BODY AND DOORS

THE PITA OF THE GTM

THE VIDEO IS A QUICK WALK

THROUGH SOME OF THE AREAS ON THE DOOR AND THINGS YOU CAN DO TO GET

THE WINDOWS DOWN TO A MORE ACCEPTABLE DEPTH IN THE DOOR. THE

PICTURES BELOW SHOW MORE DETAIL OF SOME OF THE SAME AREAS

DISCUSSED.

DOOR - WINDOW INSTALL

CHECK THE PAGE FEATURING WINDOW DETAILS UNDER THE BODY AND DOORS

PAGE

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

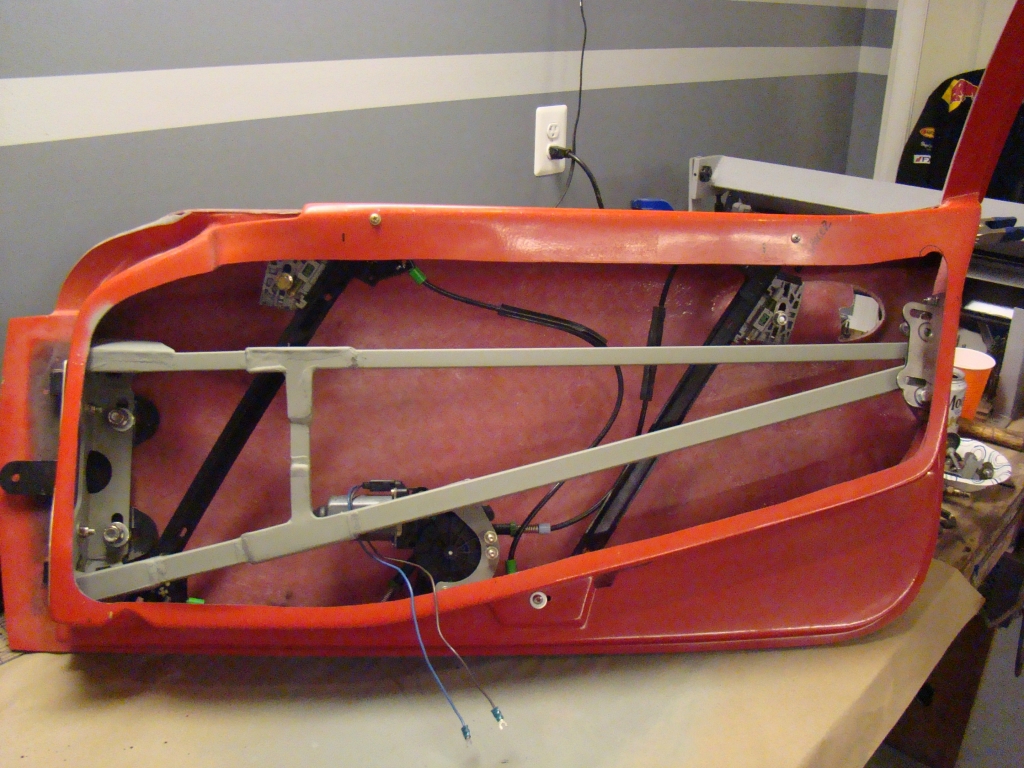

AFTER SANDBLASTING, WELDS ARE SEALED WITH STRUCTURAL

ADHESIVE. THIS IS NOT A MUST BUT THERE WERE SOME AREAS WITH

SMALL PIN HOLES AND I DIDN'T LIKE IT BECAUSE DOORS ARE AREAS YOU

CANT SEE AND IF MOISTURE GETS IN THERE, CORROSION CAN GO A LONG WAY

BEFORE THE NEXT TIME YOU'RE IN THE AREA.

