BRAKES

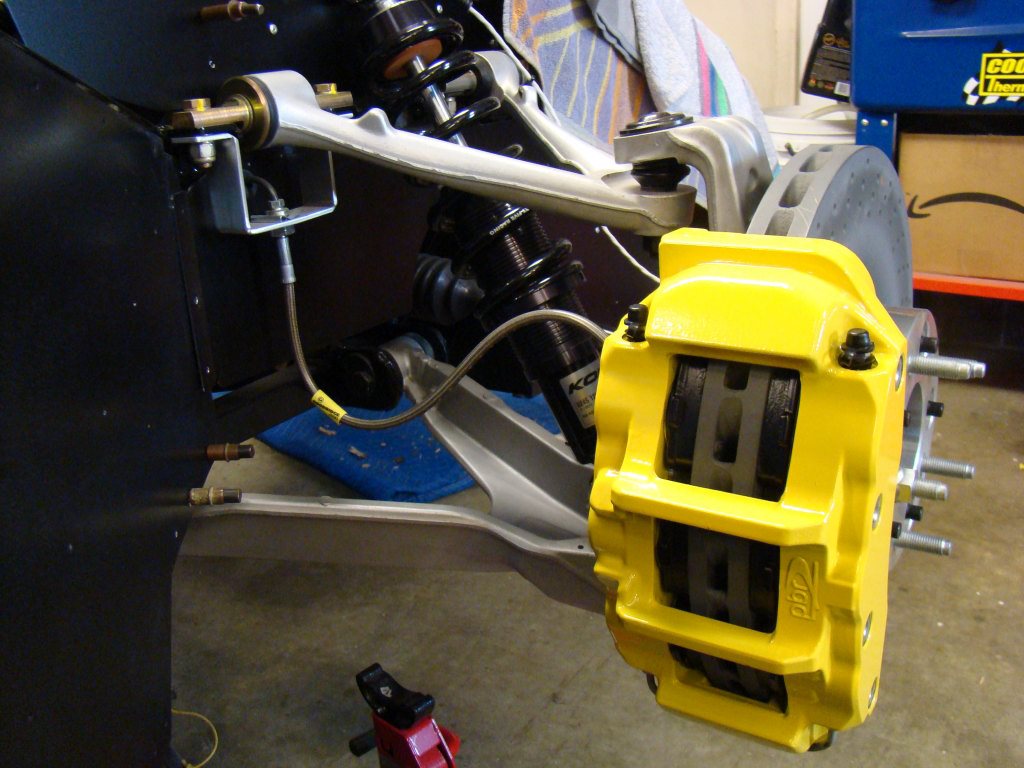

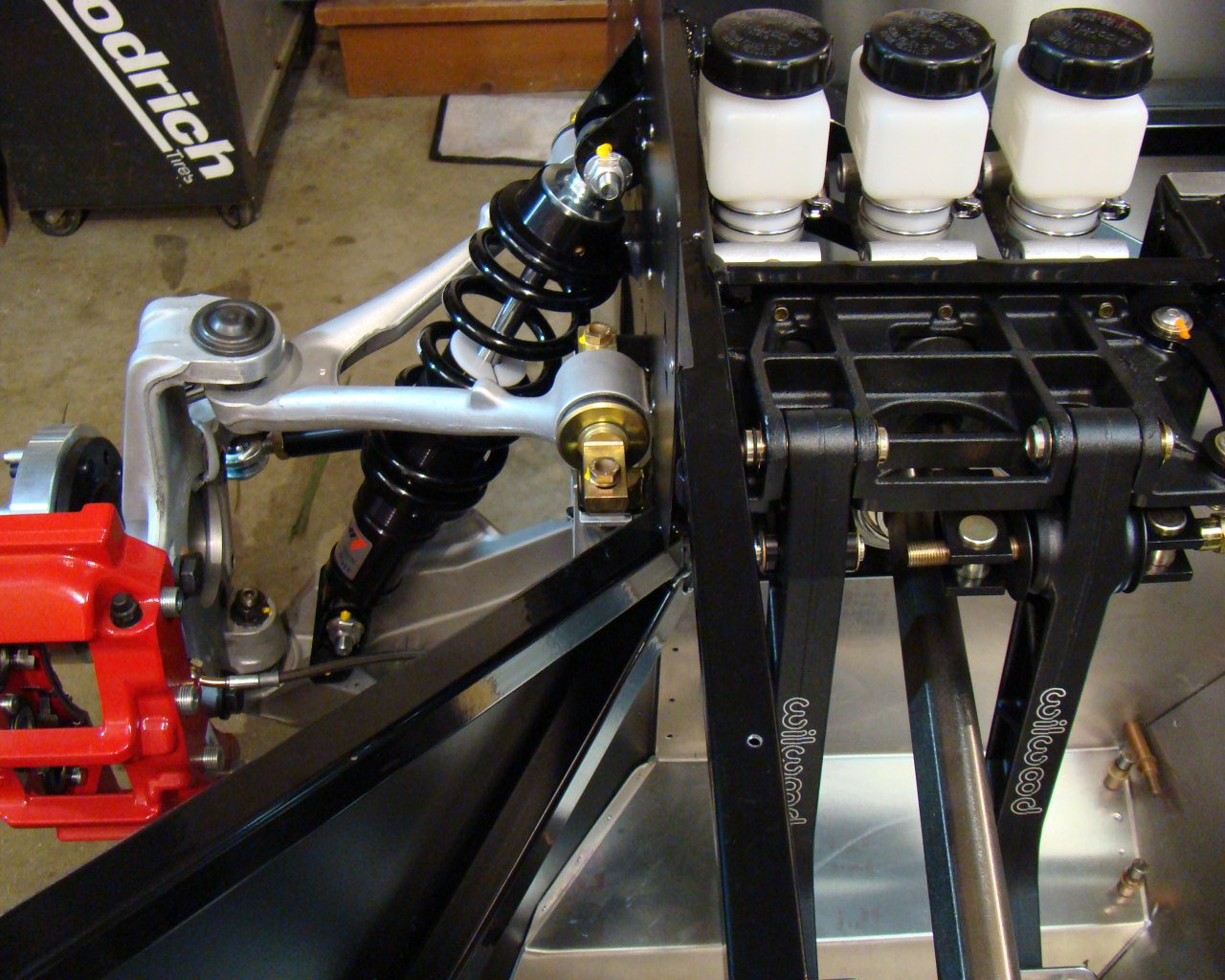

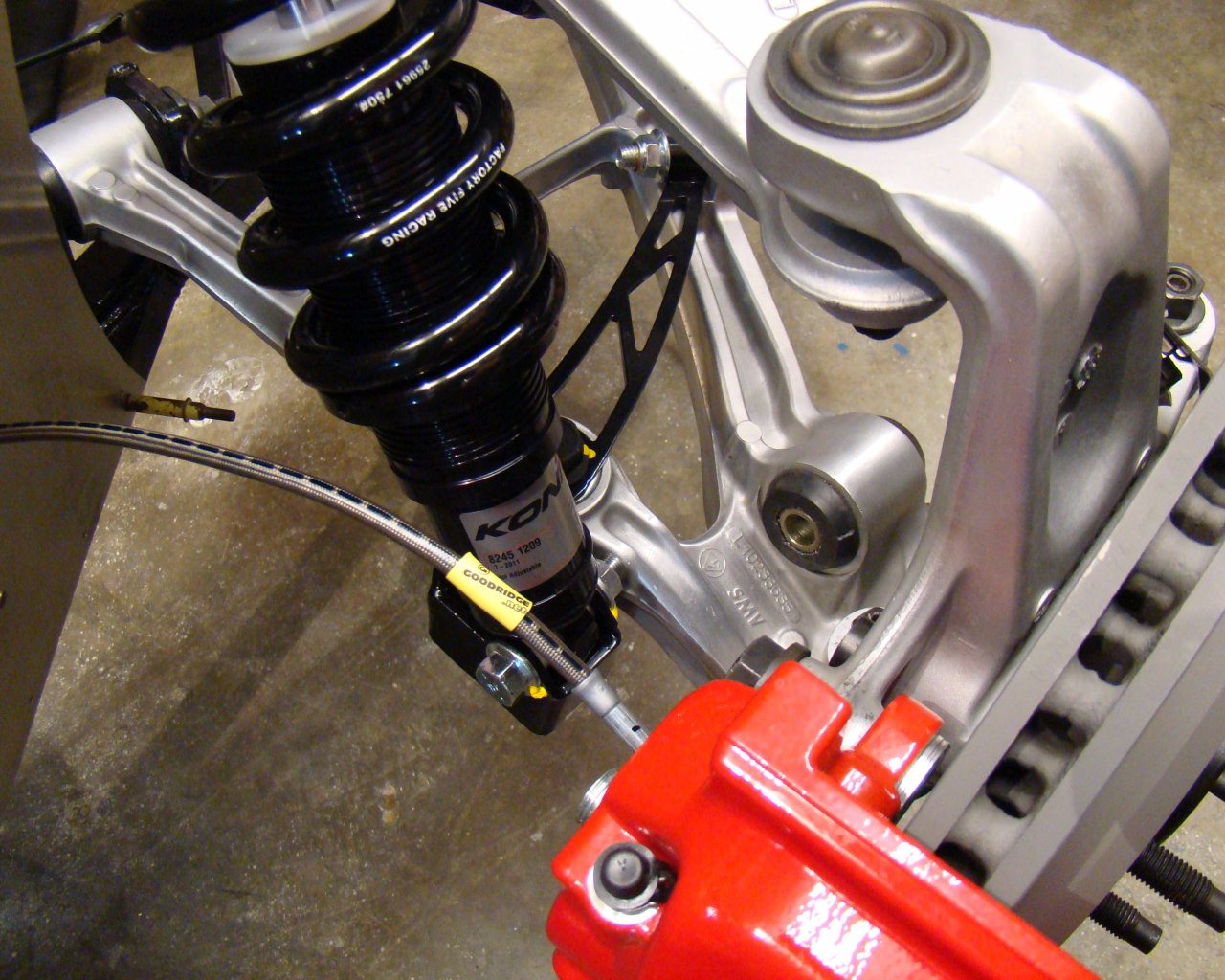

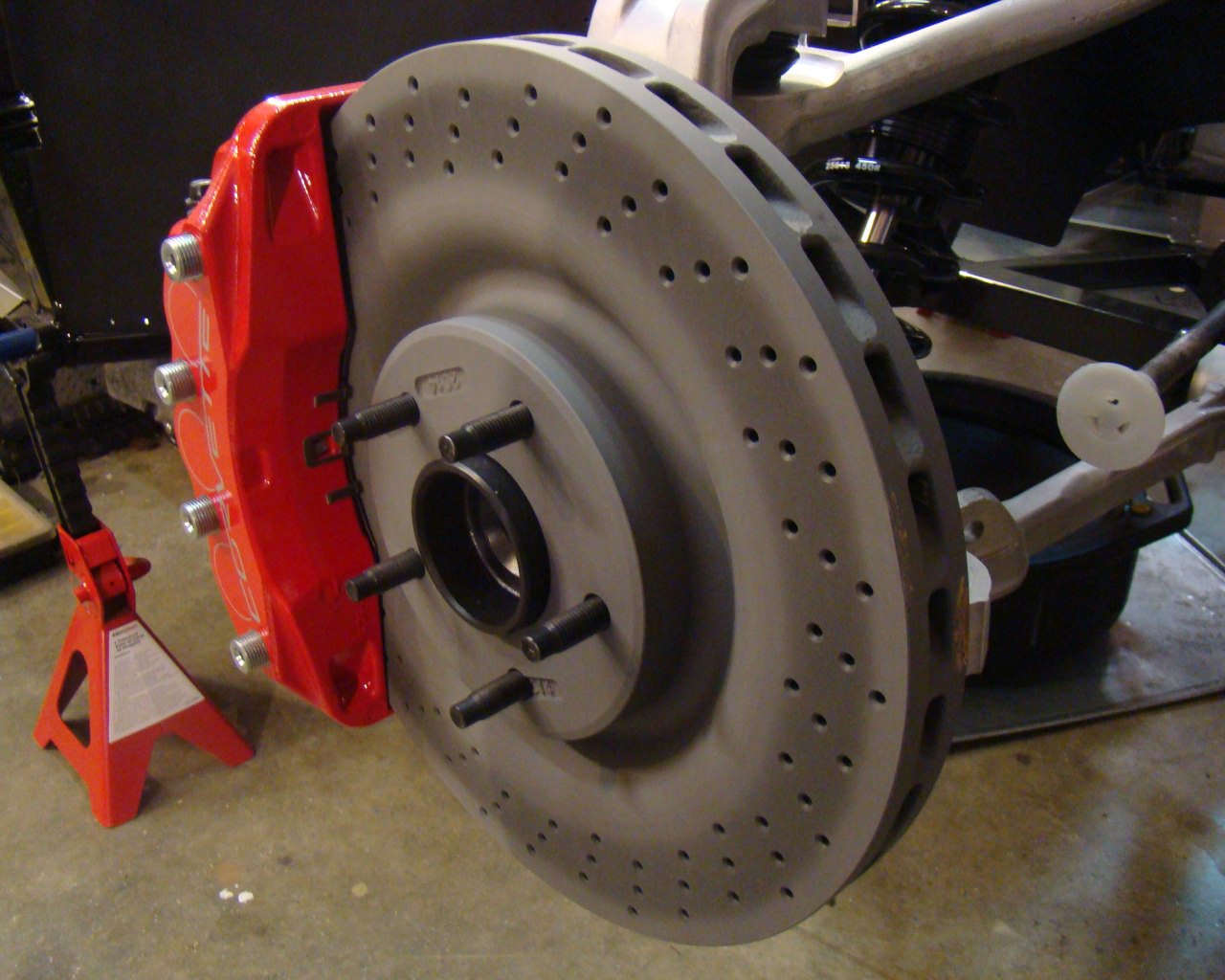

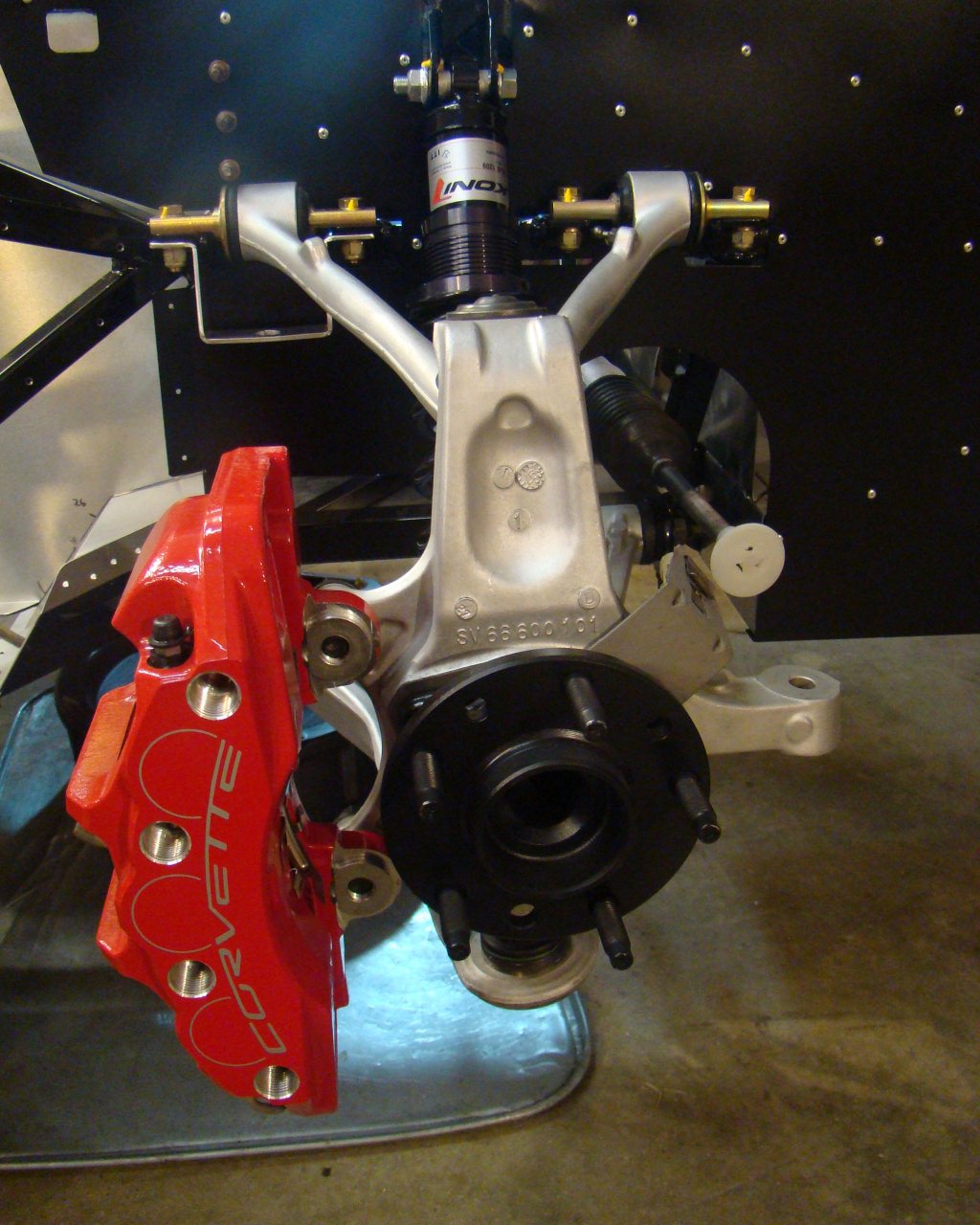

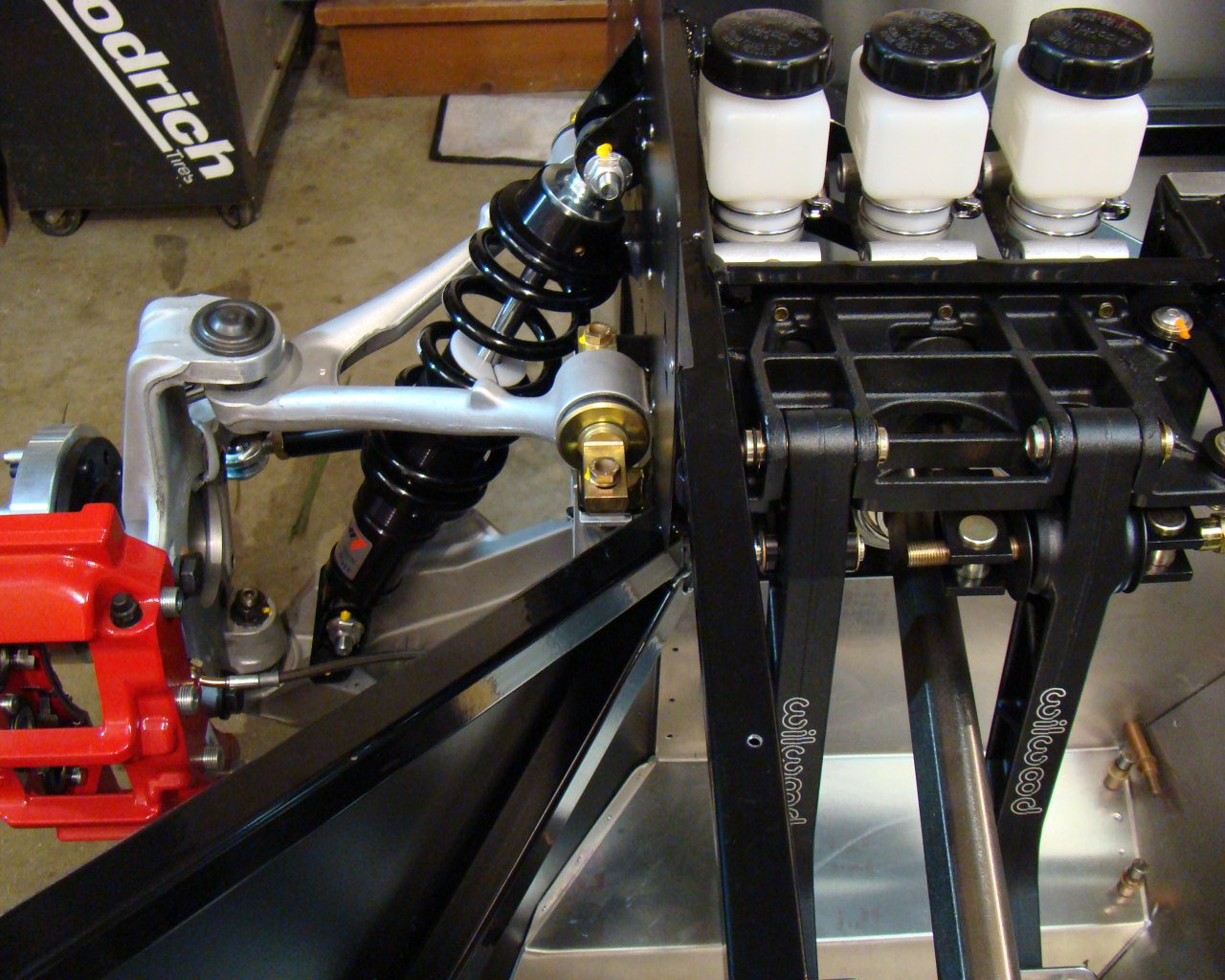

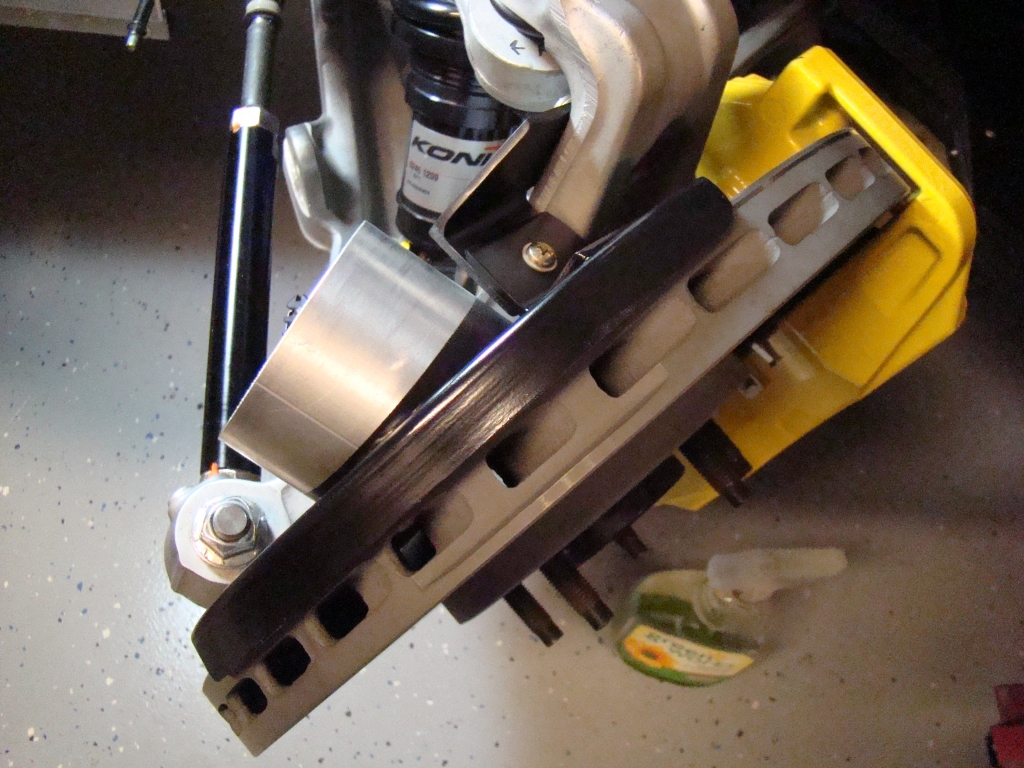

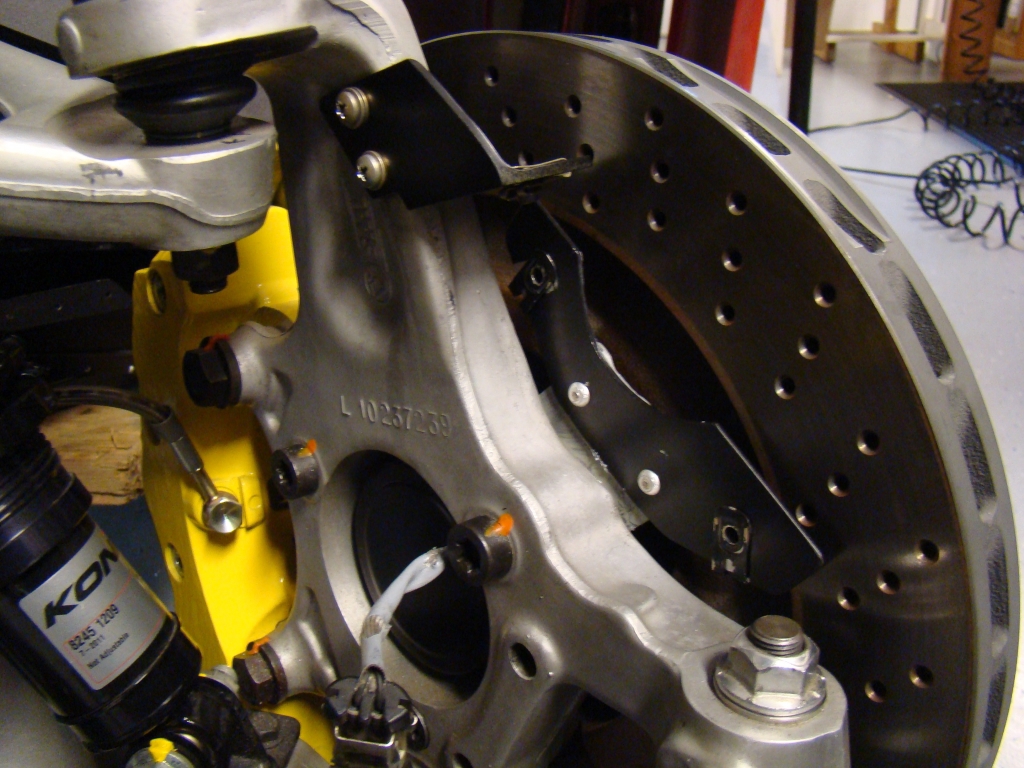

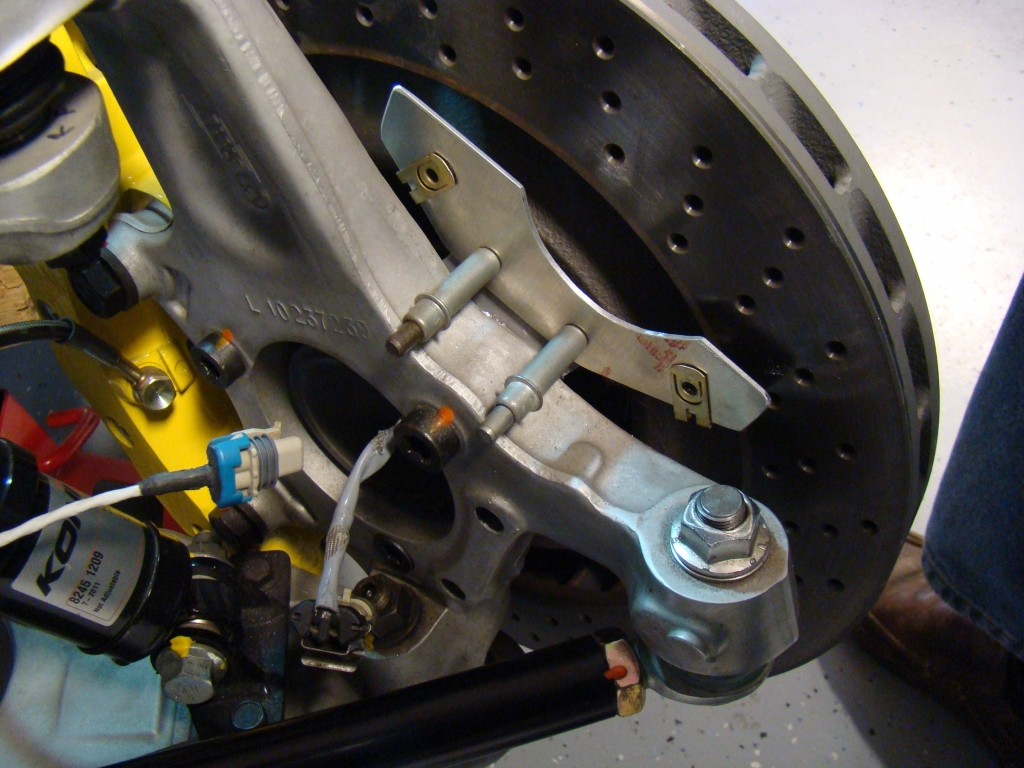

After searching and doing some research on brakes I decided to go with the C6 big brake set. These are what come stock on the Z06 and they are production car proven. I did consider Brembo, Wilwood and Baer but honestly didn't see the need to spend the extra bucks. The Corvette brakes for the Z06 are just as good at stopping the car and there is no guess work involved. The entire package includes 6 piston front, 4 piston rear calipers, 14" rotors and Goodridge brake lines. The only issue I have with the brakes is that the stock GM rotor drilled holes sweep in opposite directions from left to right. This is either a complete oversight or GM decided that production costs mattered more than the difference in performance. They will work, but they are not optimum. I may decide to change them at some point.

