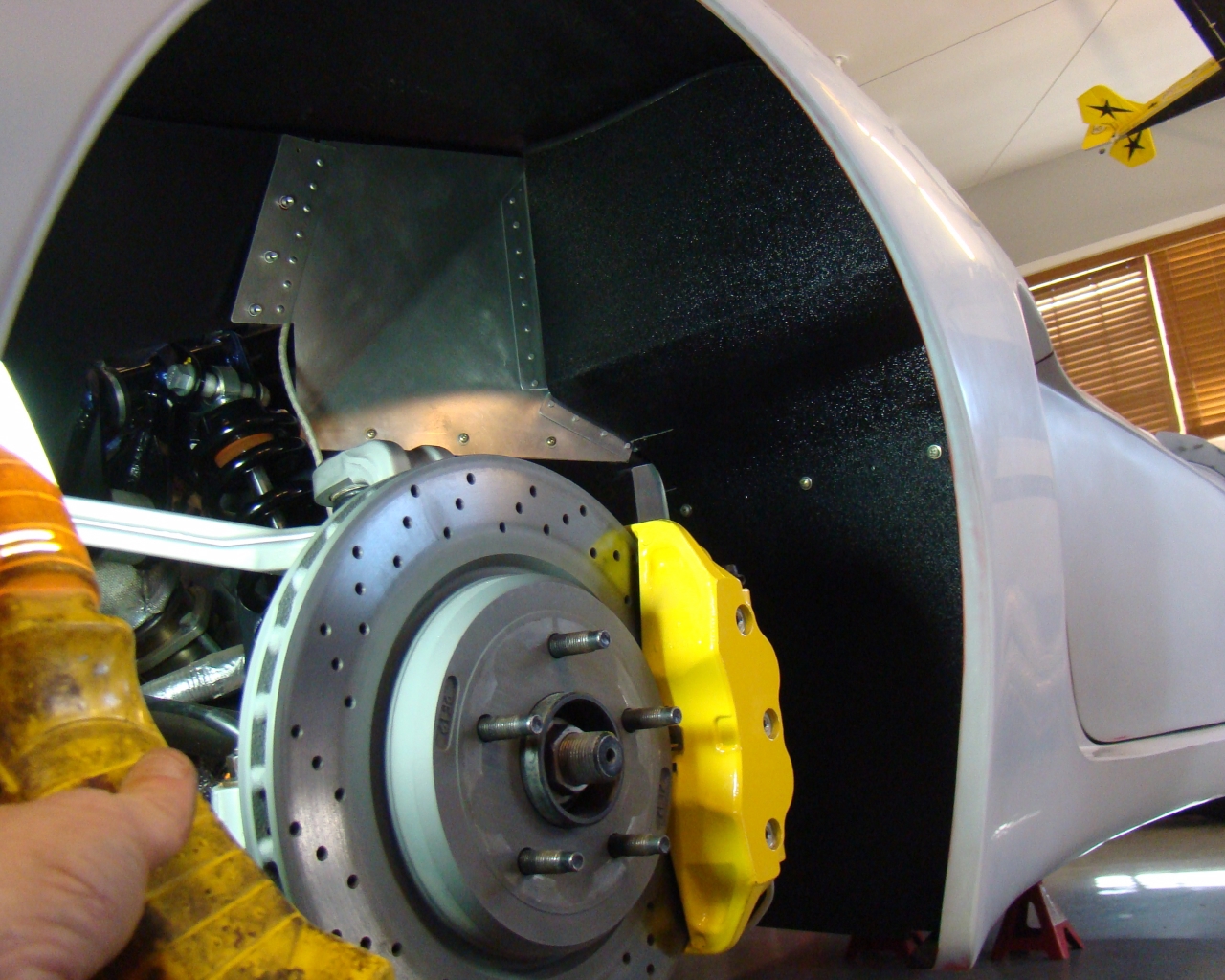

NOVEMBER 14,

2014

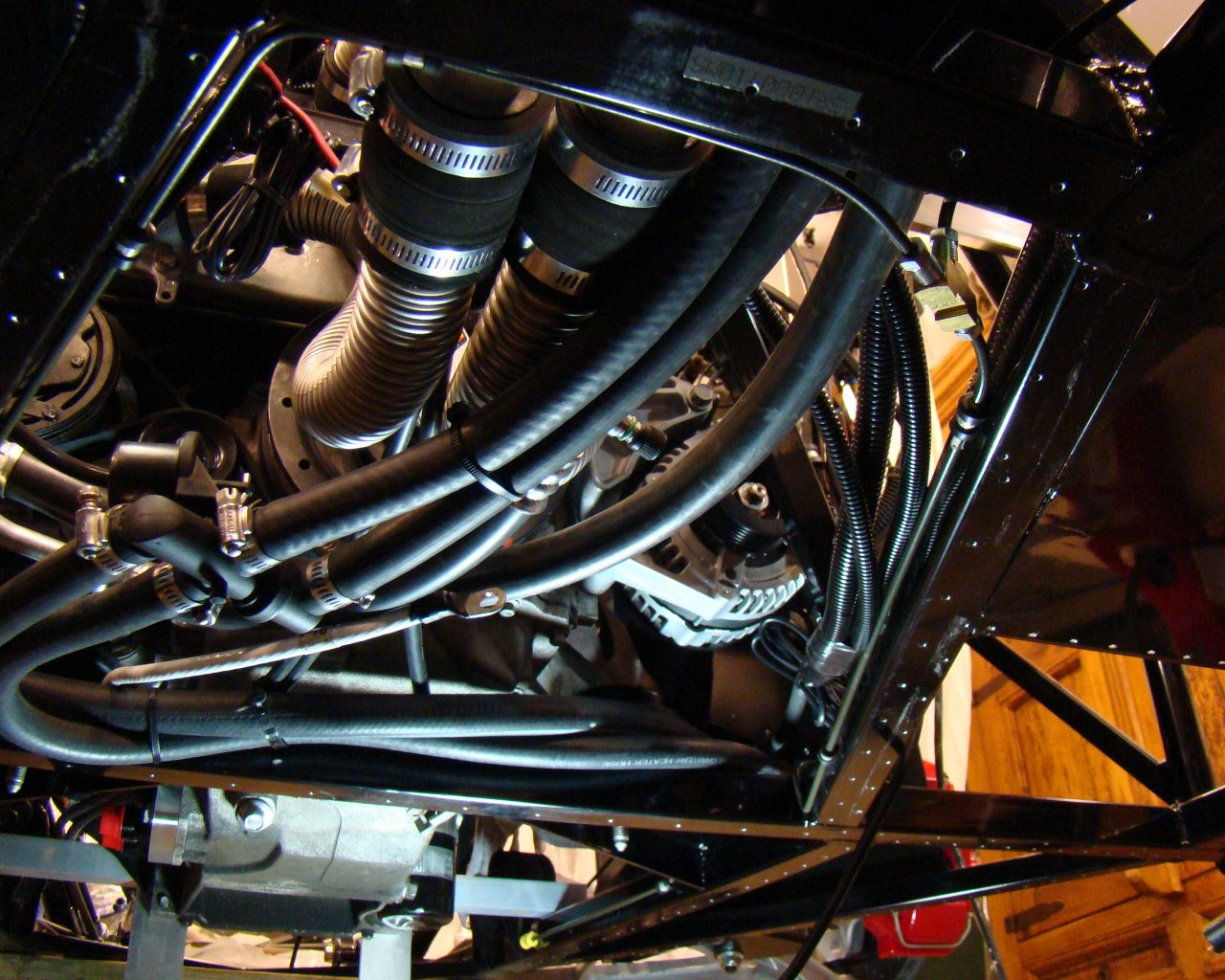

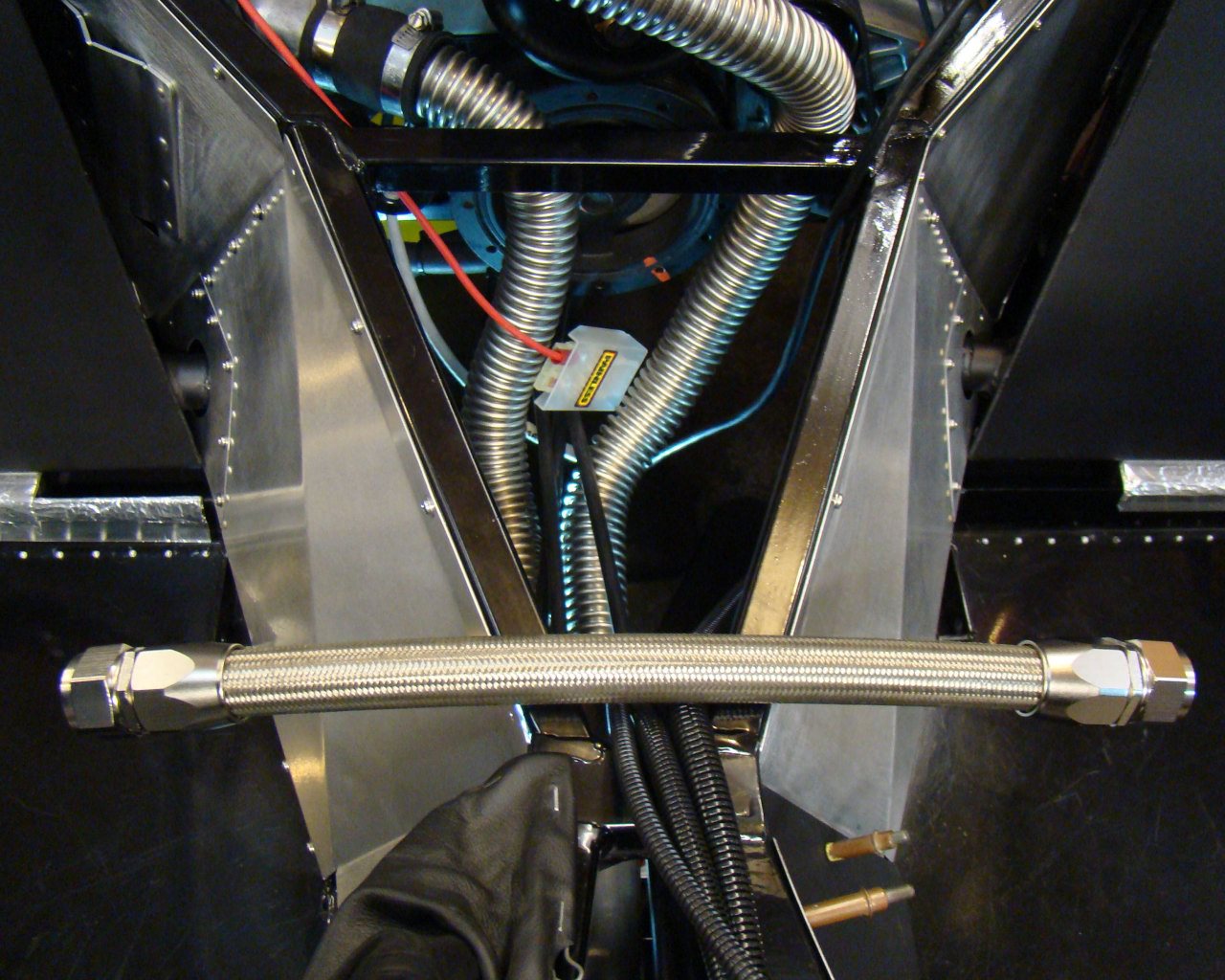

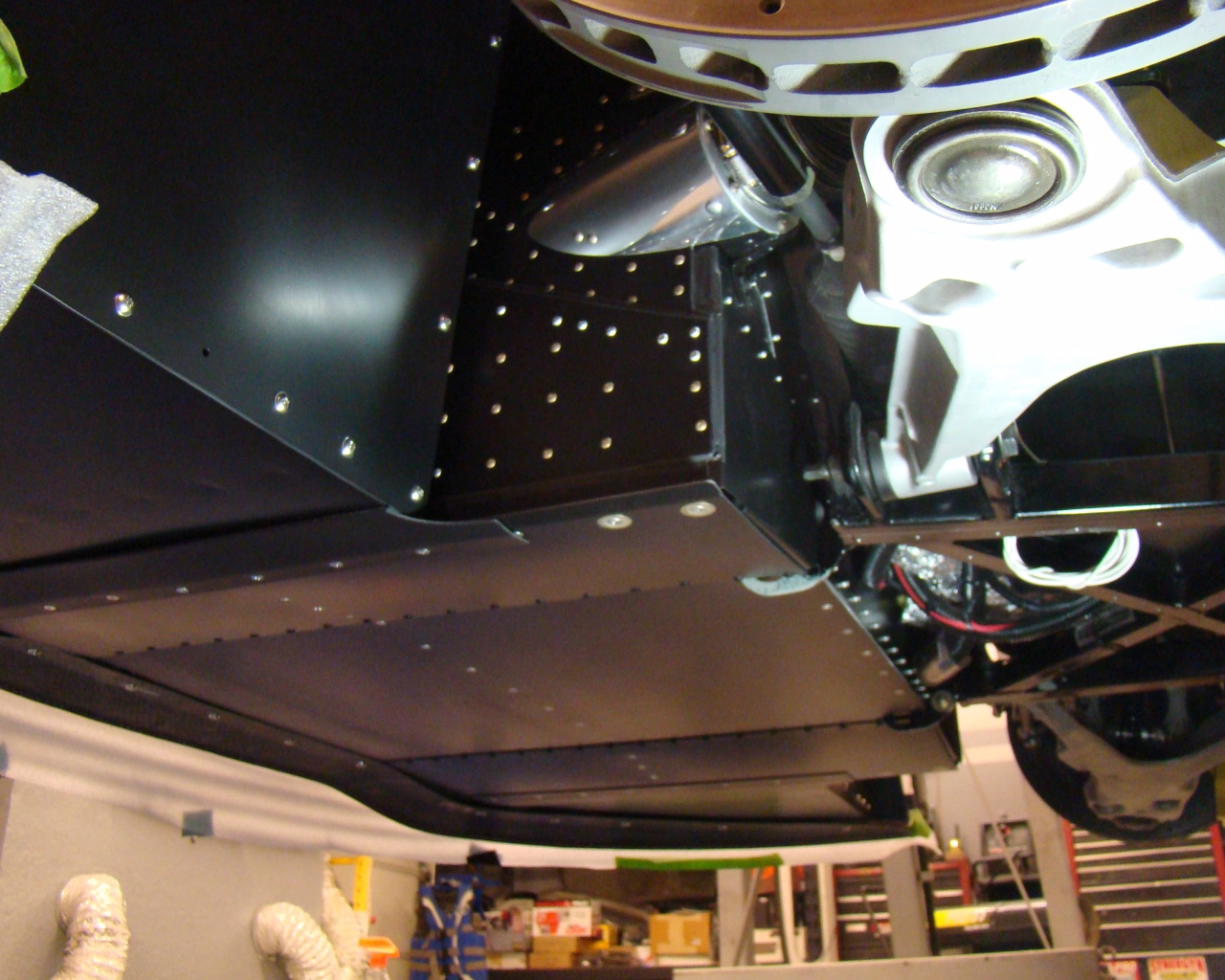

Here's some garage shots with the GTM

up on the new lift just prior to the test drive. I ran the

Mendeola through the gears and ended up adjusting reverse

slightly. The pictures provide a different perspective -

laying on my back with it up on the lift.

...And up on the

lift....

JANUARY 21, 2015 TEST DRIVE WITH BODY ON

BELOW

DOORS:

The time has come to play with the doors.

This is the nightmare on the GTM. Commonly known as a royal

freaking PITA. Not so much because I can't deal with it but

more the fact that FFR has not improved anything in the Gen II

after years of issues in the same area on the Gen 1 GTM. IMO,

A bit to be lacking when asking the increased cost of a kit now at

$25K.