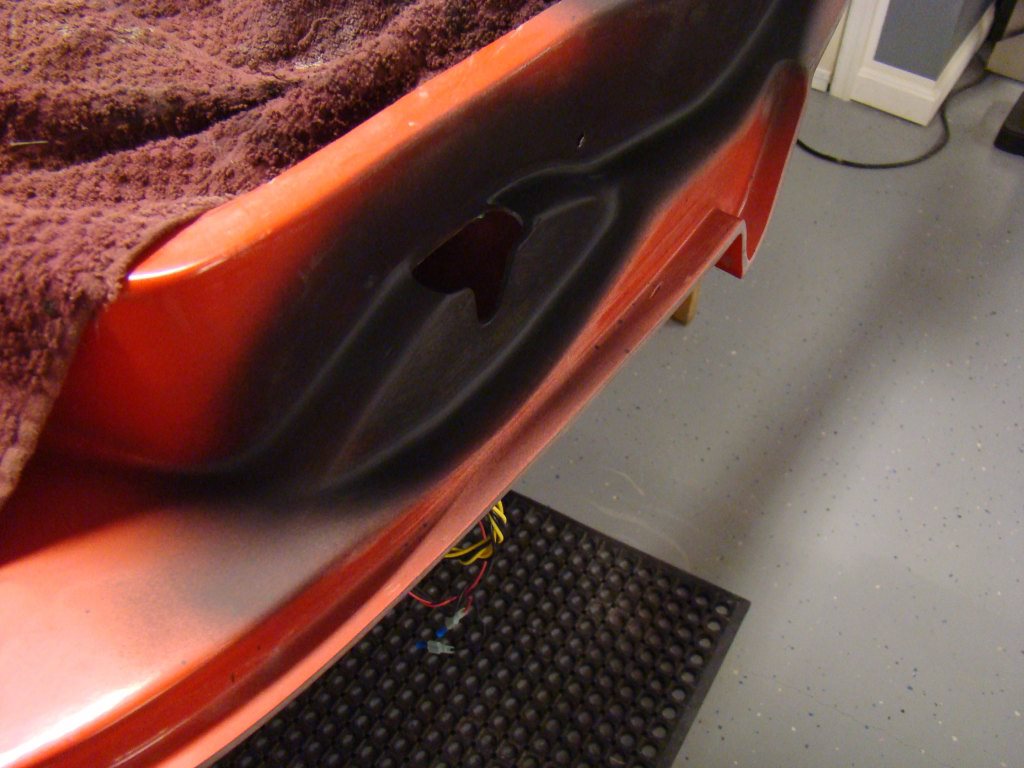

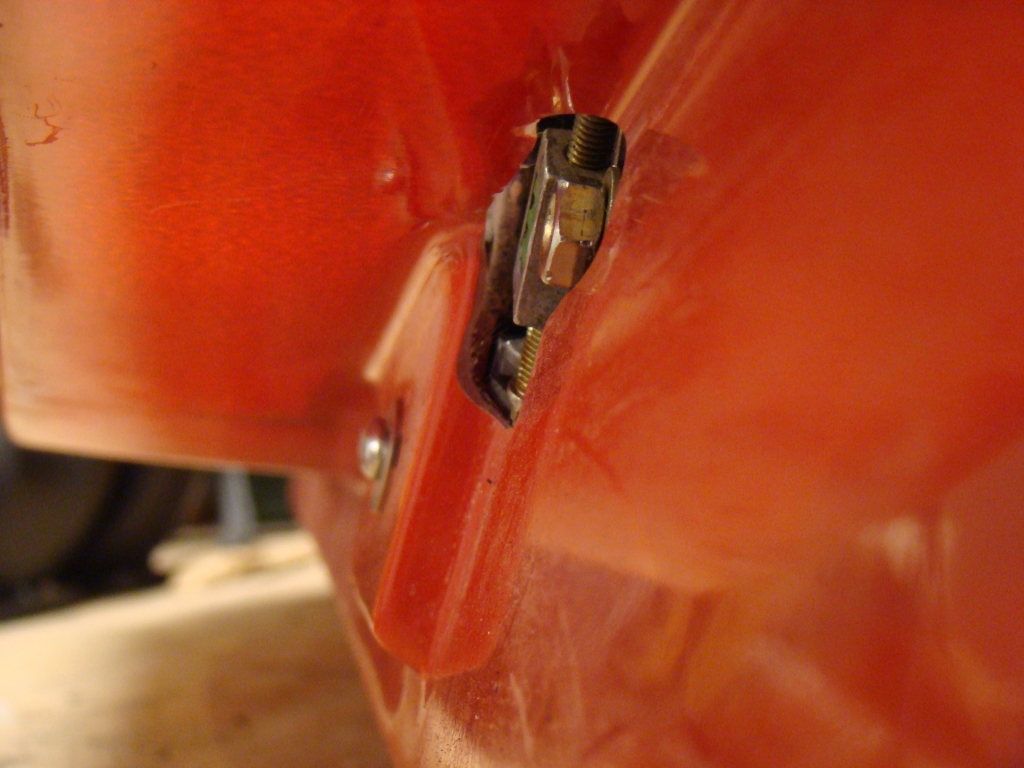

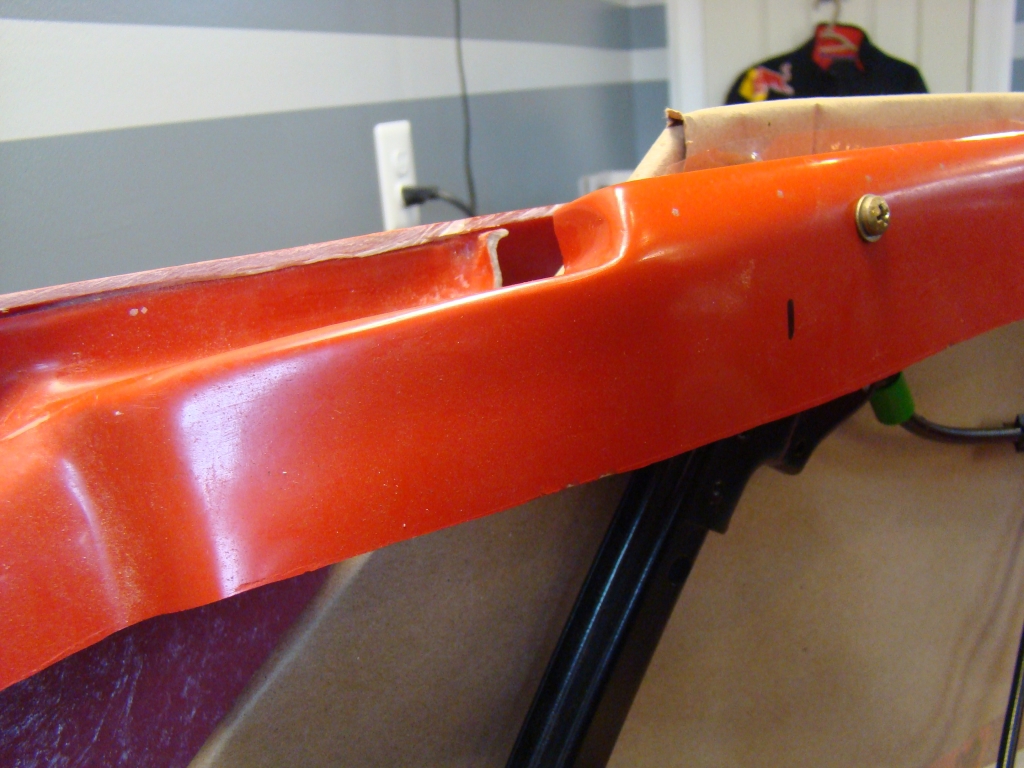

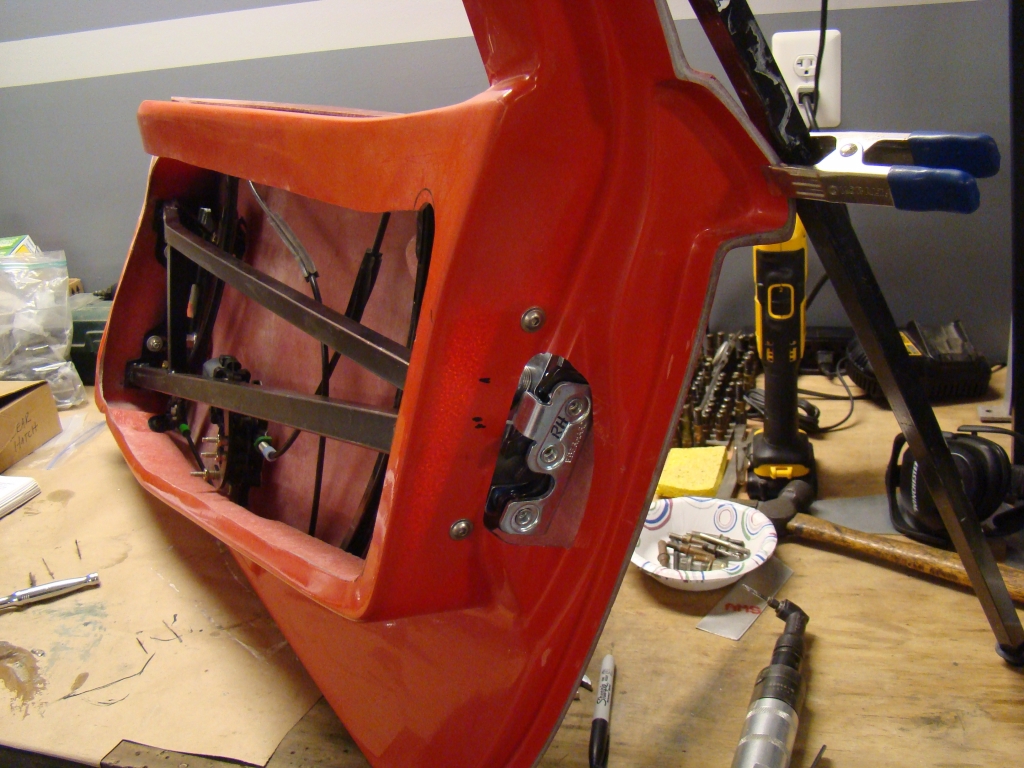

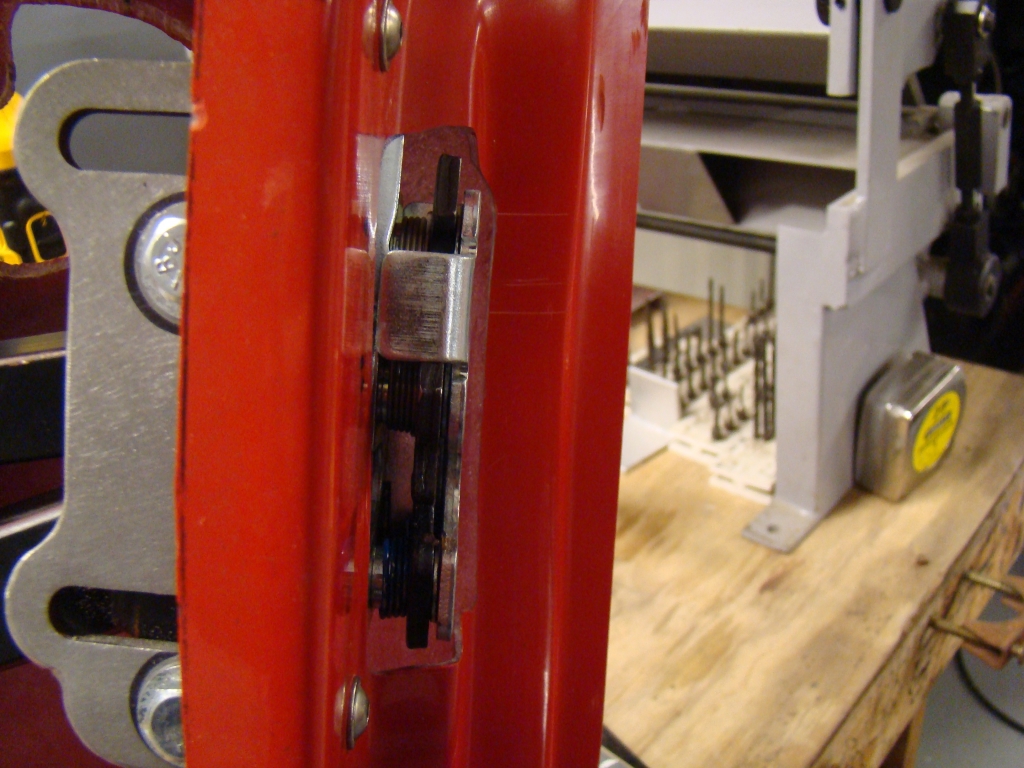

NOTE THAT THE LATCH OPENING STARTED SMALL BUT TRIAL AND ERROR

RESULTED IN A PRETTY GOOD SIZE CUTOUT. I RECOMMEND YOU

PROVIDE PLENTY OF ROOM WITH YOUR CUTOUT AND THEN JUST REGLASS THE

AREA AFTER YOU KNOW WHERE THE LATCH WILL BE PERMANENTLY.