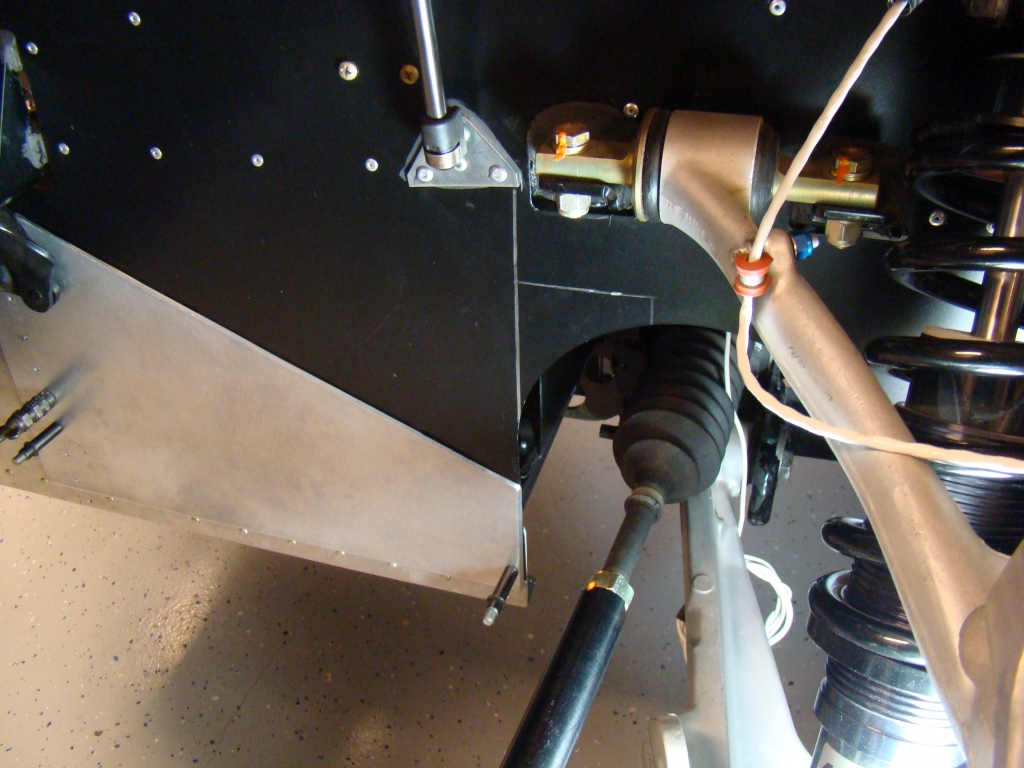

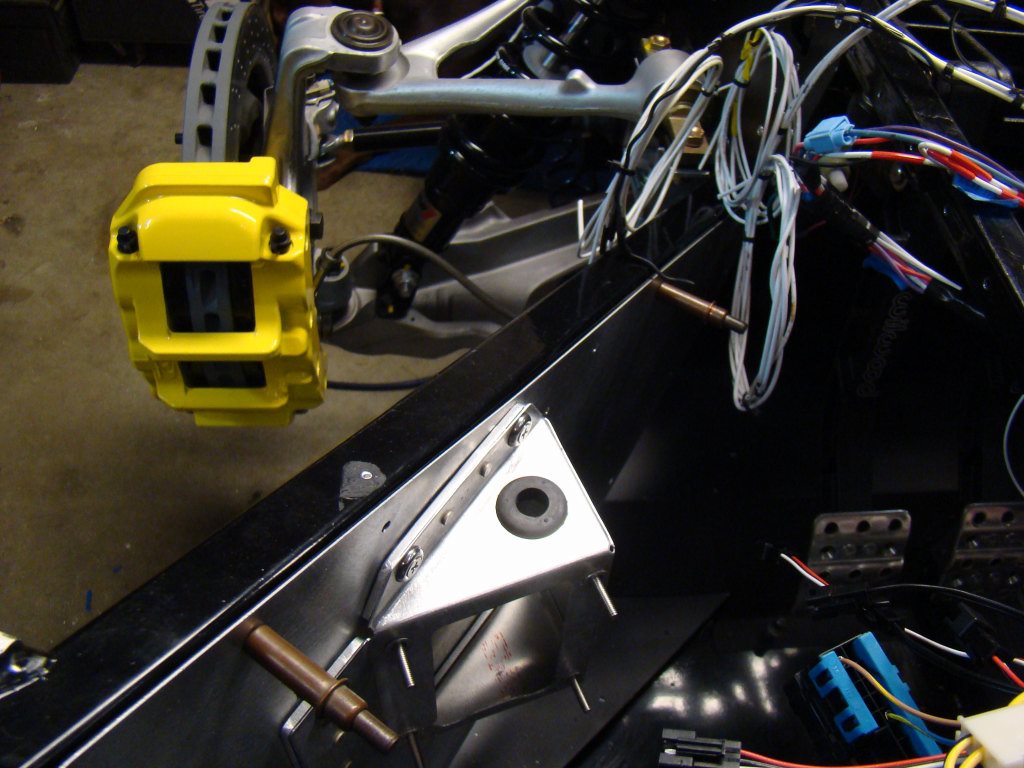

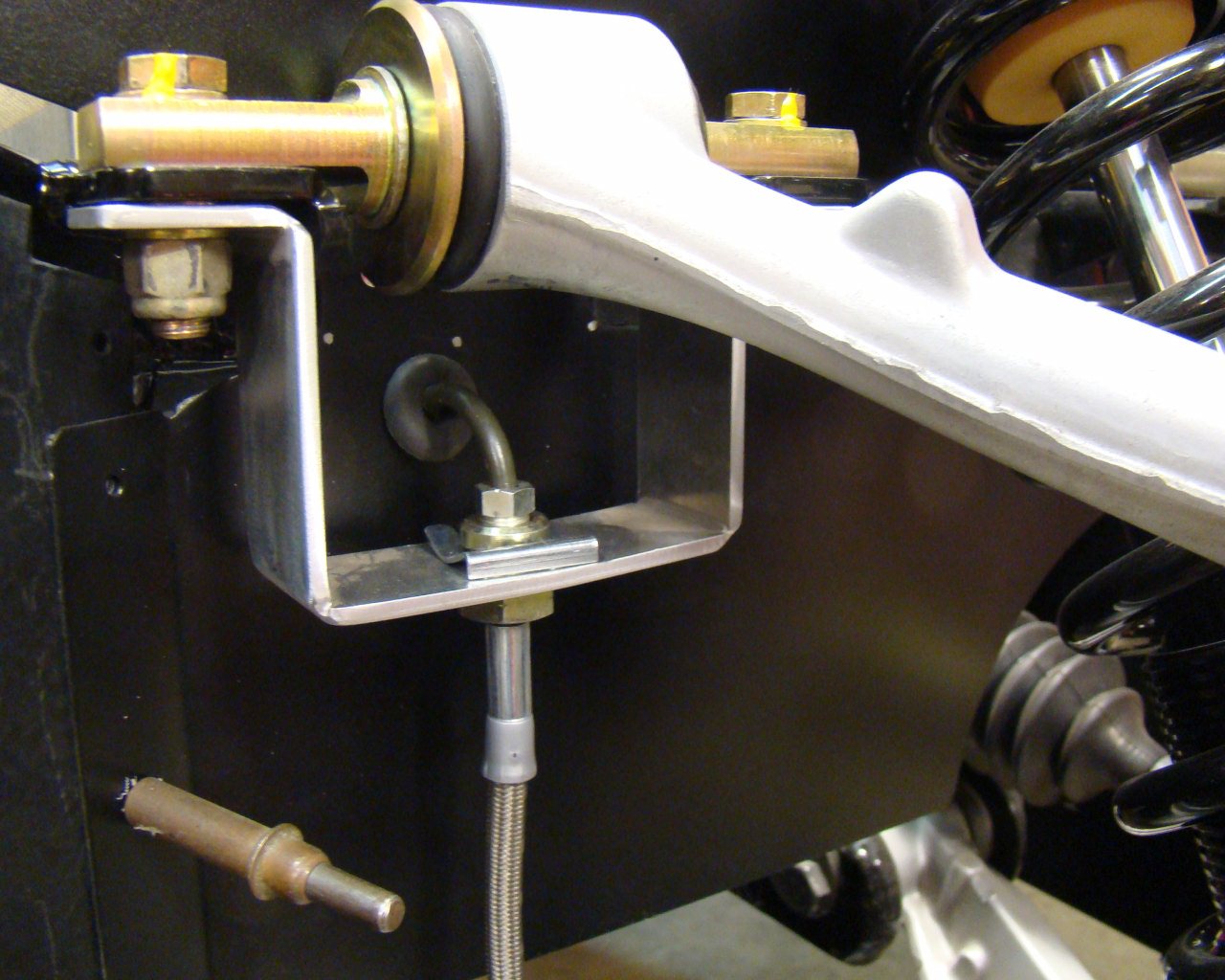

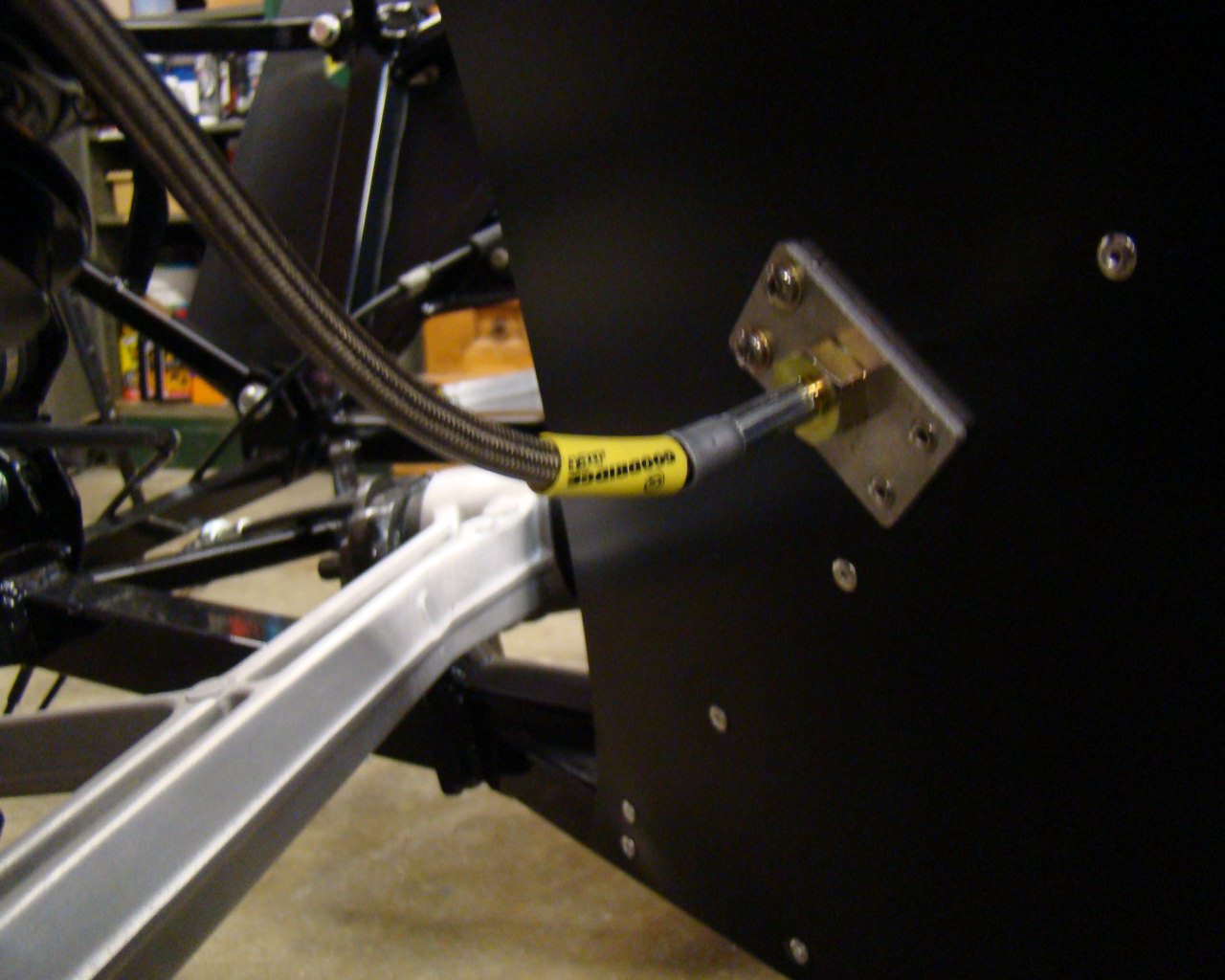

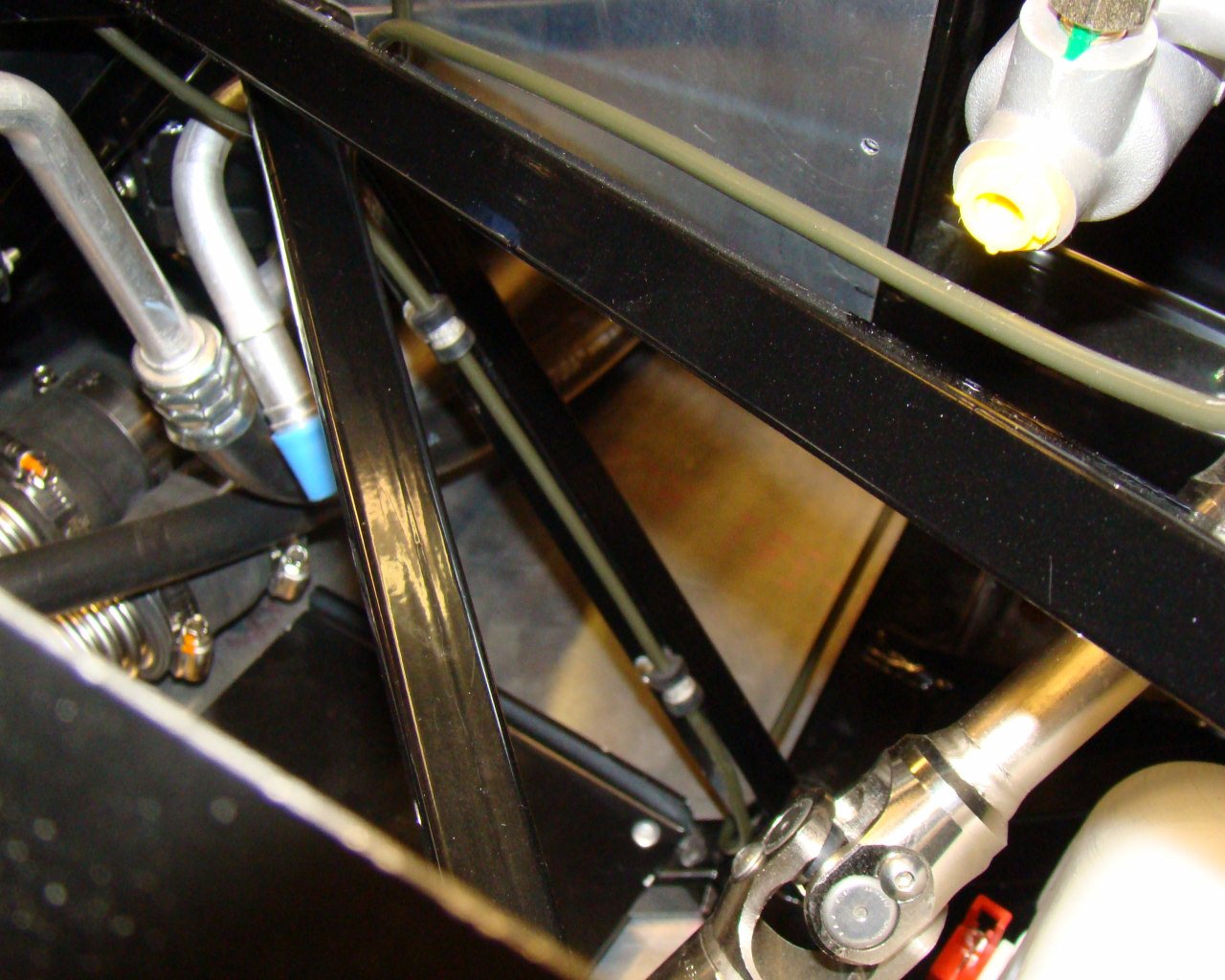

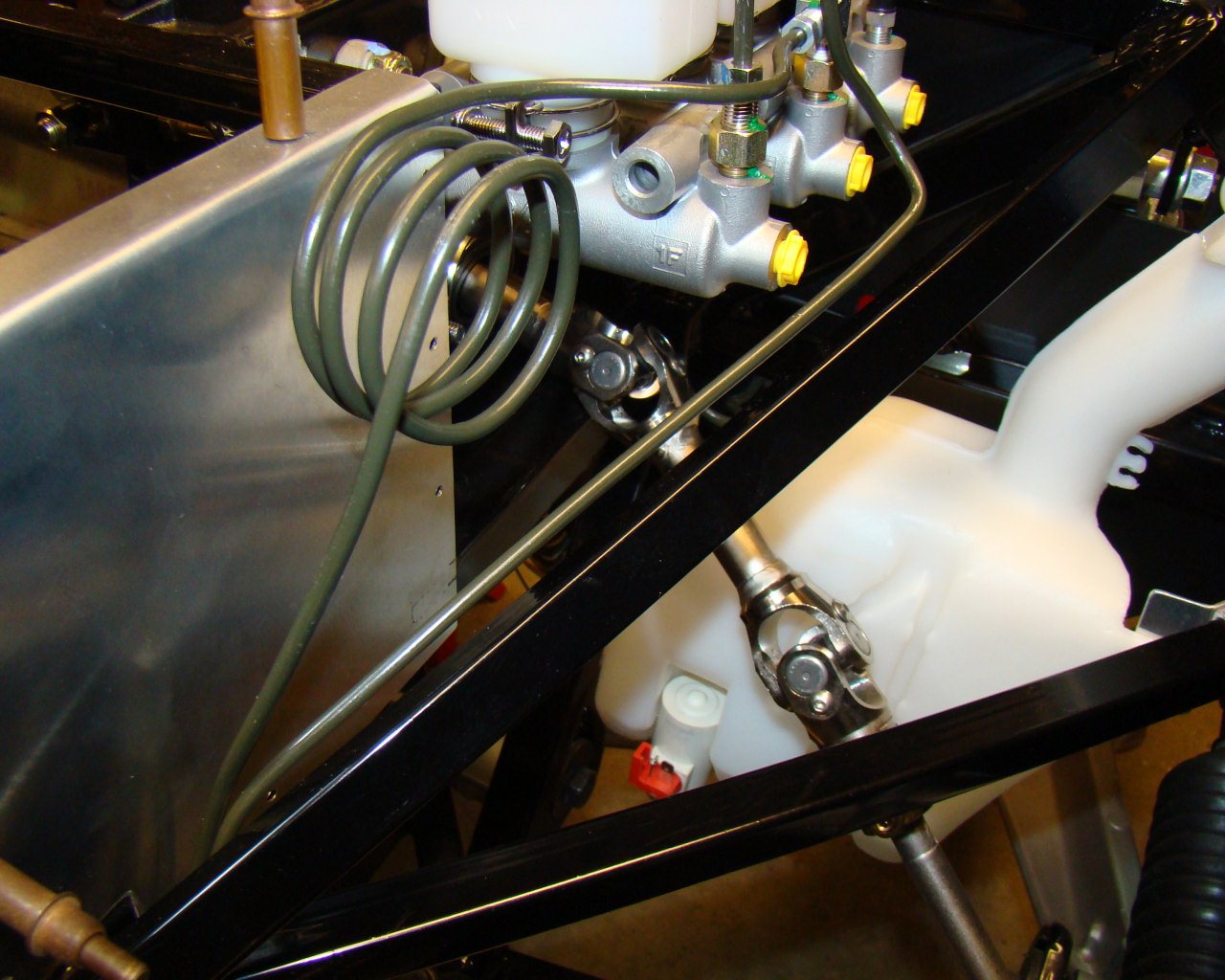

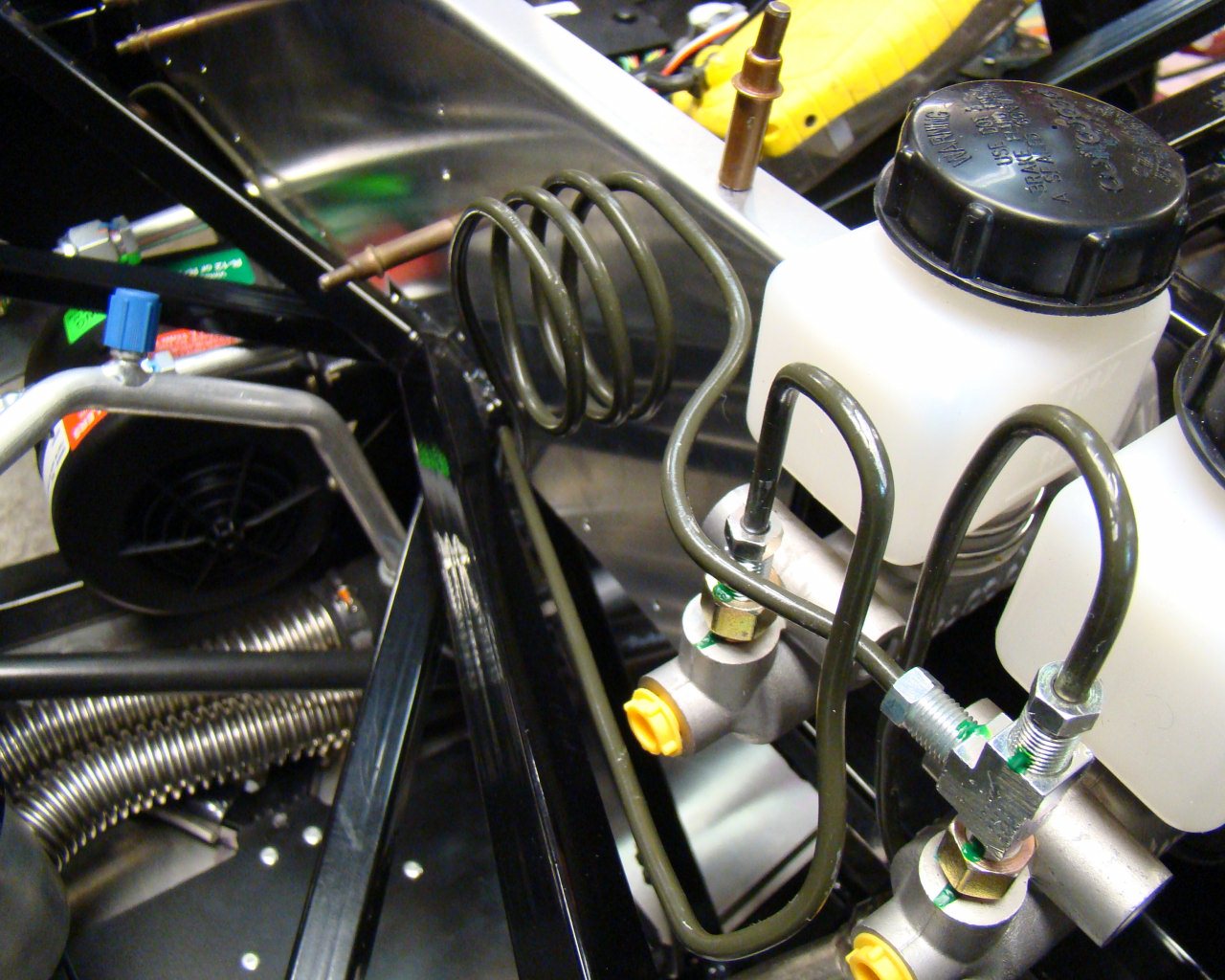

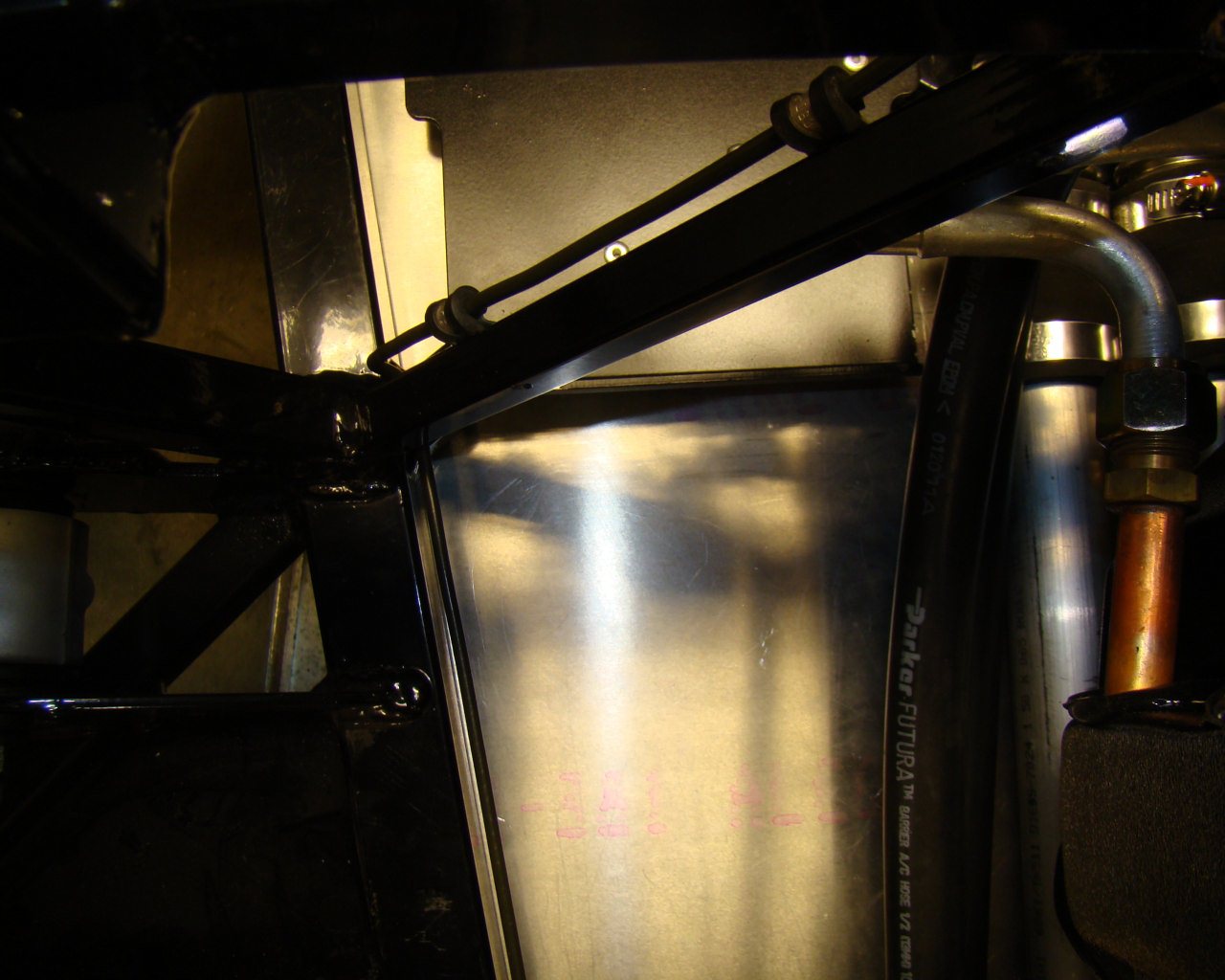

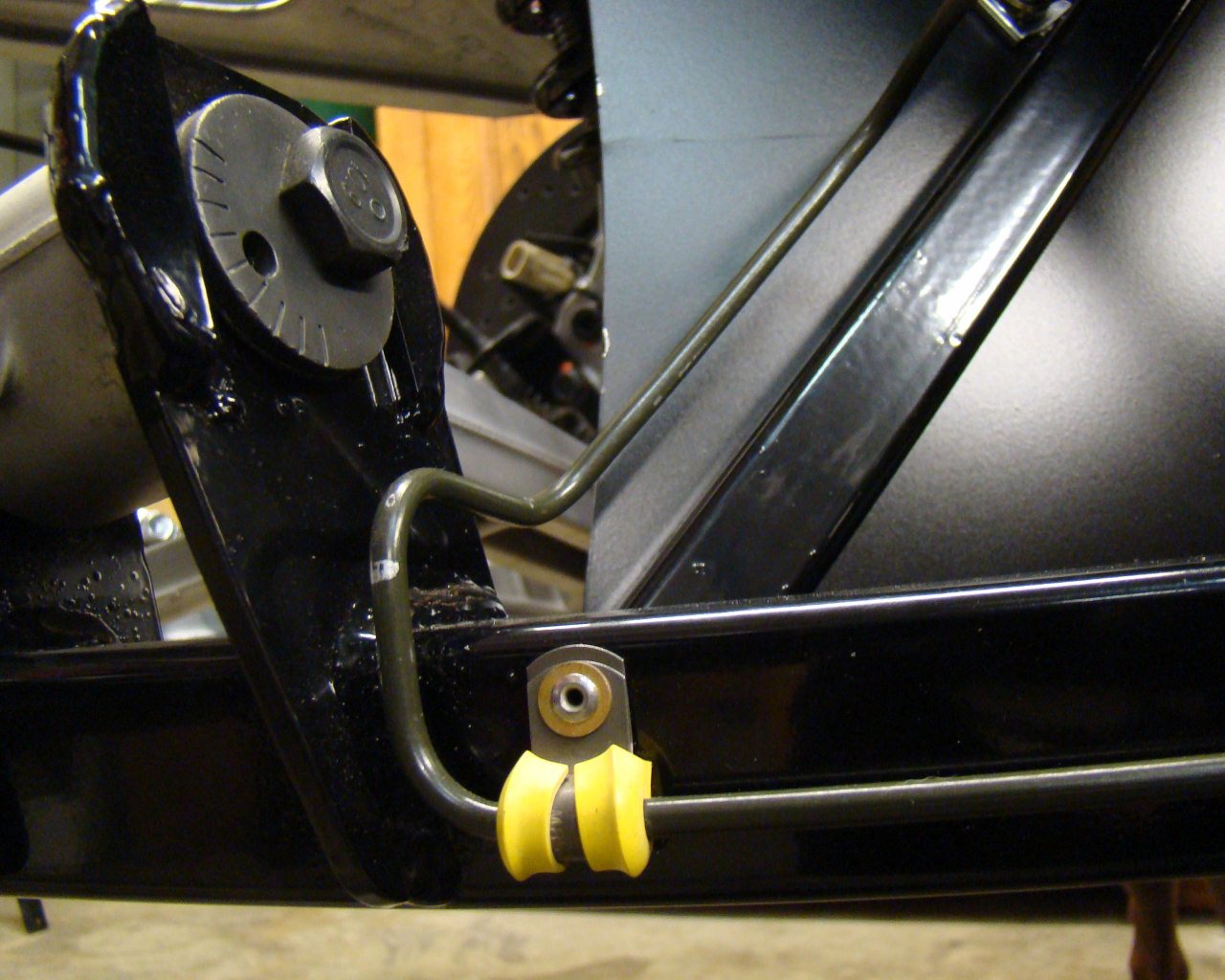

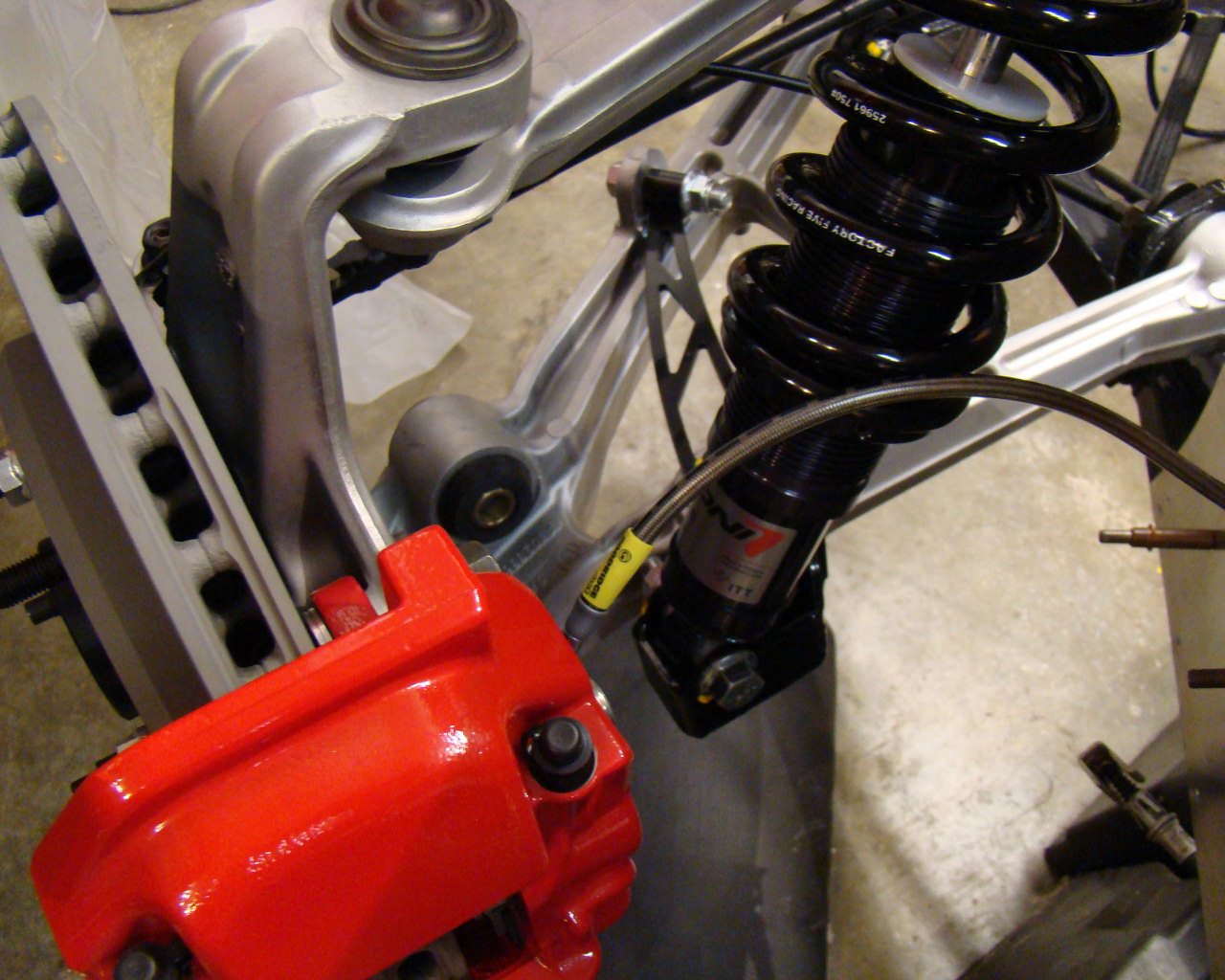

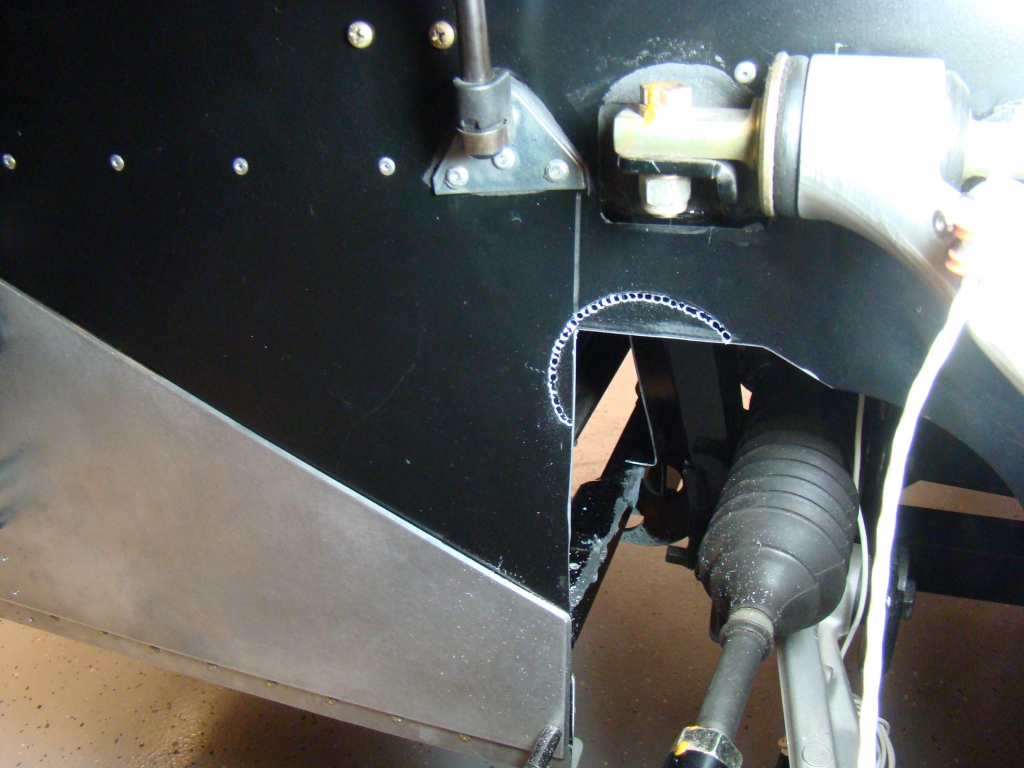

The pictures on the bottom begin with brake line routing.

Bending the lines and achieving the correct path (within clamping

distance of frame members) is not the easiest thing to do.

Starting with a 60 - 80" line makes it very difficult to manipulate

within the working areas. In many cases you will need to

measure and make bends further down the line to complete the bends

around and along frame members long before you actually get to the

ends. Also, the last bends at the front wheels are

challenging but small radii are possible using a tubing

bender. Various tools, pieces of wood, screw drivers and

whatever else you can use to assist will be needed. Your

fingers alone won't hold up and the tubing gets stiff when you have

bends in close proximity to

one-another.

Full

left

Centered

Full

Right

To

neaten things up I used a piece of the door seal (The FFR seals

separate between the bulb and the part that attaches onto the sheet

metal edge pretty easy. All that time I spent cutting the

radiator box upper seals (the ones under the hood) and they end up

falling apart after resting my arm on them for a few hours off and

on. I noticed this while doing the doors but the one on under the

hood separated along a two foot section. So...I used the

donor Corvette door seals instead). The piece you see is what I cut

off the FFR seal.