Basically, I just threw the book back into the

bookshelf, grabbed the parts and started holding things in place,

eyeballing the more obvious things that needed to be done.

Then, step by step I walked through a completely different way to

get it done. Yes, FFR has some cool kits and yes, mass

producing door frames and fiberglass bodies that fit exactly in

every case could potentially cost a huge investment in machinery.

On the other hand, some of it could have been improved. One thing

for sure, the book needs a facelift and if there was any part of

this kit I'd ask for them to improve, it would be the book.

This is well within the costs of the increase in revenue they get

for the kit. They shouldn't rely on recommendations to go to the

forums. They don't pay for them and to do so shows a lack of

support we're paying for. Part of this frustration shows in

the number of pictures I've posted on this site. They should set up

a builders page and just load pictures and technical advice for

each of their kits. There's a thousand issues they know

deserve it and are common for each of us.

Sure, the GTM may be cheap when speaking of

Ferraris and Lambos but last time I checked 25K could buy some

pretty high quality stuff. When speaking GTM, your paying 25K

for a concept, an easel and some paint....maybe the dream.

All aside, Factory Five should make the changes and adjustments to

both the kit and the manual that by now, could have and should have

been done. The only thing that will make up for this is the dream

and the time invested in overcoming a new headache at every

turn........of the manual pages that is.

November,

2015

Its been a while

since I updated the site but there's been alot of work done on the

car. I've added a few pages and a host of new photos for the

drivers door, lights, diffuser, fender wells and Mendeola oil

cooler (Setrab w/ Tilton pump). Enjoy. I hope they

help..

November 23,

2015

I

spent the latter two weeks this month contemplating and then

modifying the sheet metal area under the front end. This

should add considerable strentgh but also improve aerodynamics and

cooling. The below pictures show the end result of about a

week of prototyping and then forming various pieces that now make

up a removable front end belly panel that conforms to the

splitter. I used aircraft hardware and formed the pieces with

.063 and .080 6061-T6 aluminum. Check out the "Nose Sheet metal"

page for step by step buildup. BTW...I inadvertantly deleted

the photos of the very beginning which consisted of making the

templates for the .063 sheet metal 3-piece panel but you can still

see the end result. All templates for the individual pieces

were made from cardboard and traced onto the sheet

metal.