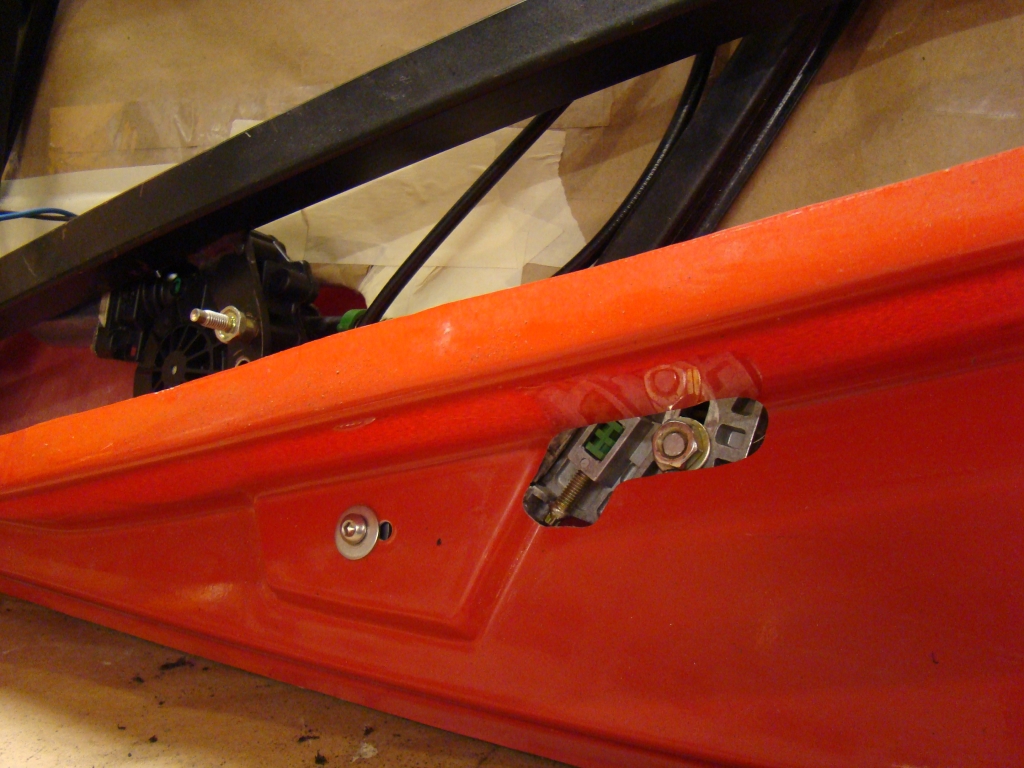

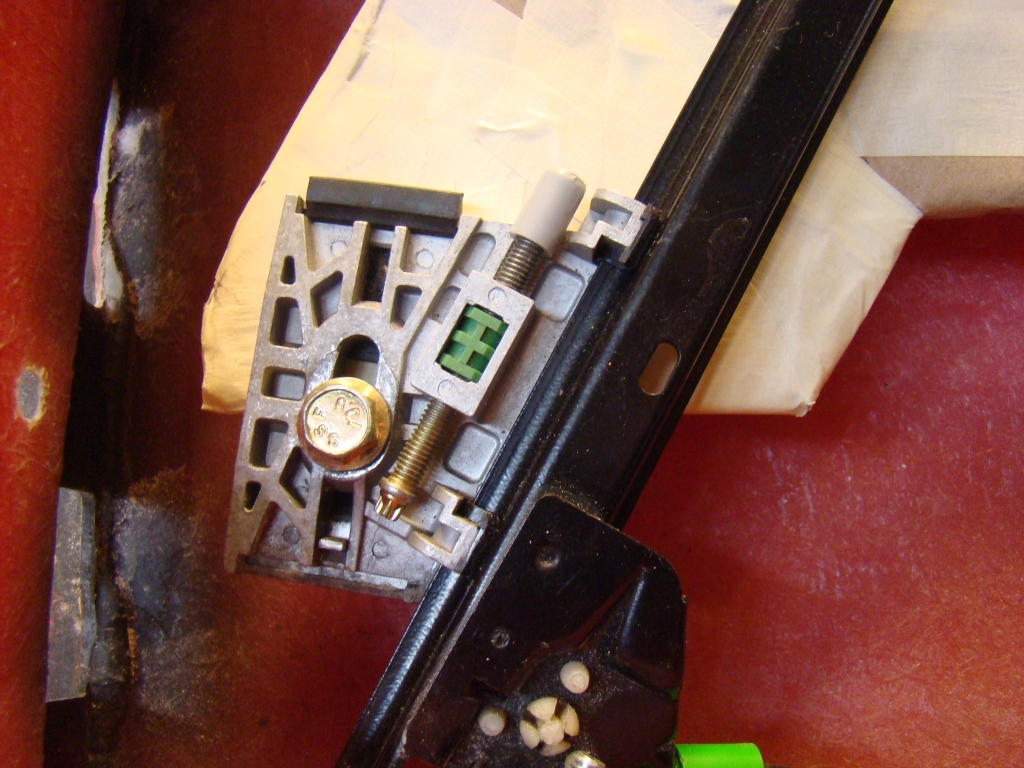

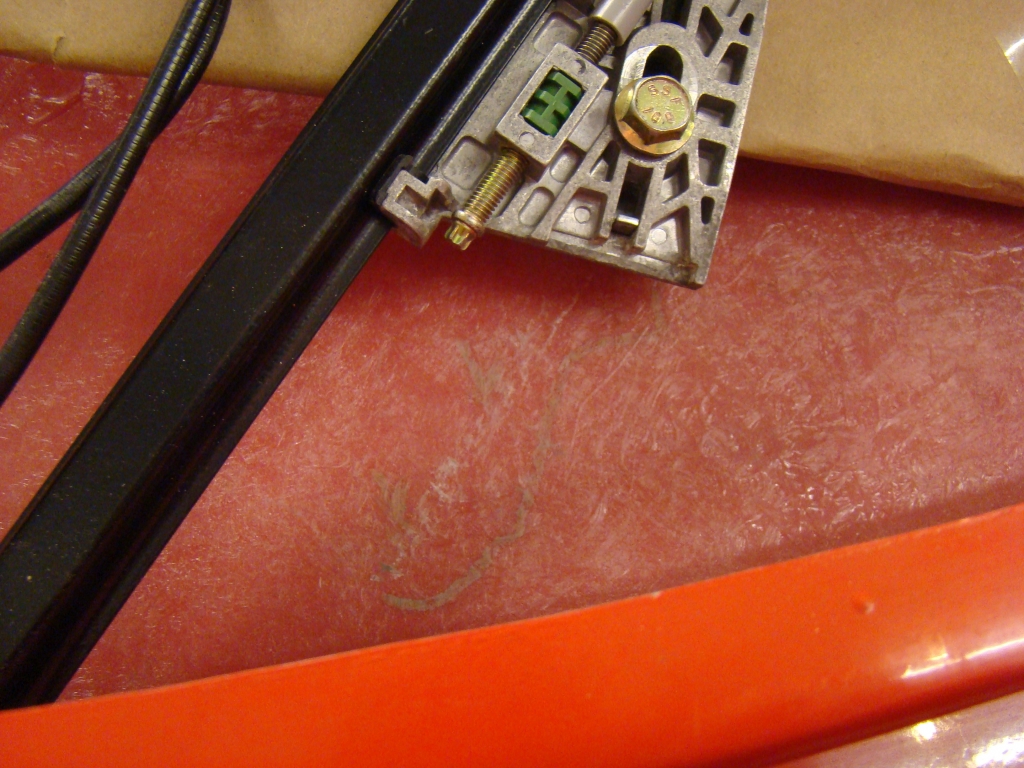

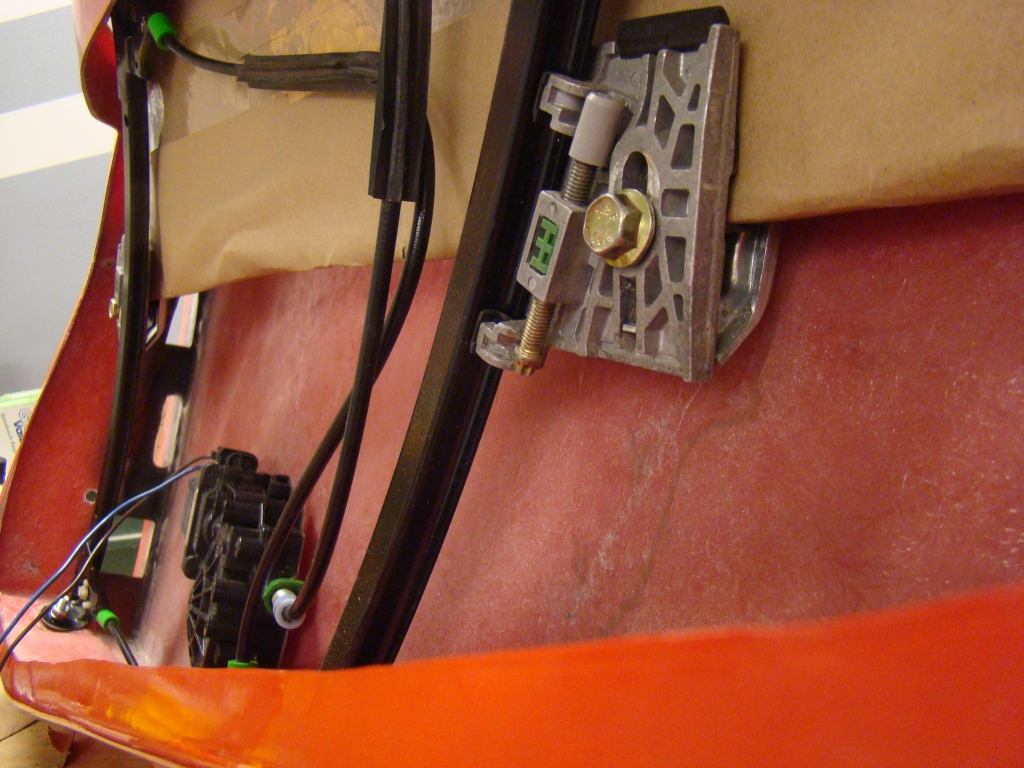

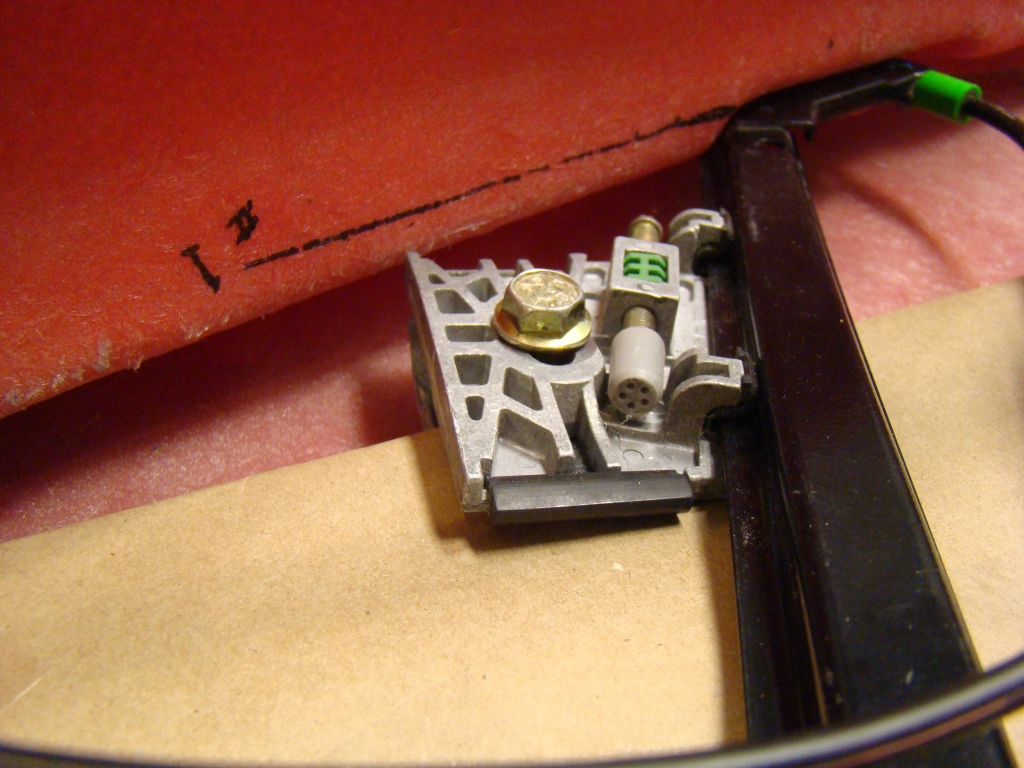

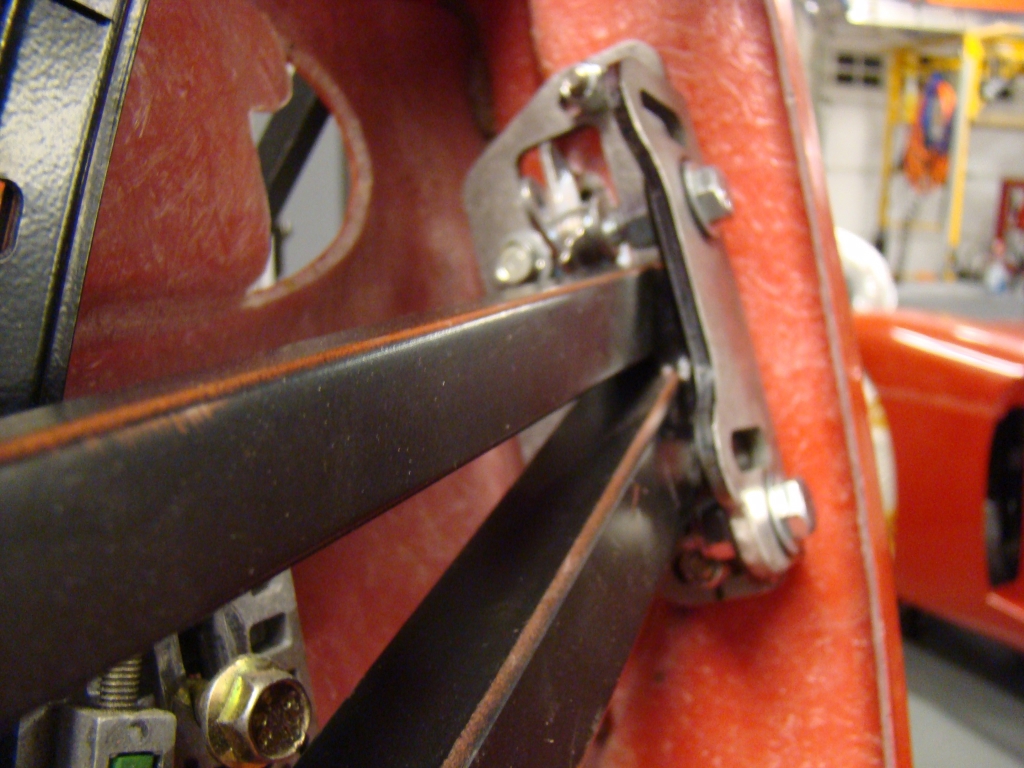

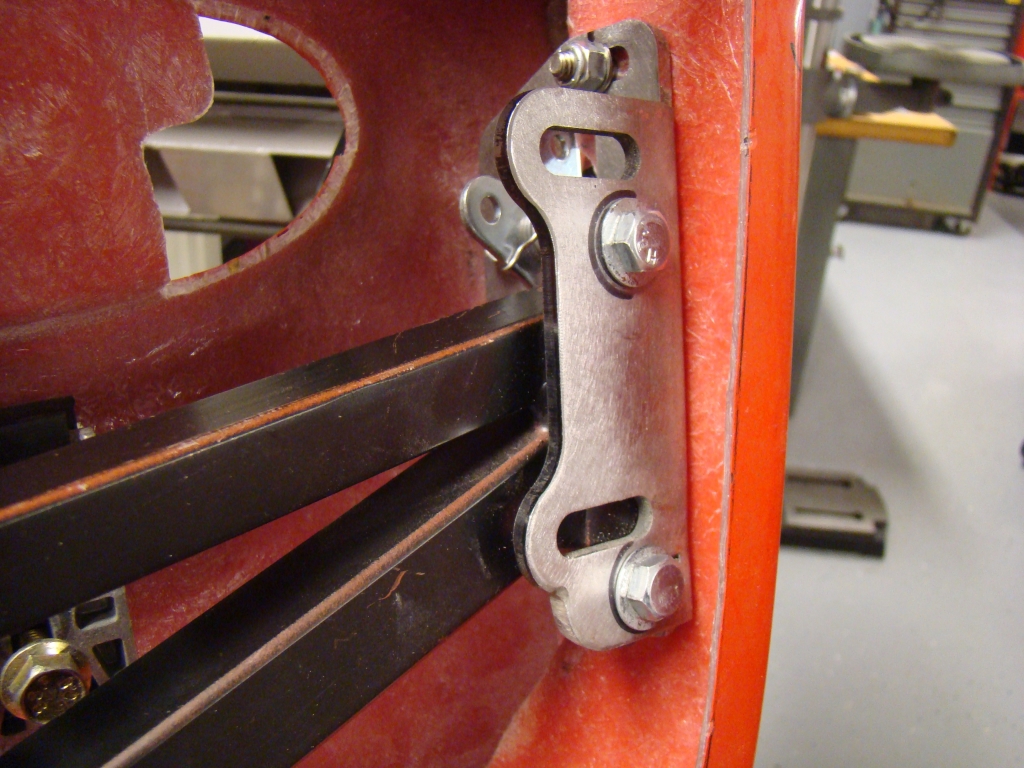

NOT THAT YOU NEED TO BUT THE FIRST THING I NOTICED WAS THAT THE

SLOTTED HOLES SAT TO HIGH CAUSING A PRELOAD ON THE FRAME.

BEFORE ACTUALLY WELDING THE END OF THE FRAME, I ADDED AN 'EAR' TO

THE BRACKET LOWER EDGE AND SIMPLY REDRILLED THE BRACKET.

PRETTY EASY MOD IF THE HOLES AREN'T WHERE YOU NEED THEM. ILL

JUST LEAVE THE OTHERS IN CASE....AND SO THE END RESULT LOOKS

SOMEWHAT THE SAME ON THE OTHER SIDE. DONT REALLY CARE BUT I

DON'T WANT DRASTICALLY DIFFERENT CONFIGURATIONS FROM LEFT TO

RIGHT.