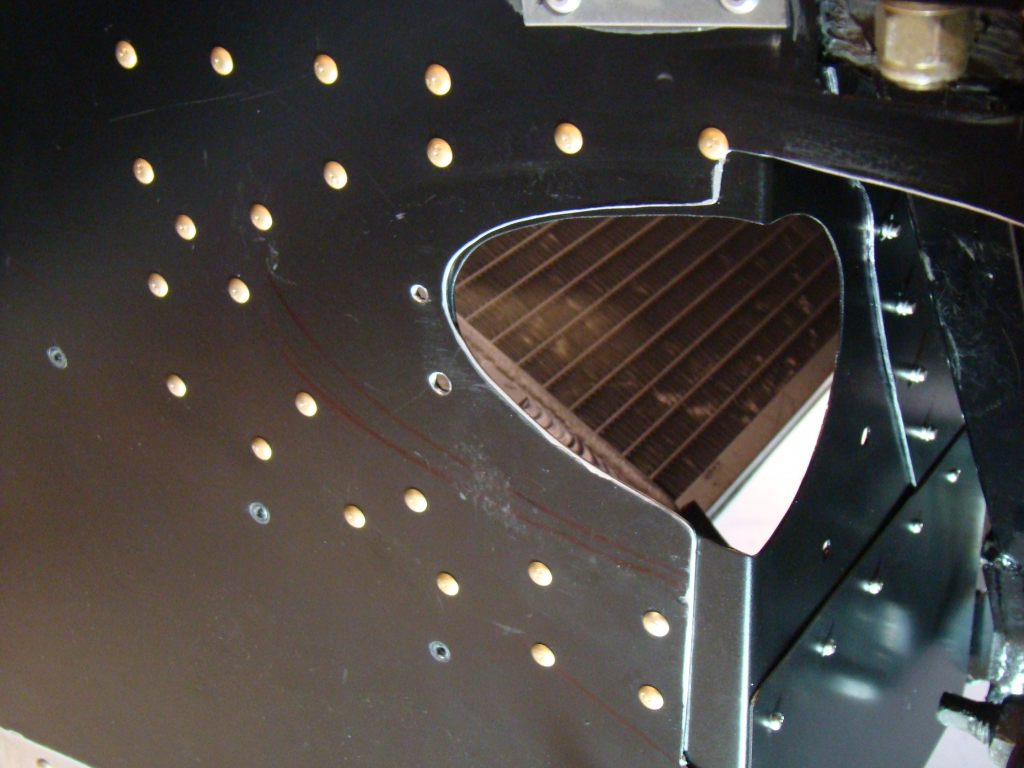

There was easy access to the outside

so I used MS20427 4-2 rivets the old fashioned way. A rivet

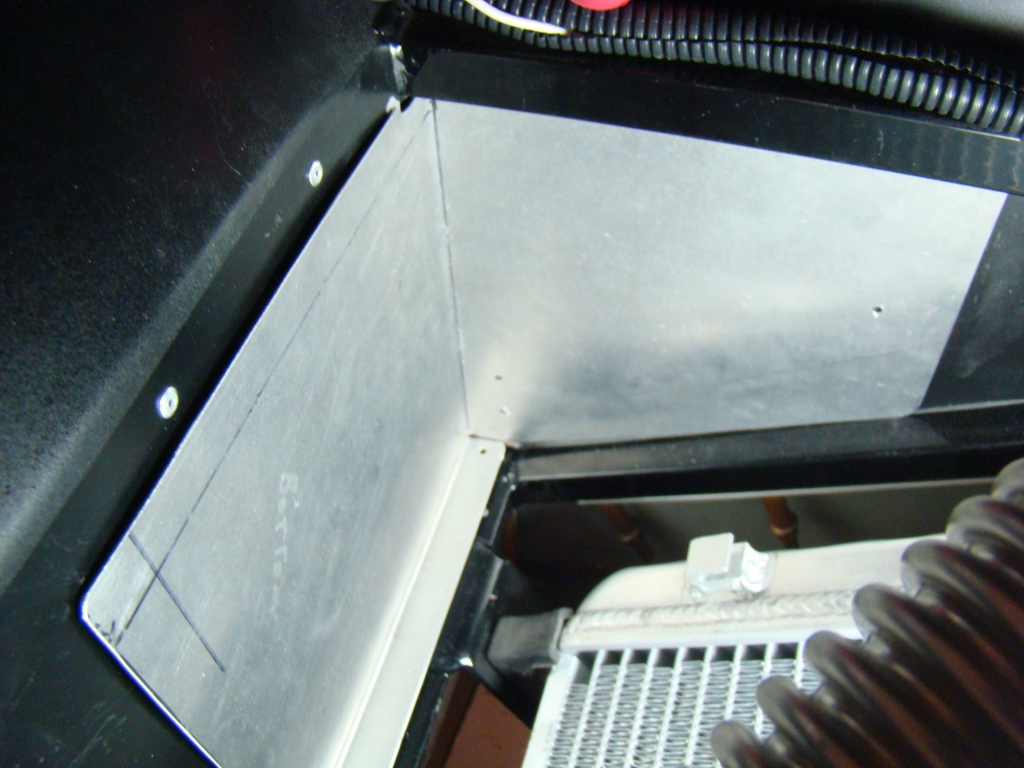

gun and bucking bar. Note the lower radiator box closeout

incorporated into the doubler and aft radiator box sheet metal

wall. I didn't need the entire corner cutout quite as big as

what I covered with the doubler. Only the radiused area is

needed.

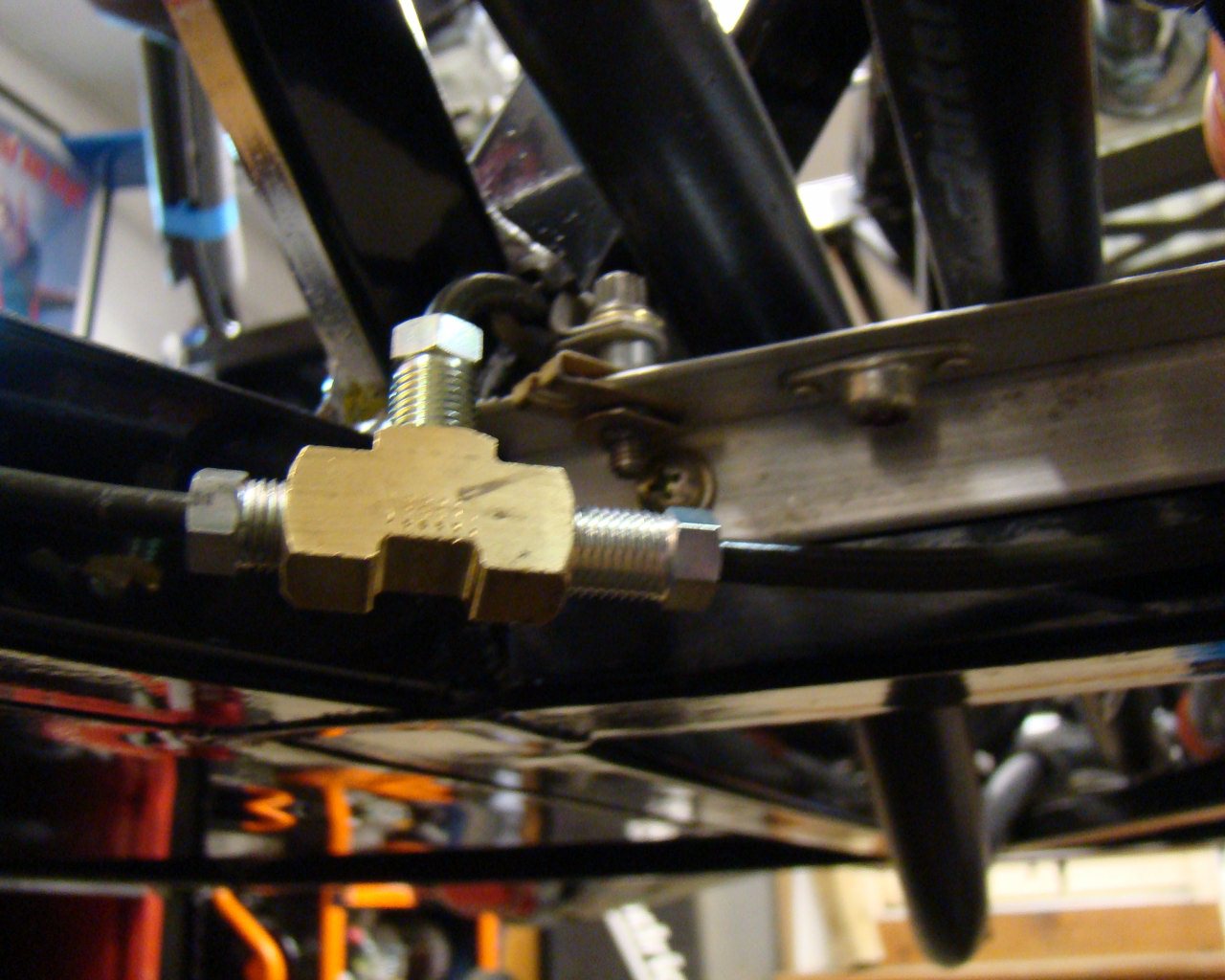

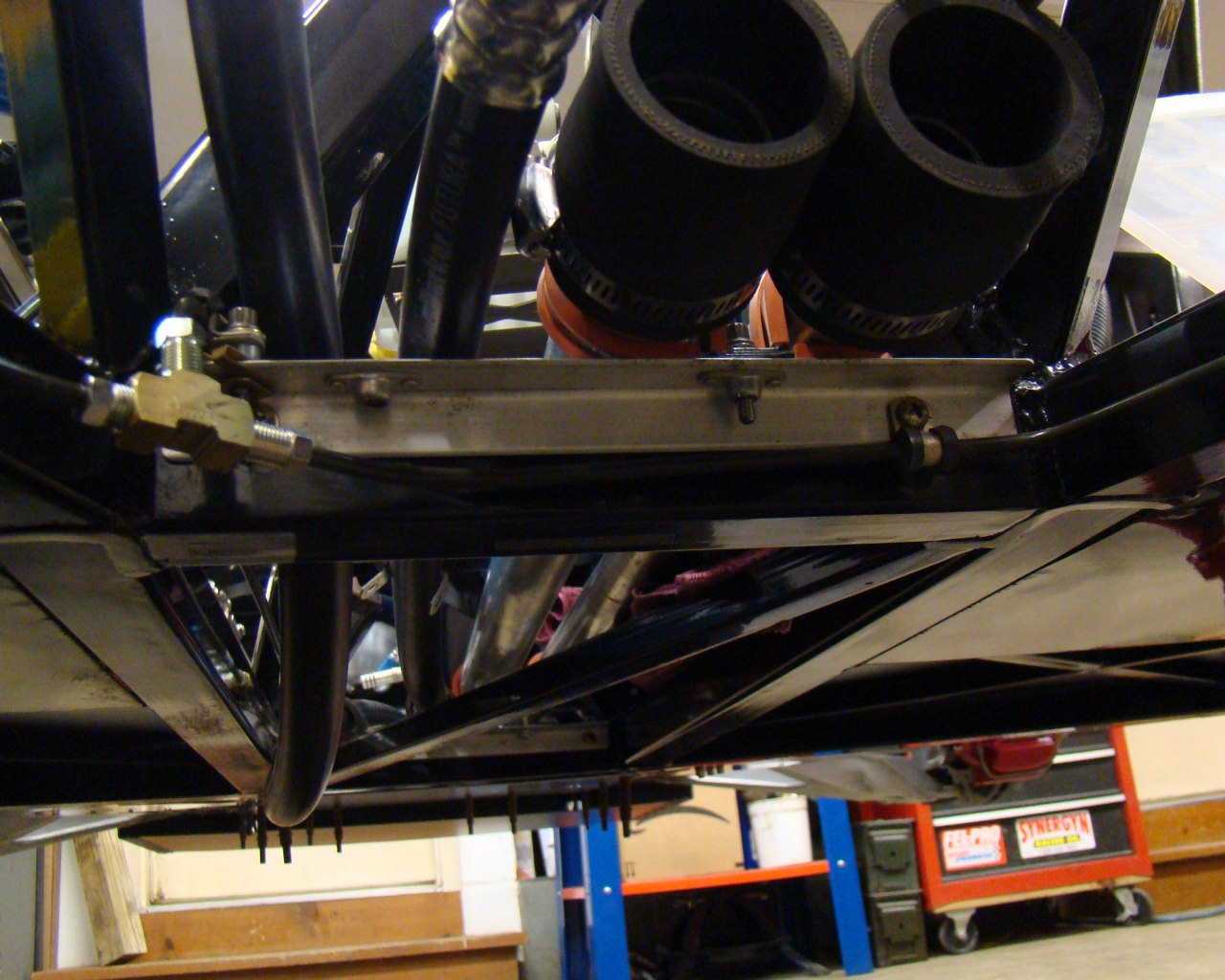

This is the

doubler, L-angle, shims and lower radiator closeout panel riveted

as an assembly. The lower radiator closeout is the primed

area in the middle of the picture just aft of the radiator and

under the frame. The bottom of the panel attaches to the

undercarriage or belly panel which is part of the modified radiator

box. This seals and closes off the left and right corners which are

normally open on a stock GTM. For whatever reason, FFR's

design was a little flimsy and incomplete on the aft radiator box

corners.

Ultra Gray RTV

and self tapping 10-24 screws hold the opposing flange

on.

Note the cutout

to clear the frame member

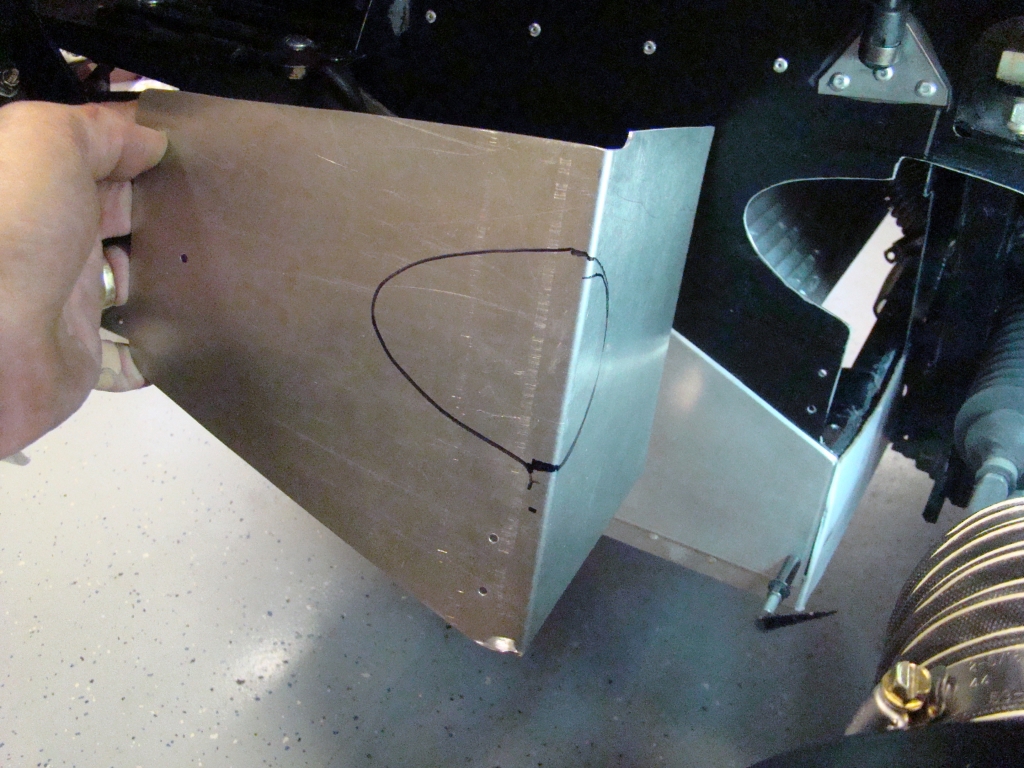

Trial fitting and preparing the

attachment flanges off the car on the

doubler.