December 27,

2015

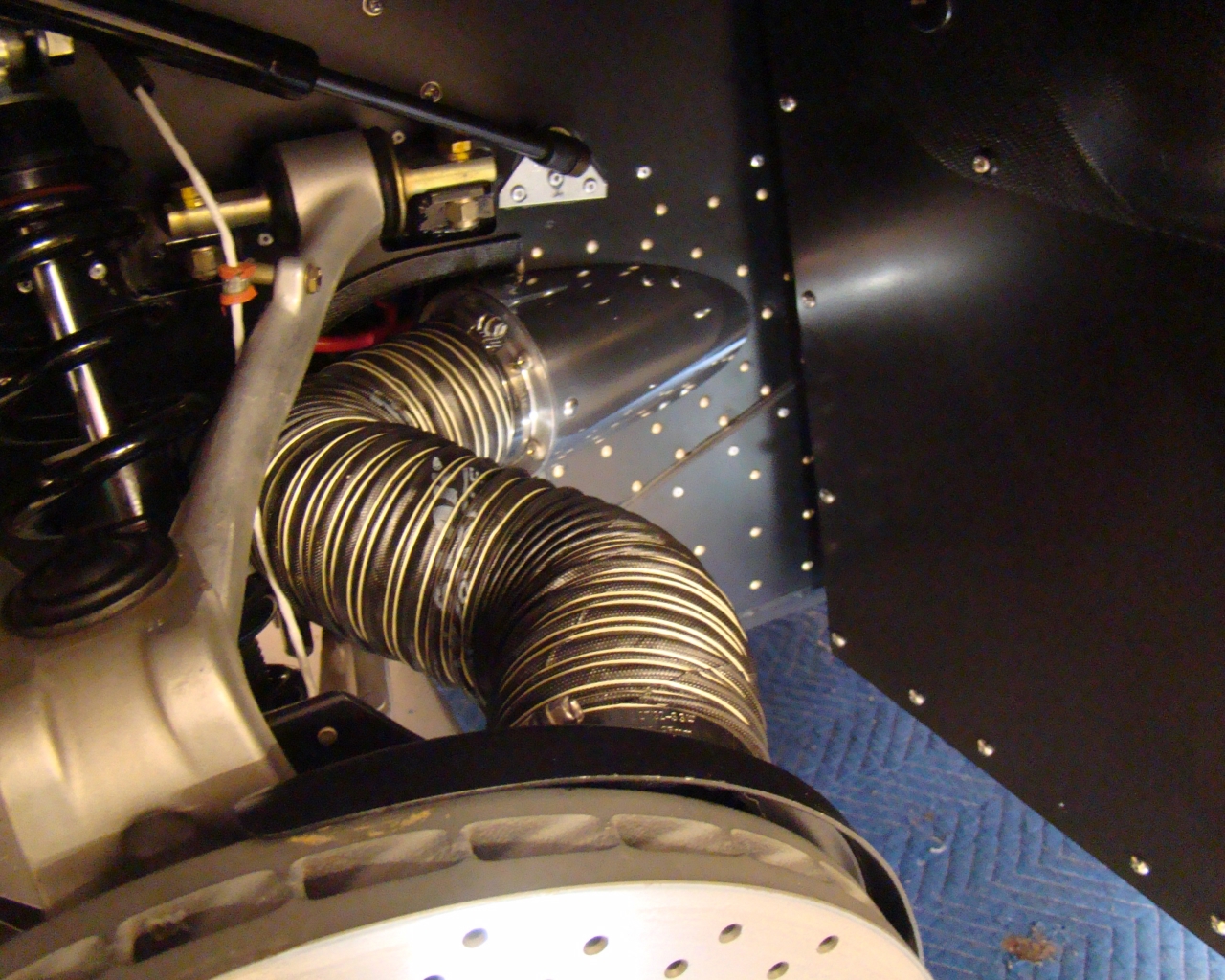

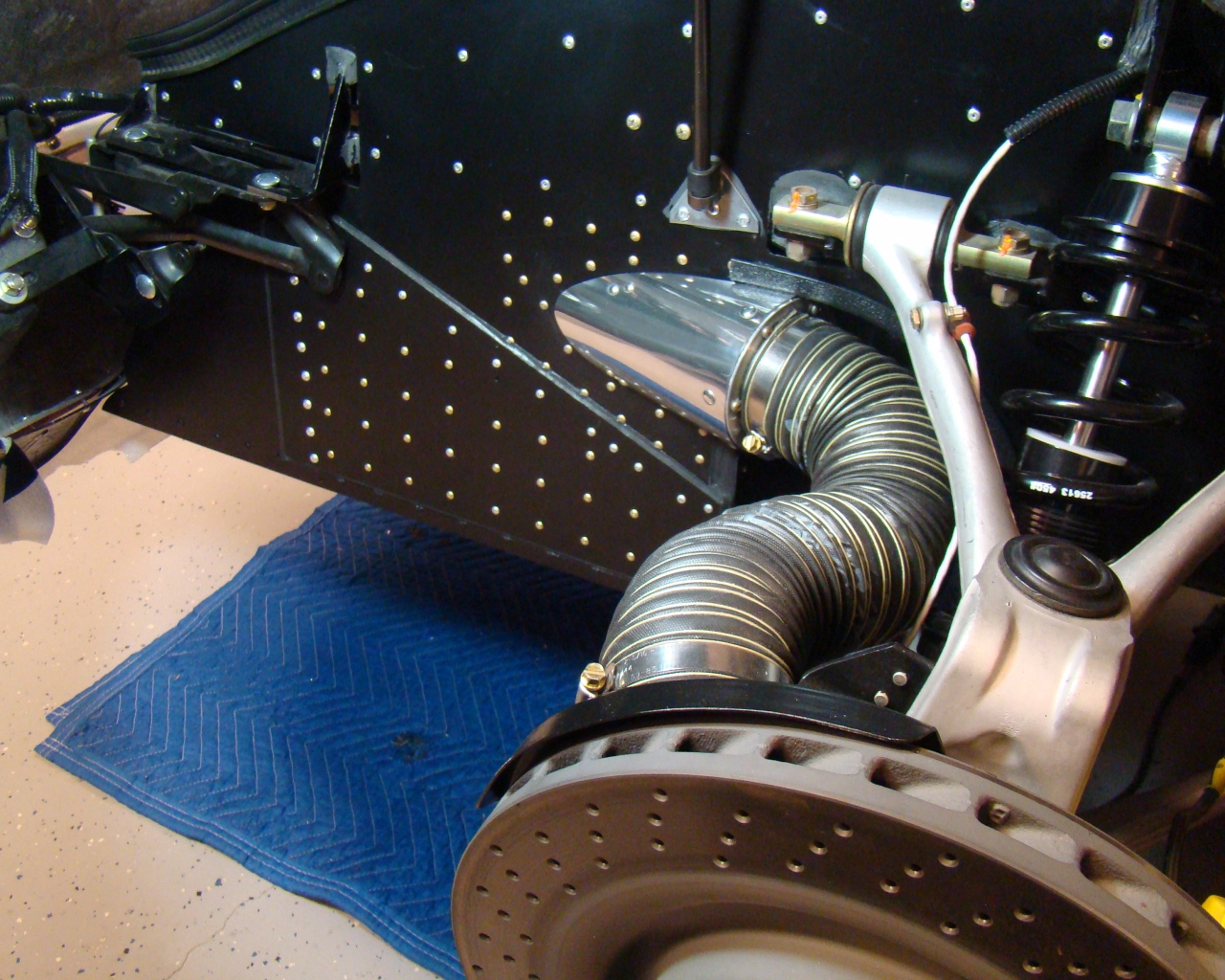

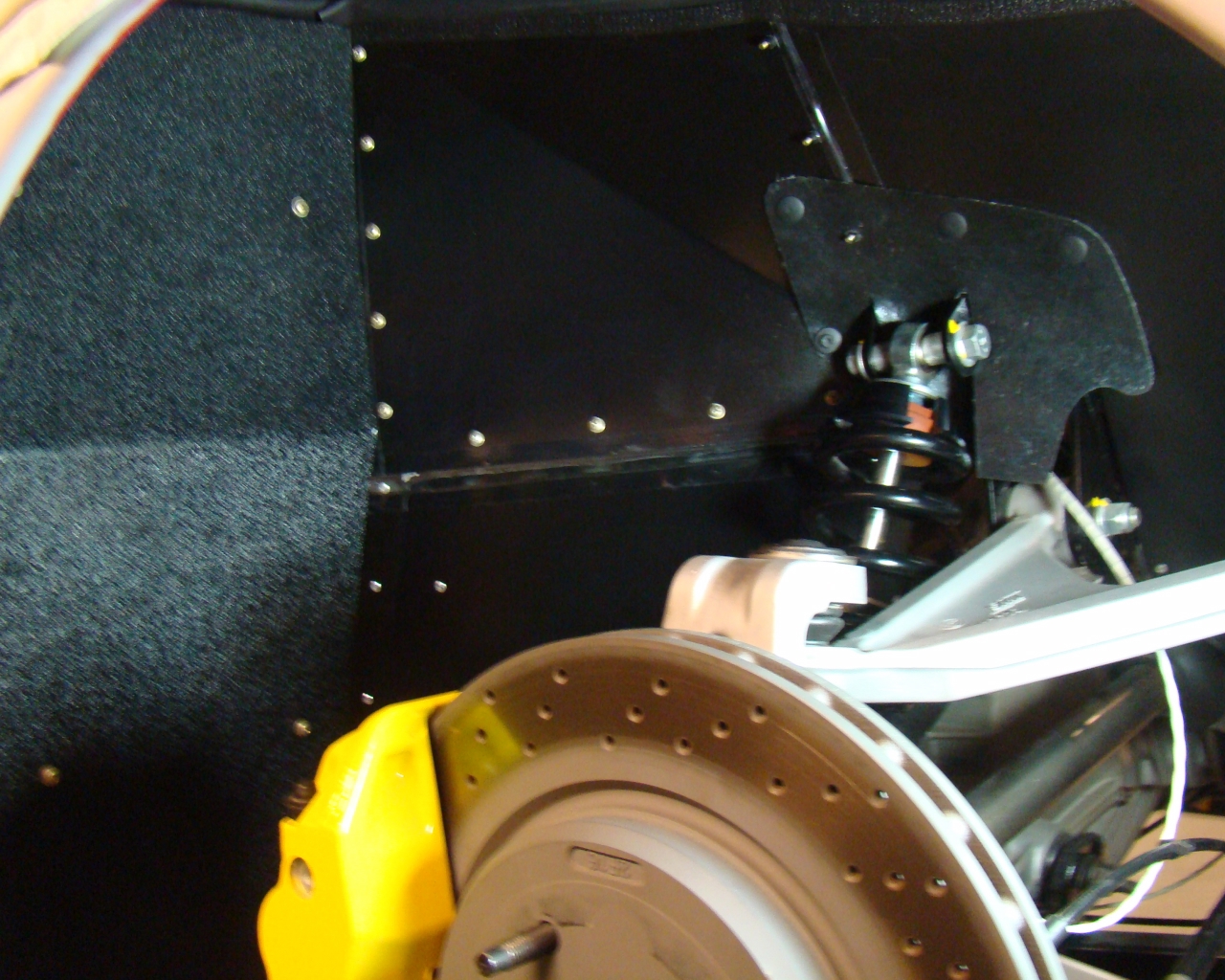

Spent a few days

designing and mocking up a brake cooling system to take some of the

excess radiator box air out. There's enough air passage

around the radiator and with all the excess cooling air above the

radiator, I was able to get this done without interfering with

steering or suspension articulation. See all the details on

the "Brakes"

page

January 15, 2016

Finished nose, forward undercarriage and brake

cooling modifications. Finished in Epoxy two part flat

primer. See "ALUMINUM PANELS" and "BRAKES

PAGE"