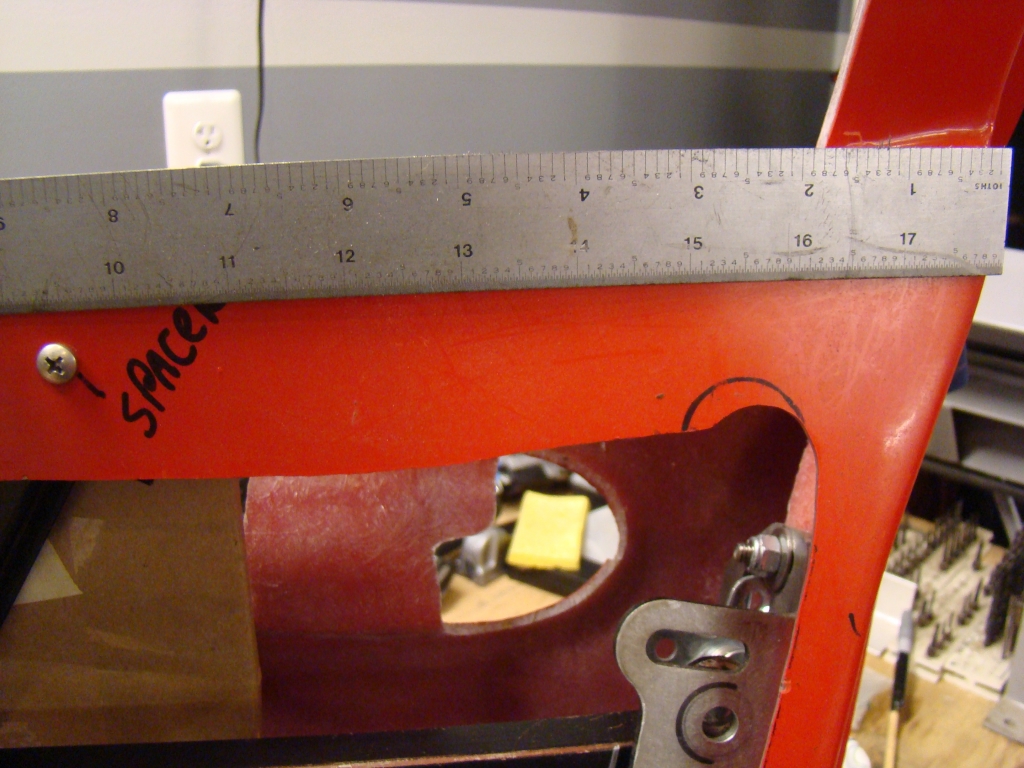

NOTE MEASUREMENTS ARE DIFFERENT THAN WHAT FACTORY FIVE

SAYS. THEIR PICTURES ARE TERRIBLE AND THEY DON'T SPECIFY THE

"EDGE" OF THE DOOR VERY WELL.

SAME REFERENCE IDEA AND ISSUES UP FRONT

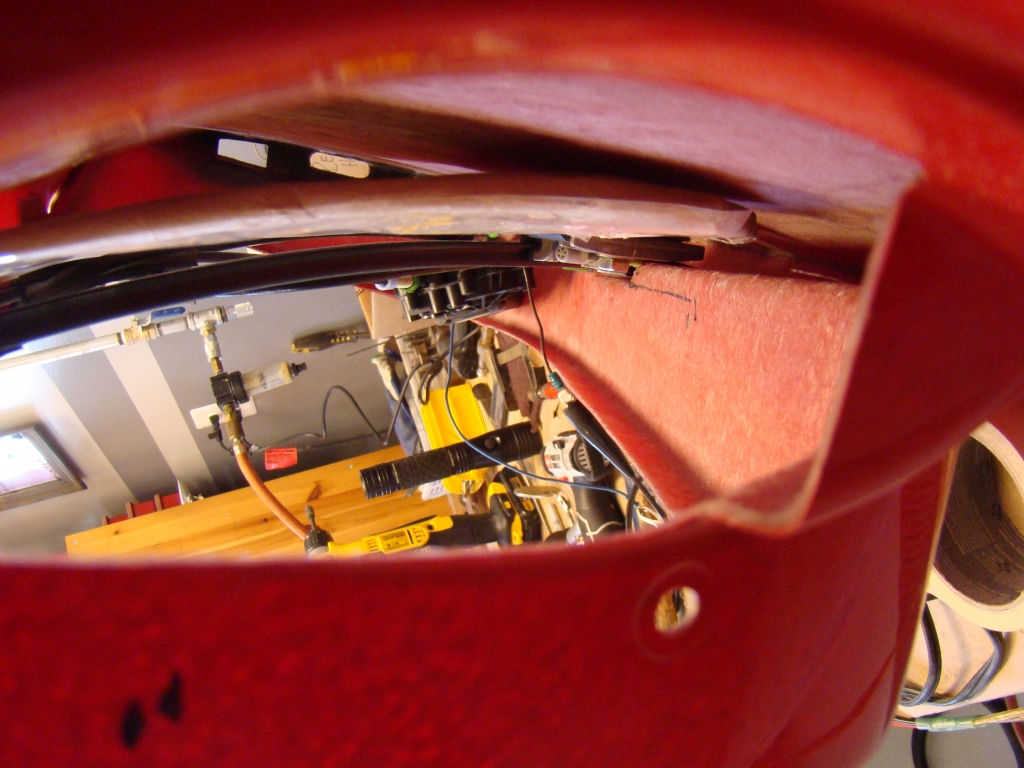

NOTE WINDOW PROTRUSION AFTER ADJUSTMENTS TO ALL THE LITTLE

AREAS. WITH A SEAL IN PLACE THE WINDOW WILL ALMOST BE HIDDEN

FROM VIEW.

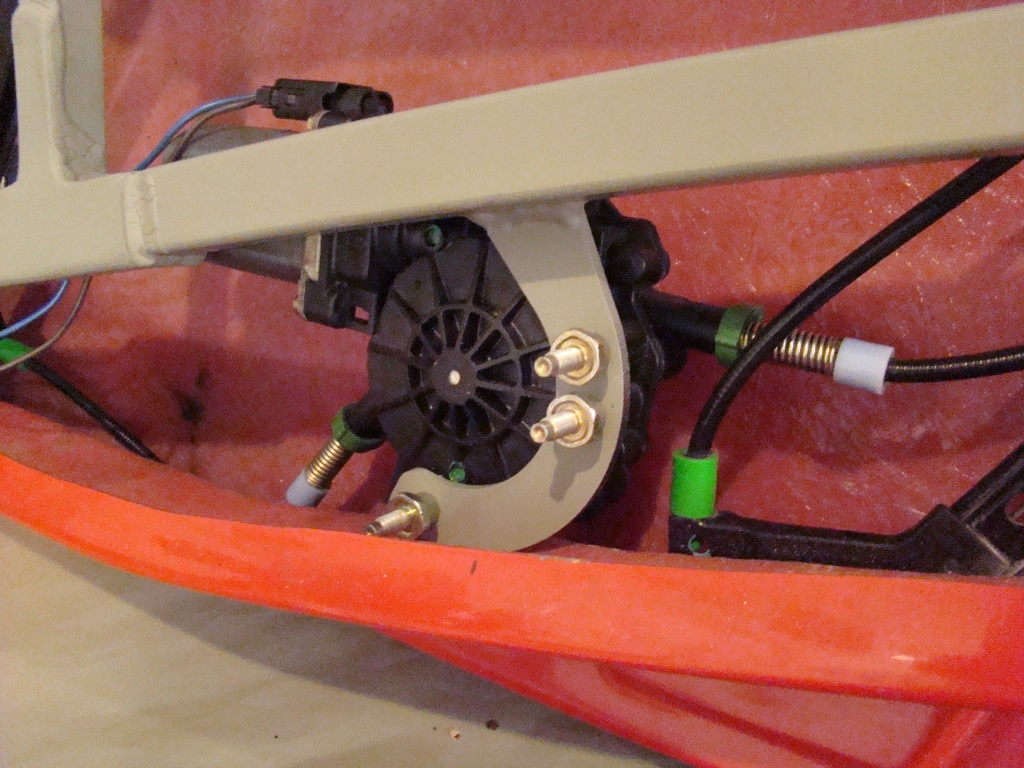

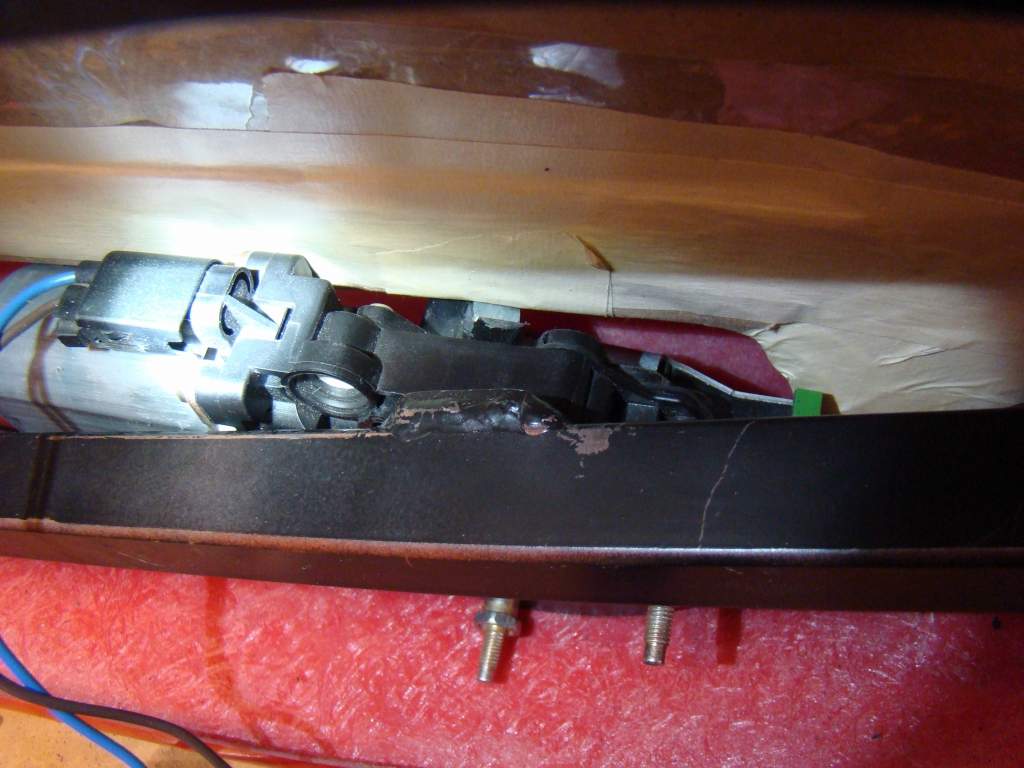

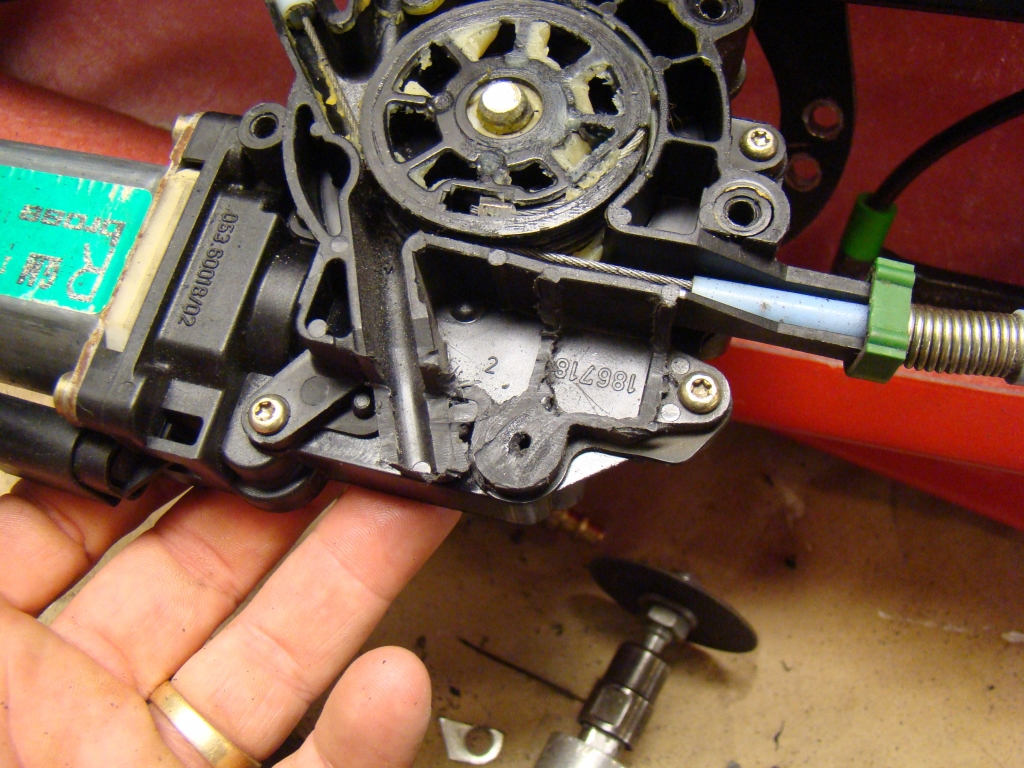

IM CERTAIN ALL DOORS WILL CONTACT THE TOP OF THE MOTOR.