March 7,

2016,

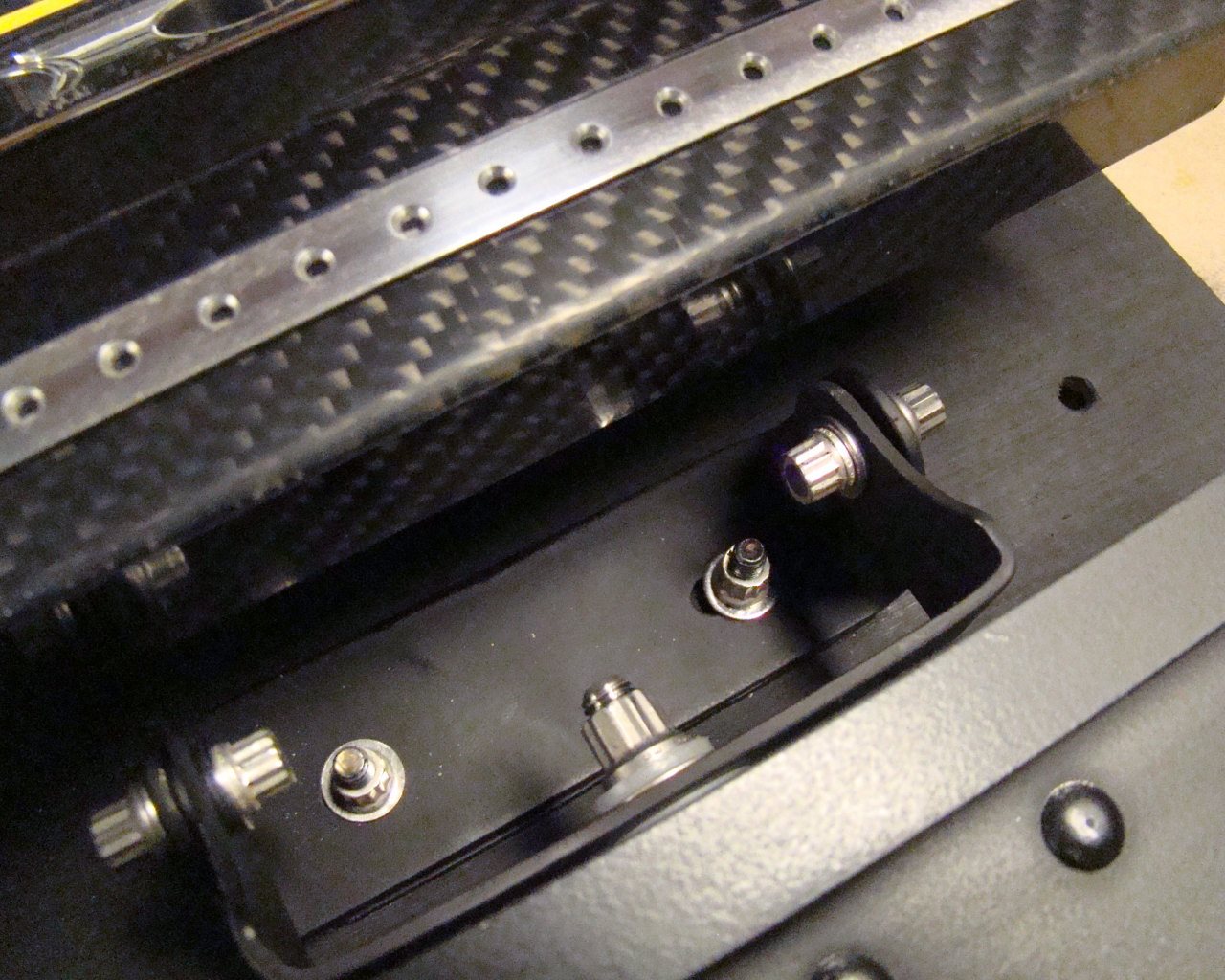

While trial fitting the

interior I noticed the realestate was somewhat crowded for the

traction control, switches and some of the other stuff. I

figured an overhead console would be worthwhile to move some of the

stuff up to the cieling. This removes all switches and leaves

only the primary (3) gauge group and the PC flat screen I intend to

add later forward of the shifter. The tablet is a Samsung S2

with a housing I fabricated with aluminum channel. I also had

to mold the buttons. I ran a yellow stripe across the flat

Carbon Fiber after noticing some transition issues between the bond

lines of the CF. I say "Flat" because I liked the look of the

CF after hitting the gloss epoxy Gelcoat with some 1500

sandpaper. It's supposed to go with the yellow brake calipers

and yellow on black stitching I plan to have done later..

Check the "Overhead Console" page link above.

August

2016

It's been a

busy summer with gardening, going to the beach and body work.

I've been fiberglassing, sanding and filling for months. Lots

of very tedious boring work....over and over.....and over again and

again with getting the lines correct, getting the roof intake

glassed on and filling in around each of the glassed on rear vents

below the lights. I'm about to spray the epoxy primer

(Metacryl) - tomorrow morning is the plan. The pictures below

are before and after the Slick Sand coat. It's very porous

put provides a nice high-fill polyester base that helps even out

the shades for sanding while providing a nice gelcoat to finish

sand. Yes, the entire body had to be sanded again from about

100 up to 500. I ended up going over the body again after the

slick sand with a fine grade filler for making minor corrections

and filling in the pits. This is alot of work! Not as much

fun as bolting things together. Gotta be patient and walk

away now and then. It goes on and on. The front end is

the next piece....then the hatch and doors.

I plan to

shoot the epoxy and then place the body back on the car. I'll

doublecheck the front and doors and then determine any last minute

corrections and paint the inside black or coat with a

bedliner. There are lots of little things to check.

Painting the body off the car may present a risk of scratching so I

may do everything except the final color off the car. Then

I'll mount it. I'll shoot the doors and hood off the car - to

include final color and clearcoat. I built a paint booth today and

plan to post pictures later.

I've added a few pictures to the "Aluminum foort Box Panel"

page

September

2016

Still

working on the paint prep prior to beginning the final fitting and

assembly. Months of sanding and my fingers are wearing

out:). Honestly, there are so many lines and curves to

blend. I use just about every imagineable sanding

block. I did glass in the hood vents and blended with the

surrounding surface. That was quite a job but worth the

pain. The other option would have been to bond them down in

the cutouts. The hard part is sanding the transition and

radiuses at each vent opening. They begin at the

surface and flow downward - 4 x for each and that means a total of

16 transitions to worry about keeping radiuses flowing correctly

and transitioning to the surrounding skin. I'm currently done

with the nose (except for final paint) and working the doors

now. All of this will be mounted one final time prior to

removing and beginning the sequence of final assembly. Looks

cool light color but I don't think I'll go that direction.

We'll see.

1/31/2017 Working to get this done by

late Spring. I spent some time looking at the option of

painting the body off the car but don't want to chance the issues

that come with it. Main thing is concern for damaging the

paint, door final fit issues, paint consistency of the front end,

doors and hatch and some other things. As a result I've final

sanded to 400 and mounted the body after wrapping the roll bar and

doing the headliner. Here's some snapshots. Detailed pictures

are in the appropriate places you can find in the above

pages. I added the E-Brake

video showing the replacement for the failing Corvette E-Brake

issue.