THIS SHOWS WHAT THE MODIFICATION TO THE MOTOR HOUSING WILL DO FOR

YOU

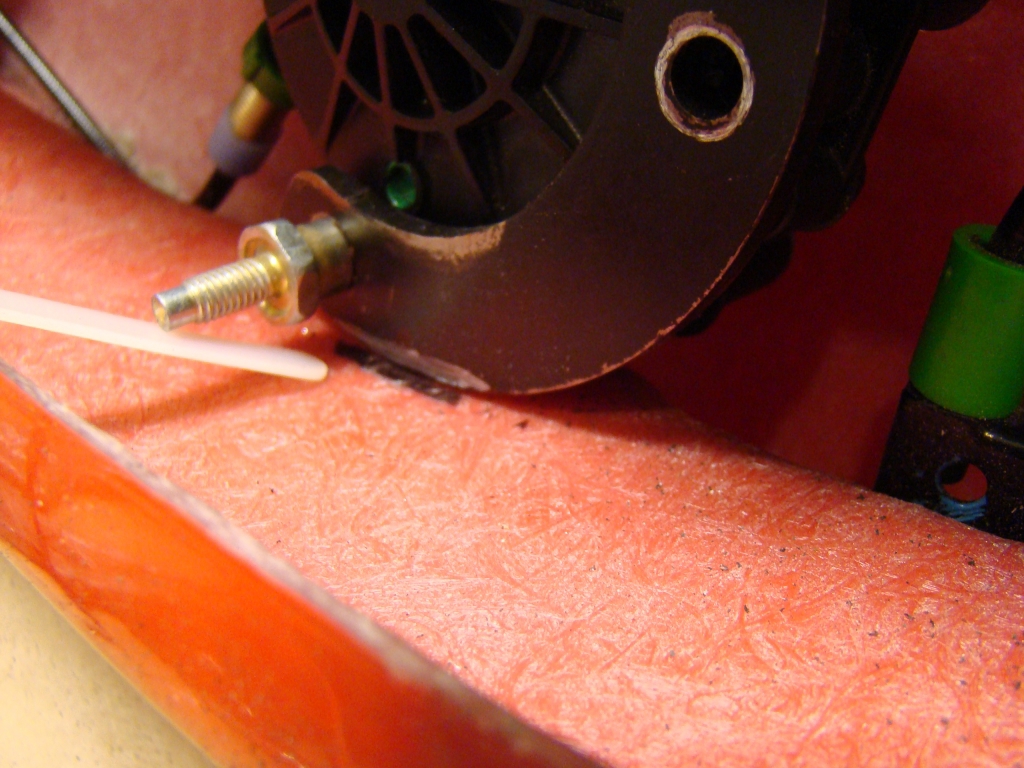

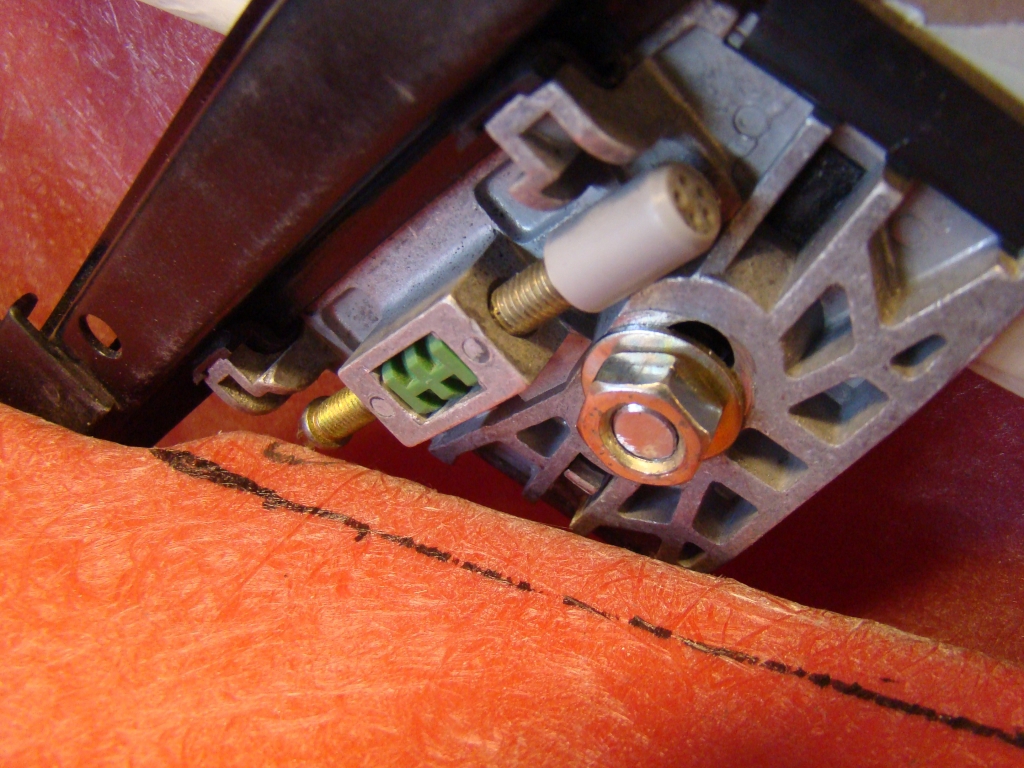

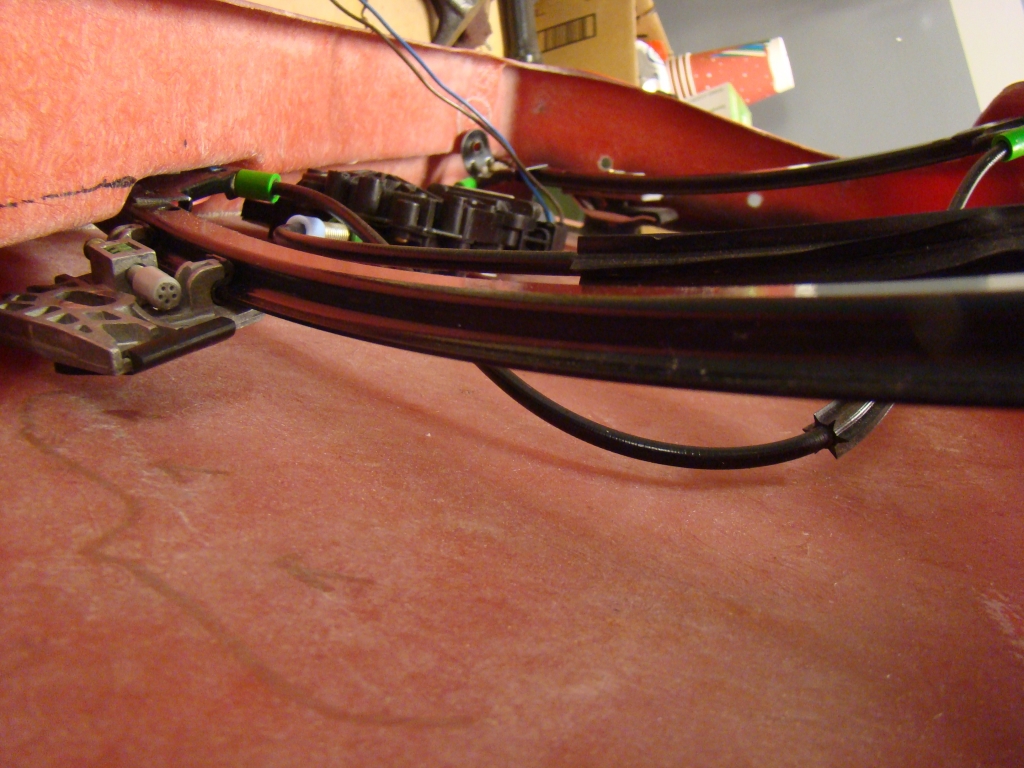

ENSURE YOUR WINDOW DOESN'T HIT THE BOLT AND NOT AT THE FWD

HINGE. THIS IS REALLY A MATTER OF HAVING THE WINDOW SLID BACK IN

THE TRACK. NOT MORE.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

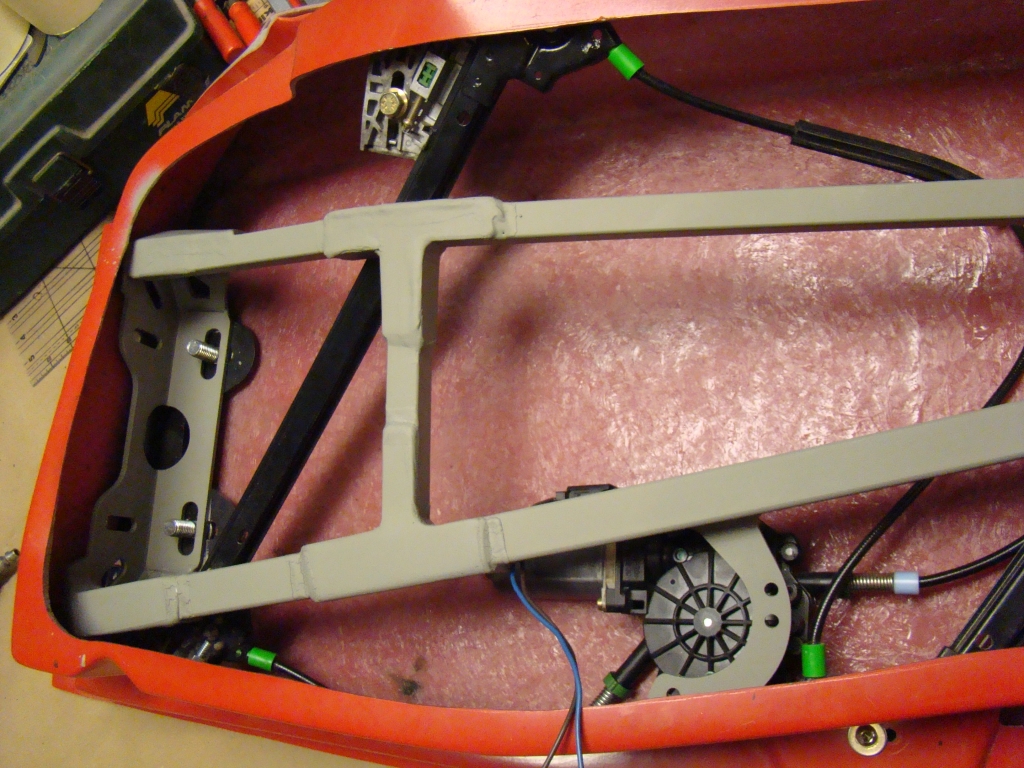

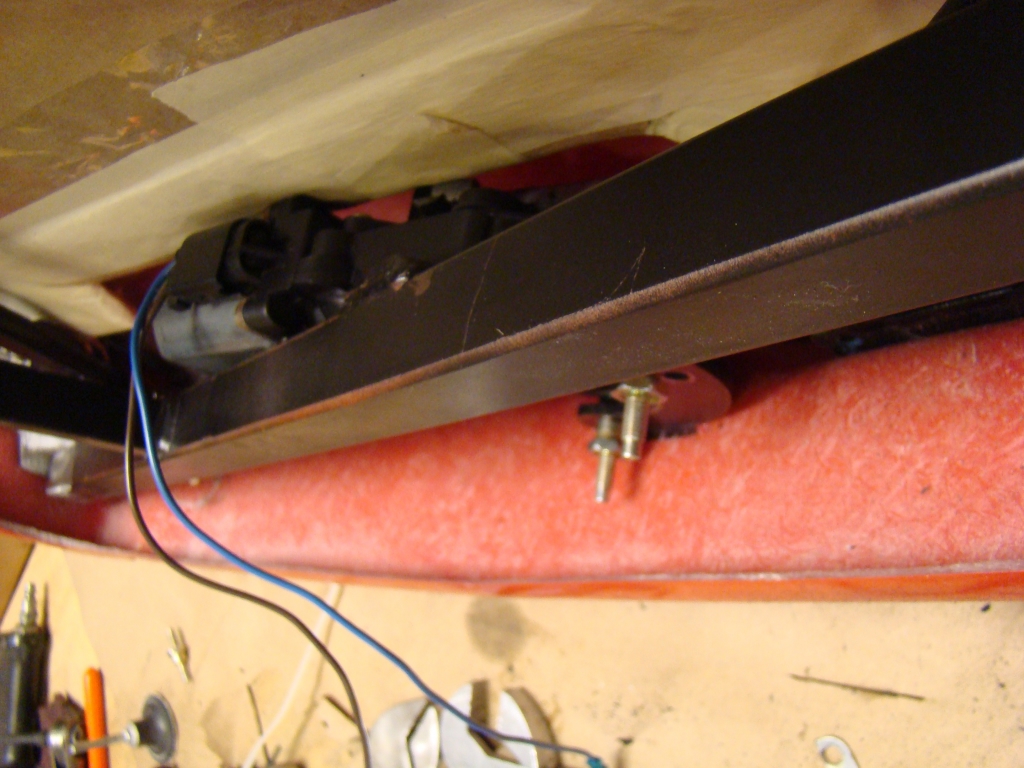

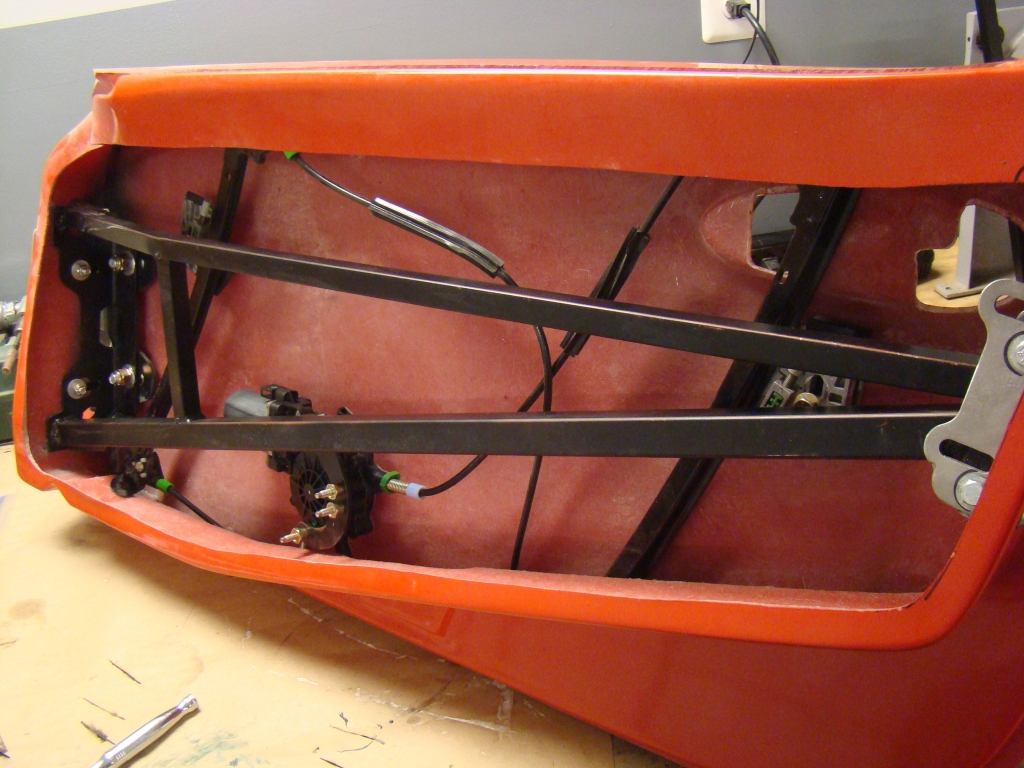

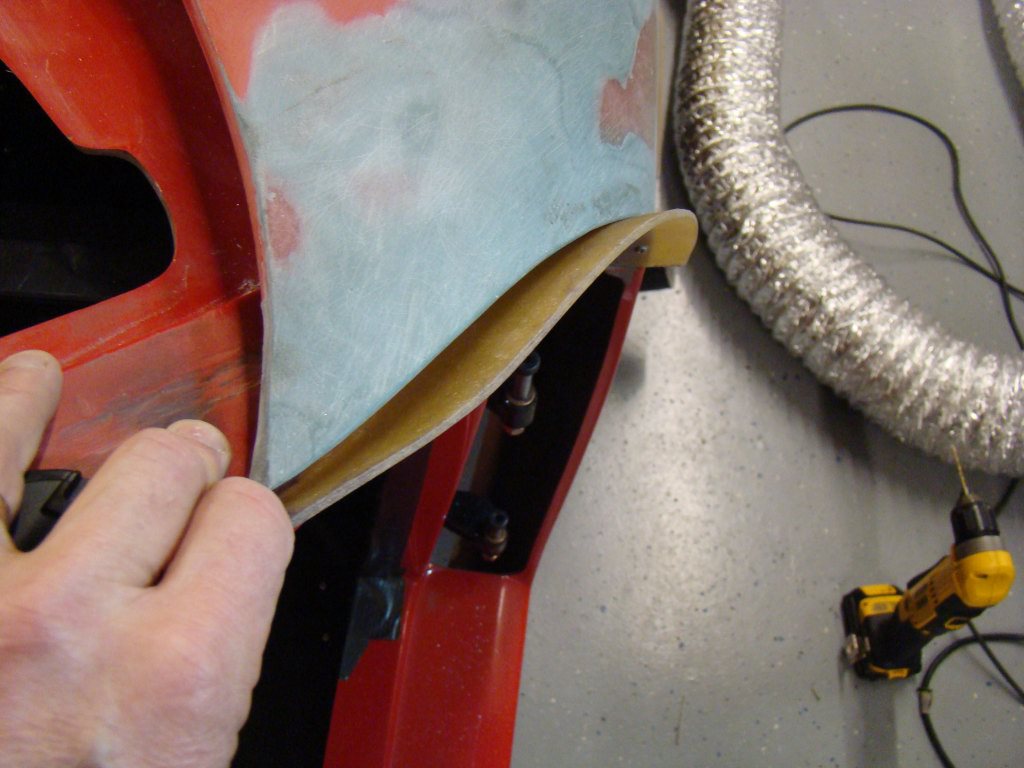

NOTE THAT WITH THE WINDOW TRACKS IN AND WINDOW MOUNTED AND

TESTED, THE FRAME IS SLOTTED AND BENT INTO POSITION. METAL

MUST BE FABRICATED TO BRIDGE THE FRAME TO THE HINGE WELDMENT AND

THEN TACK WELDED IN PLACE. REMEMBER, THE DOOR HAD BEEN FITTED

WITHOUT THE WINDOW SO THE FWD AND AFT HINGE AND LATCH HAD ALREADY

BEEN LOCATED. BY TRACING THE BOLTS, WASHERS AND TRANSITIONS OF

EACH, YOU CAN BOLT THESE BACK INTO POSITION EVEN WHEN THE FRAME IS