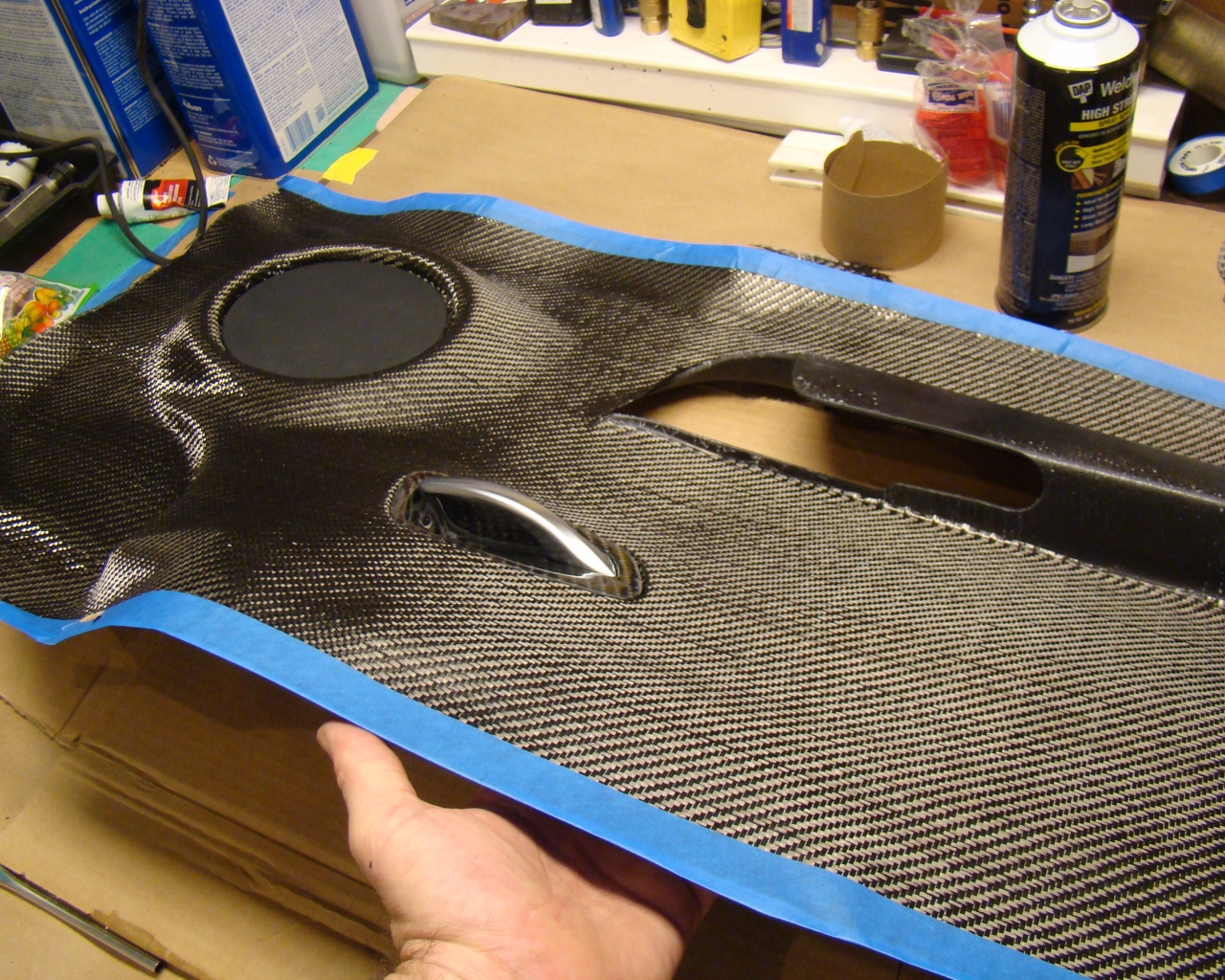

3/17/17 Spent the last two months closing out

the wheel wells and beginning pre-paint work. I chose Smokey

Granite Mica (Lexus) for the color and may do a Viper yellow

stripe. I bought the paint (Cromax) and all paint, sealer,

clearcoat and the 1/2 pint of yellow ran me $1600. As I began

going around the car I decided to doublecheck door fitment one last

time. As I took a closer look at the door panels I realized I

needed to do a little more in terms of mounting the panels before

paint. This turned into a total project to include full

carbon fiber door panels and hand built arm rests which ultimately

required vacuum bagging. Pictures are worth more than words

but I will say it took me a bit off course. What started

everything was the Corvette mirror and door controller that needed

to be mounted. That required the custom arm rest which meant

I had to strip the entire door panel material off and remove the

glue from the ABS. (Not fun but a 40 Grit disc on an orbital

basically vibrated the glue off). I welded ABS left over from

the wheel wells to do the arm rest and then covered with yellow

stitch Carbon Fiber. The panels have three layers. I

have the wheel well work photos in the "Front Fender Wells" page

and the door panels and arm rests in the "Interior" page. The

door handle was relocated and molded into the stock door

panel. I used the older panels that had the separation issue

with the material. I still have the improved set -

untouched.