IN PIECES. THEN YOU SIMPLY RE-WELD THE FRAME MEMBER AND THE

SLOT YOU CUT TO CHANGE THE ANGLES. THESE SLOTS AND THE ANGLE

DIFFERENCES ARE WHAT ALLOW CLEARANCE OF THE TRACKS AND GET THE

FRAME POSITION TO NOT PRE-LOAD THE FIBERGLASS AT THE FRONT AND

BACK. NOTE THE PROXIMITY OF THE WINDOW CLAMP BOLT HEAD!!!

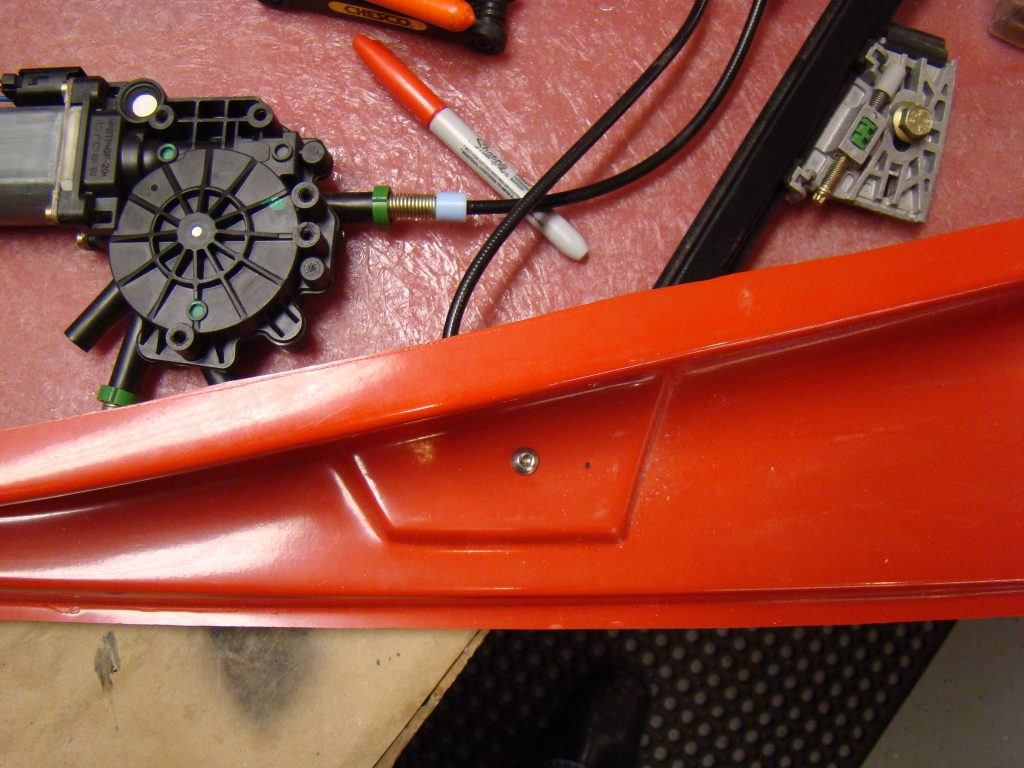

MOTOR NOW UP AGAINST THE FRAME AS CLOSE AS I COULD GET

IT.

THIS CUTOUT AND THE PROTRUSION REMAINS CONSISTENT AND AT THE

SAME PLAIN (NO GREATER) THAN THAT AHEAD OF IT FOR THE WINDOW TRACK.

THIS MEANS YOU HAVE ROOM AND IT WILL NOT HIT THE LOWER DOOR FRAME

MEMBER AND FIBERGLASS ON THE CHASSIS. THIS BUYS ABOUT 1-1/2-2" OF

TRAVEL. TO DO THIS, YOU MUST USE 1/4-3/8 SPACERS AT THE UPPER TRACK

MOUNT POINT TO ESSENTIALLY GET THE TRACK CONTOUR PARRALLEL (MORE

ANYWAY) TO THE DOOR SKIN.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

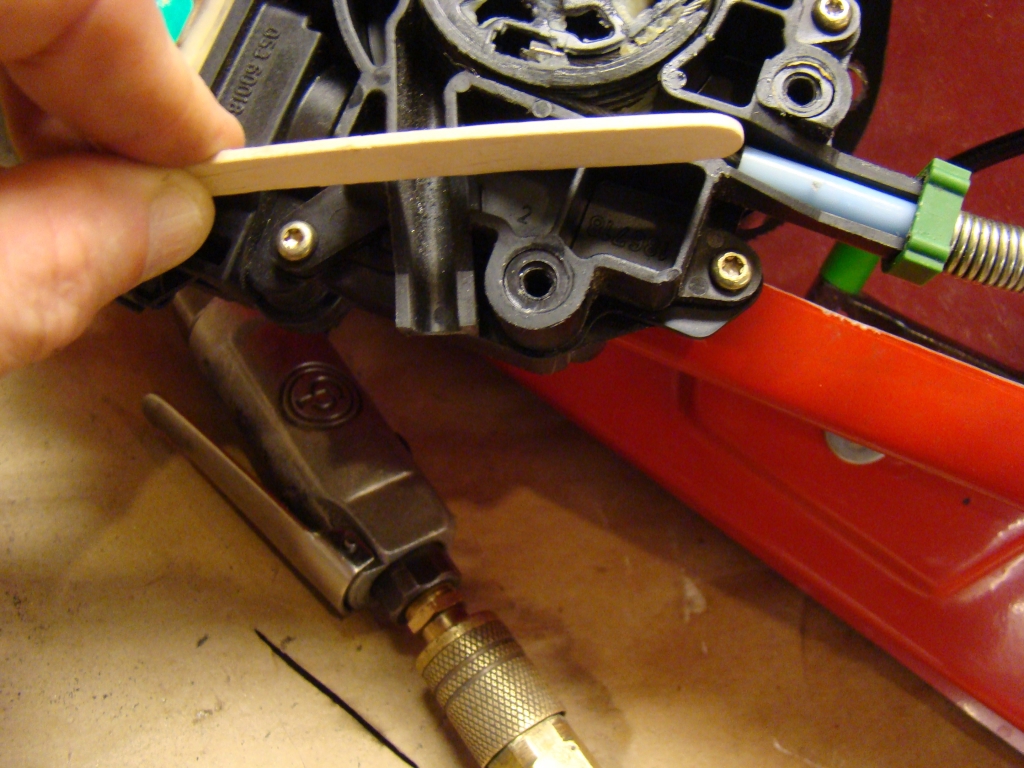

NOTE THAT AFTER THE CUTOUT IS MADE IN THE HOUSING, THE ENDS OF

THE COVER ARE BENT OVER AND THEN SEALED.

POPSICLE STICK SHOWS AREA REMOVED BUT ONLY AT THE DEPTH OF THE

'TUB' IN THE BODY. DON'T CUT THE ENTIRE CORNER OFF.

MAJOR REWORK IS NECESSARY. CUT THE WELDMENT FROM THE END

OF THE SQUARE TUBES. BE AS CAREFUL AS POSSIBLE AND SACRIFICE THE

WELDMENT MORE THAN THE TUBES. IN OTHER WORDS, IF YOU NICK

SOMETHING, NICK THE THICK WELDMENT. THIS WILL LESSEN THE

EXTENT TO WHICH THE REPAIR AND WELDING IS NEEDED WHEN YOU

REASSEMBLE LATER. A SAWZALL WORKS GREAT.

NOTE THE EXTENT TO WHICH THIS CUT IS MADE. ITS POSSIBLE TO

CAPTURE THIS AREA IN THE TOTAL RECESS THAT INCLUDES THE LOWER

TRACK. LATER, THIS WILL BE GLASSED AND SIMPLY CHANGE THE

OVERALL DIMENSION (BUT NOT DEPTH) OF THE AREA THAT RIDES AGAINST

THE LOWER DOOR FRAME AND GLASS ON THE CAR.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

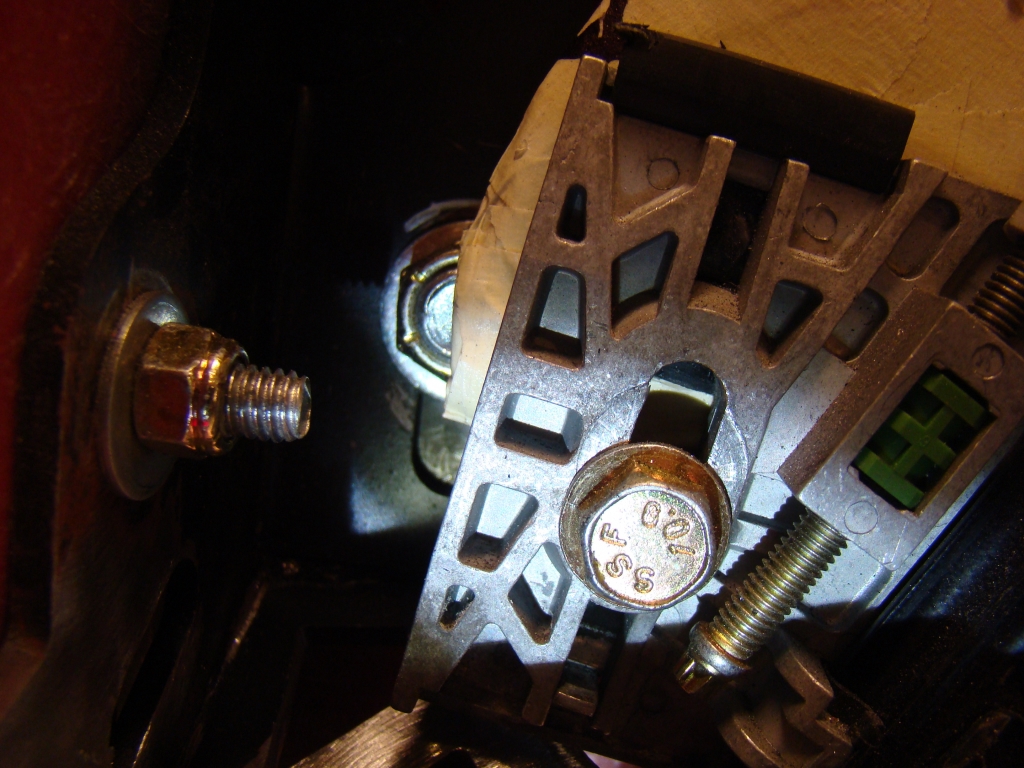

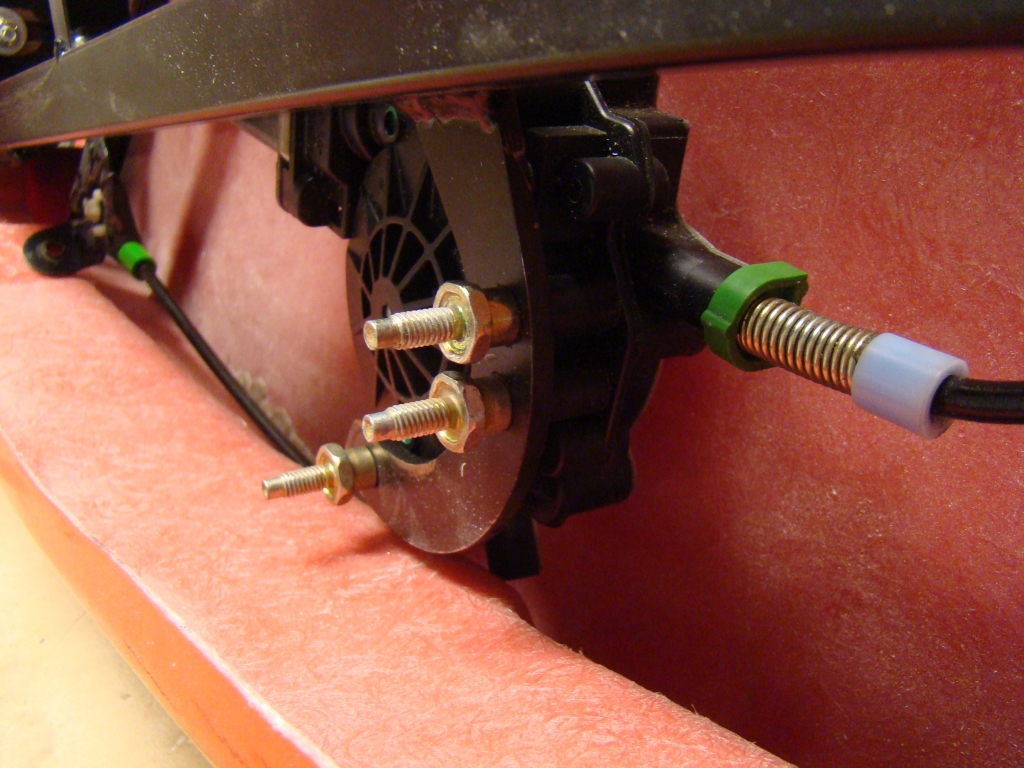

THE INFAMOUS GLASS AND SKIN CONTACT AREA. SPACERS ON THE

UPPER WINDOW TRACKS CHANGE THE PLAIN THE WINDOW TRAVELS IN AND

LESSENS THE CONTACT. ALSO, USING STUDS INSTEAD OF THE BOLTS

IN THE WINDOW CLAMPS AT THE AFT EDGE, PREVENT CONTACT.

STUDS CAN BE MADE FROM MANY MATERIALS INCLUDING THESE "SLOAN"

URINAL MOUNT STUDS THAT ARE NICELY CADMIUM PLATED.

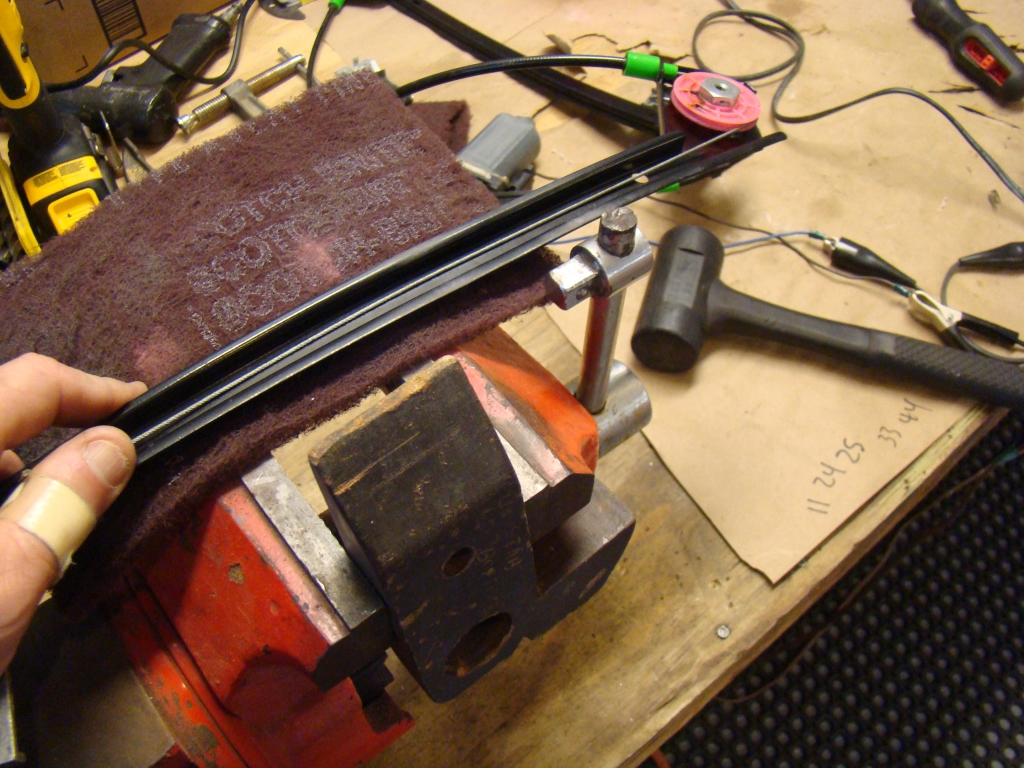

FORMING THE AFT FRAME. ACTUALLY, USING A FORMING BLOCK AND

TAPING THE TRACK ON THE OUTSIDE OF THE BOW, YOU CAN "SHRINK" THE

GRANULAR STRUCTURE WITHOUT CUTTING OR HEATING. THE TRACKS DO

NOT NEED TO BE "TORCHED" TO DO THIS. EVEN IF HOT, THE SAME

KINKS WOULD OCCUR THAT YOU EXPERIENCE UNDER A MORE EXTREME FORMING

PROCESS. ONLY A MALLET, BUCKING BARS AND PATIENCE ARE NEEDED

TO HAND FORM OR COLD WORK THE TRACK ENOUGH TO GET IT IN THE RIGHT

PLAIN.

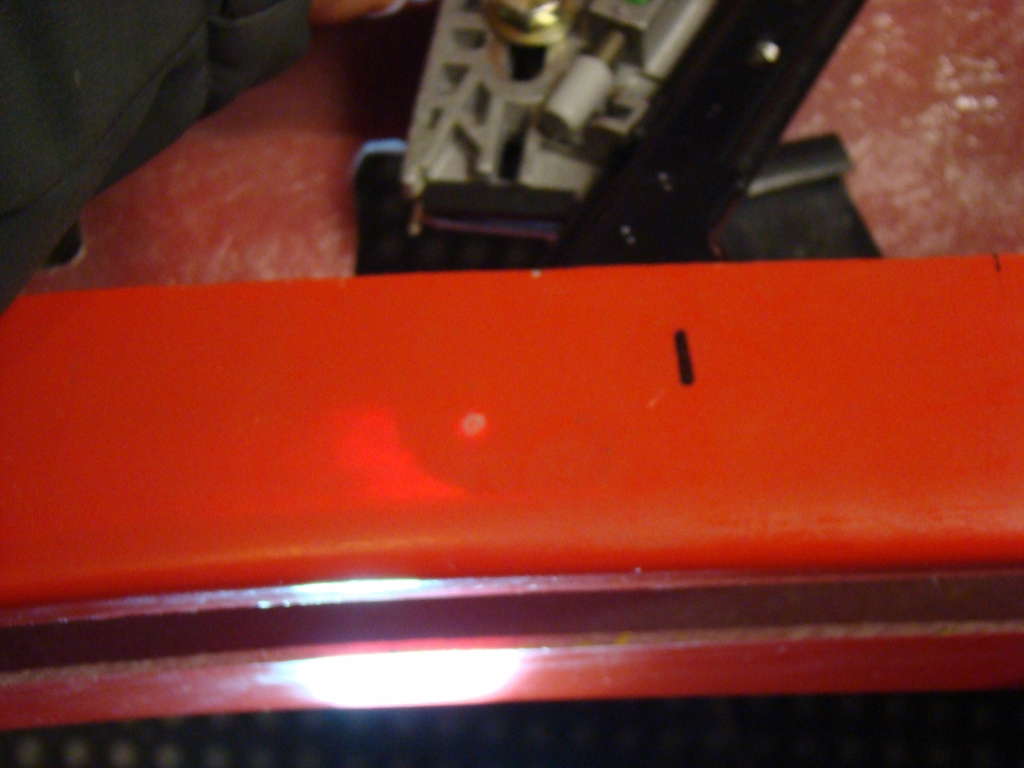

NOTE THE SILVER/WHITEISH MARKS ON THE DOOR SKIN. THOSE ARE

SCRAPES FROM THE WINDOW CLAMP MOUNT BOLT HEAD.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

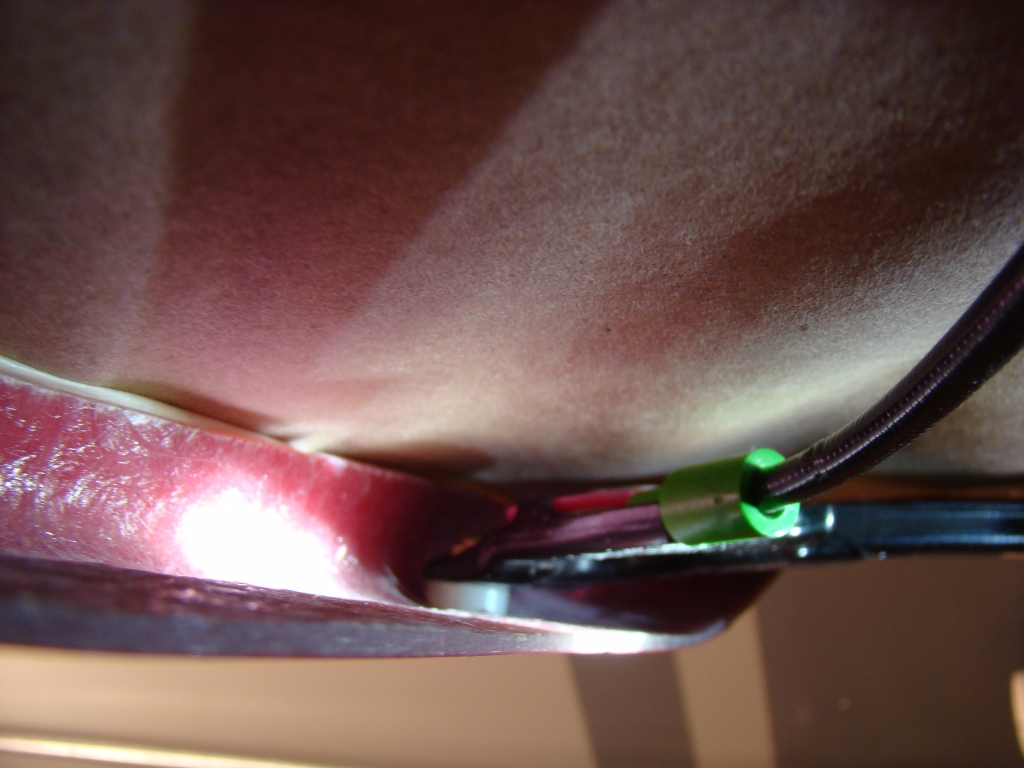

VERY IMPORTAND SPACERS MADE OF NYLON AT THE UPPER TRACK MOUNT

POINTS. TRY THEM. THEY HELP POSITION EVERYTHING IN THE

RIGHT PLAIN AND GET THE WINDOW TO COME UP THROUGH THE OPENINGS AND

ALONG THE AFT VERTICAL CHANNEL ON THE DOOR FIBERGLASS.

NOTE THAT THE ABOVE PICTURES SHOW LIGHT BEING USED WITH A MIRROR

TO LOCATE THE HOLES THAT NEED TO BE DRILLED FOR THE TRACKS.

USE THE LIGHT AND A MIRROR TO PROJECT LIGHT THROUGH THE GLASS AND

THEN MARK IT. YOU MADE NEED TO TURN THE LIGHTS IN THE GARAGE

DOWN AND MAKE SURE YOUR BATTERIES ARE CHARGED.

THE BOLT RUBBING THE SKIN

COLD WORKING THE TAB ON THE FWD TRACK. MINOR ADJUSTMENTS

USING FLANGING PLIARS.

I am a text block. Click on me to drag me around or click a corner handle to resize me. Click the settings icon (it's the left one, looks like a cog) to change this text. You can type new text into me or cut and paste text from somewhere else. Click outside of me when you're done and any changes will be saved.

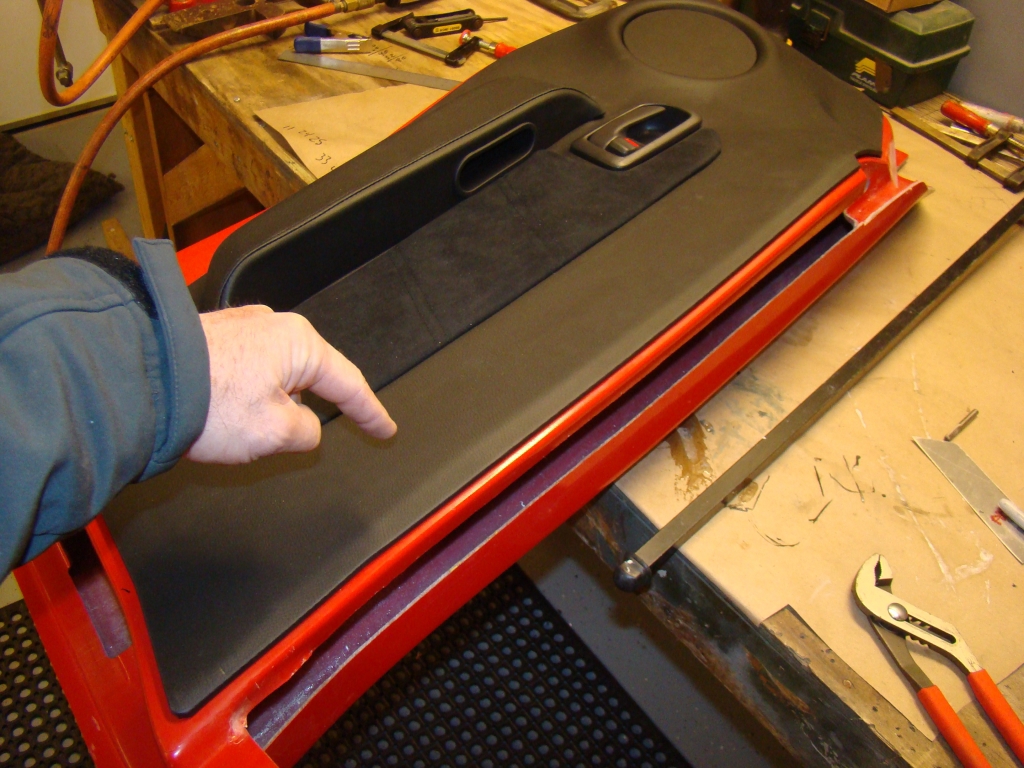

MAKE SURE YOU KNOW WHERE YOUR DOOR HANDLE IS. OTHER THAN THIS

PROTRUSION ON THE DOOR PANEL, THINGS BEHIND THE DOOR PANEL HAVE

PRETTY GOOD CLARANCE FOR FRAME ADJUSTMENTS. JUST DONT MOUNT THE

MOTOR OR DOOR POPPERS HERE.

A NICE WAY TO PROP THE DOOR UP WHILE WORKING.

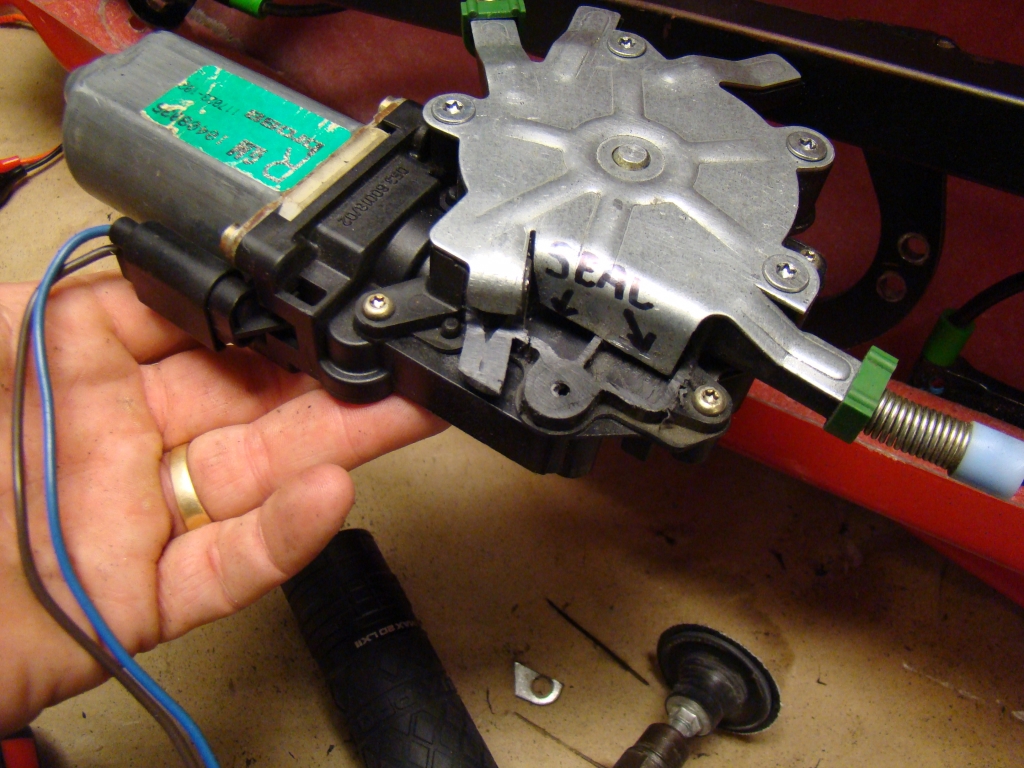

USING THE WINDOW MOTOR MOUNTING BOLTS, MOUNT THE MOTOR TO THE

FRAME.....OR SOMETHING LIKE THAT. THIS IS WHAT FACTORY FIVE

IS TELLING YOU TO DO....ITS THE ONLY WAY UNLESS YOU HAVE SEVERELY

COURSE THREADED HARDWARE. HONESTLY I THINK STEEL HOSE CLAMPS

ARE ADEQUATE OR CAN AT LEAST BE USED IF DESIRED. THE MOTOR

STAYS PRETTY STATIONARY WHEN IN USE. JUST A LITTLE TORQUE

MOVEMENT BUT THE LOAD IS INTERNAL ON THE SPOOL.

ADDED MATERIAL ON THE AFT BRACKET.

THE POCKET FOR THE HOOD LATCH

HAD TO BE CUT TO ALLOW PULLING IT IN SLIGHTLY TO MATCH THE HOOD AND

THE ANGLE/CONTOUR OF THE EFT SIDE IN THE SAME

AREA.

NOTICE THE ADDED GLASS AFT OF THE ORIGINAL FLANGE AT THE

BACK RIGHT SIDE OF THE HOOD