This is the inside

doubler that reinforces the corner and provides a little more

bearing surface to run the screws and bolts through for attaching

the duct later. It also ties in the lower closeout panel

which completes the closure of the bottom sheet metal panel under

and behind the radiator box aluminum.

After drilling through the assembly, I

used 3/16ths soft aluminum rivets. I actually bonded all the

pieces together and then did the

riveting.

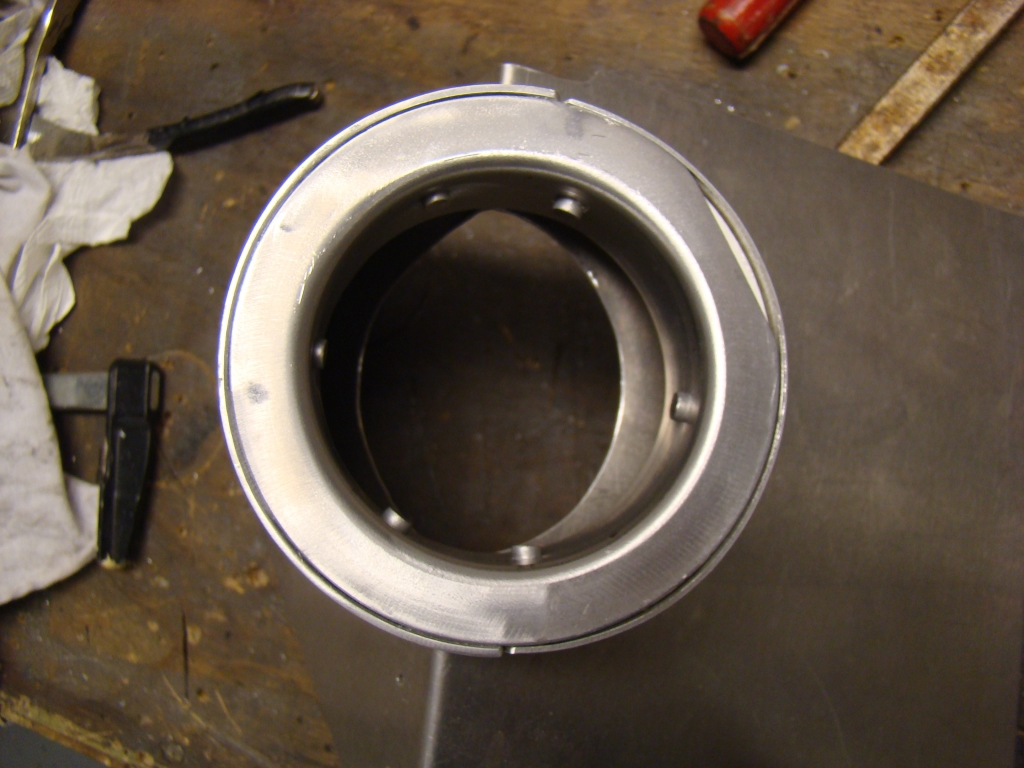

3"

PVC pipe and a coupler ended up making a perfect spacer that took

up the space between the duct diameter and that of the

flange.

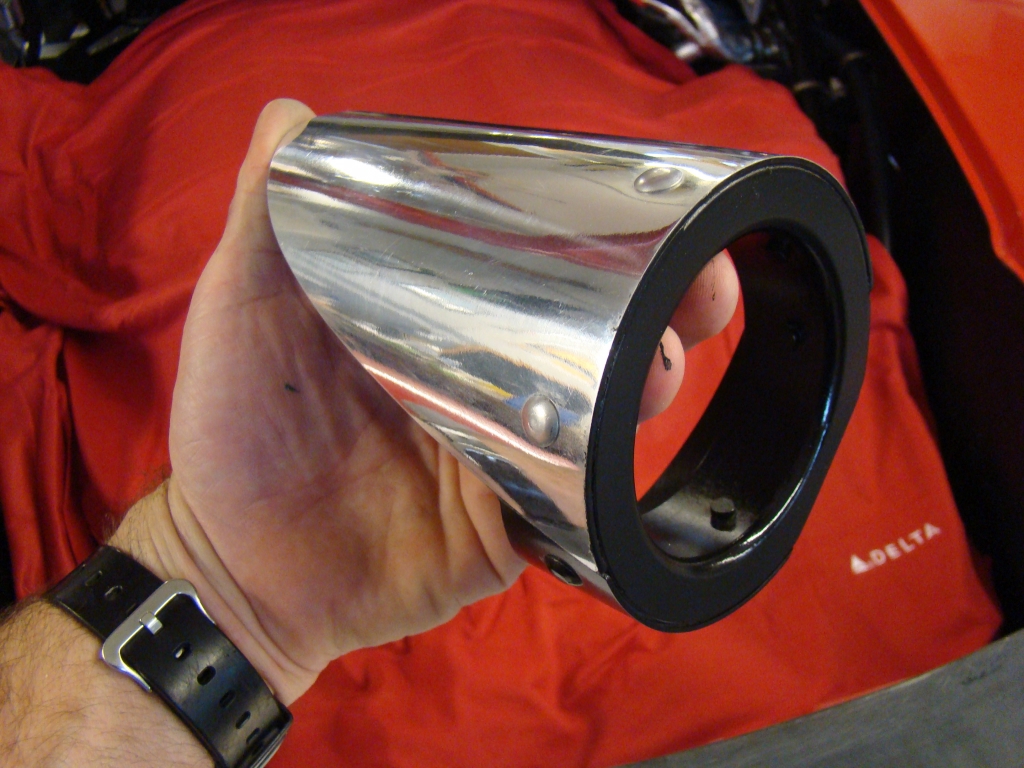

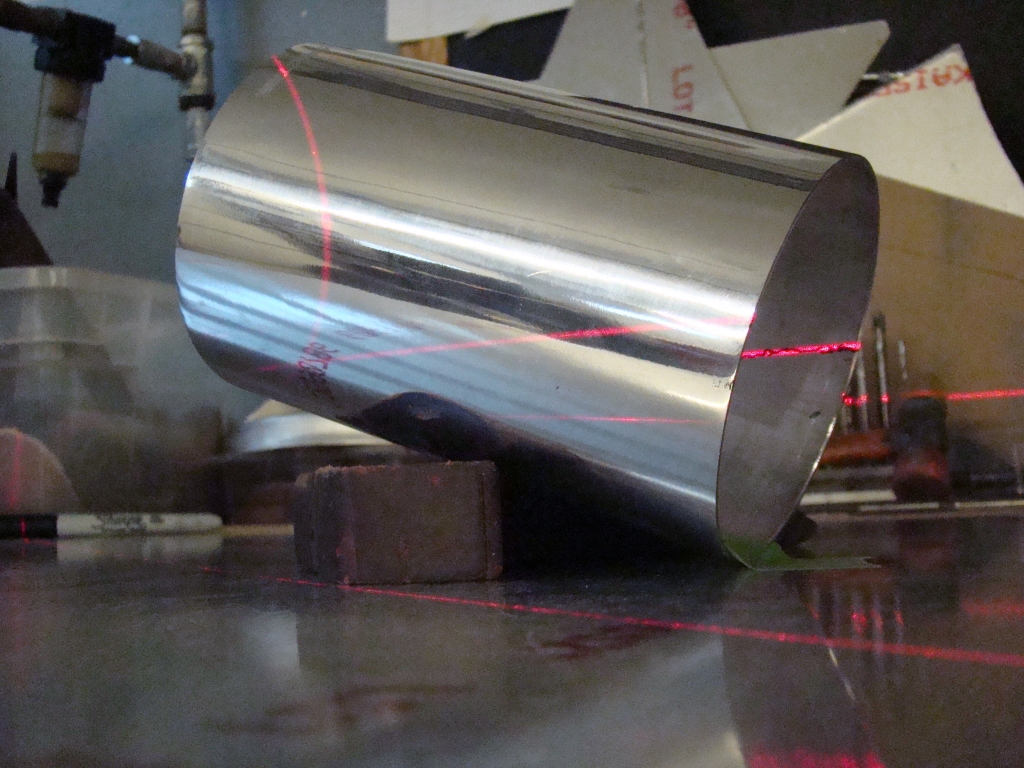

This was an

interesting challenge. I had to cut the duct at the right

point so that when at the correct height at the flange, the

remaining tapered body would lie flat against the side of the wheel

well sheet metal without need for a seal. I wanted a clean

look with all retention done from inside using clip style

nuts. The bandsaw I currently use doesn't accomodate a cut

like this without risk to the piece or the person cutting it.

A good bandsaw would have worked with proper setup but this was

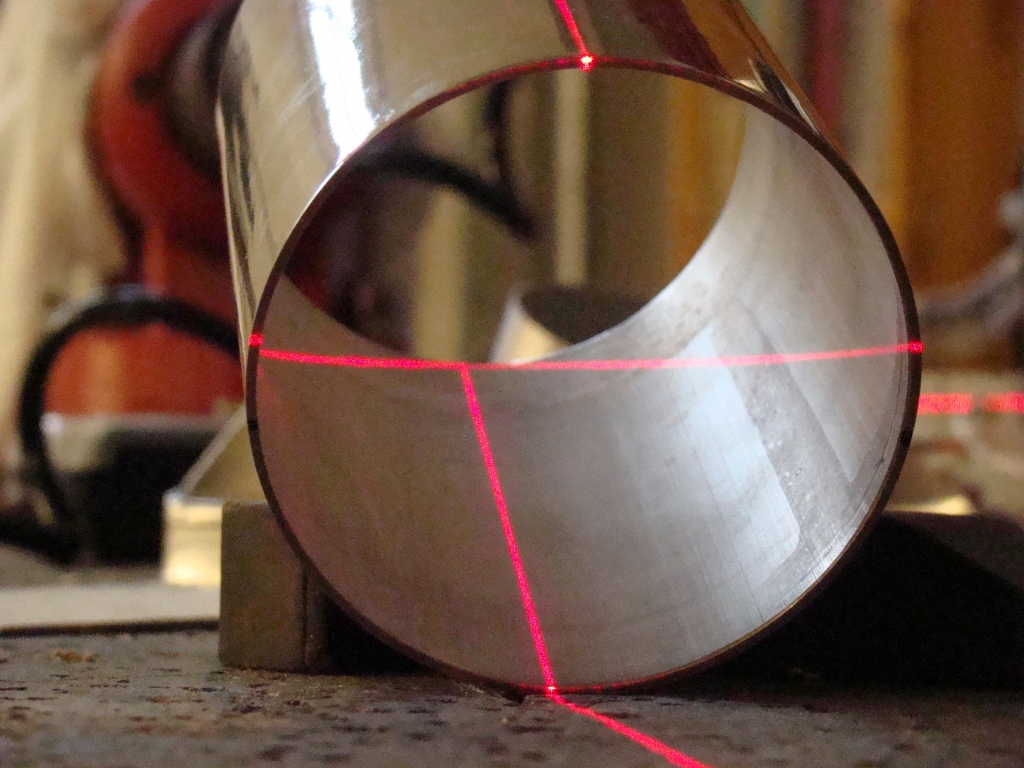

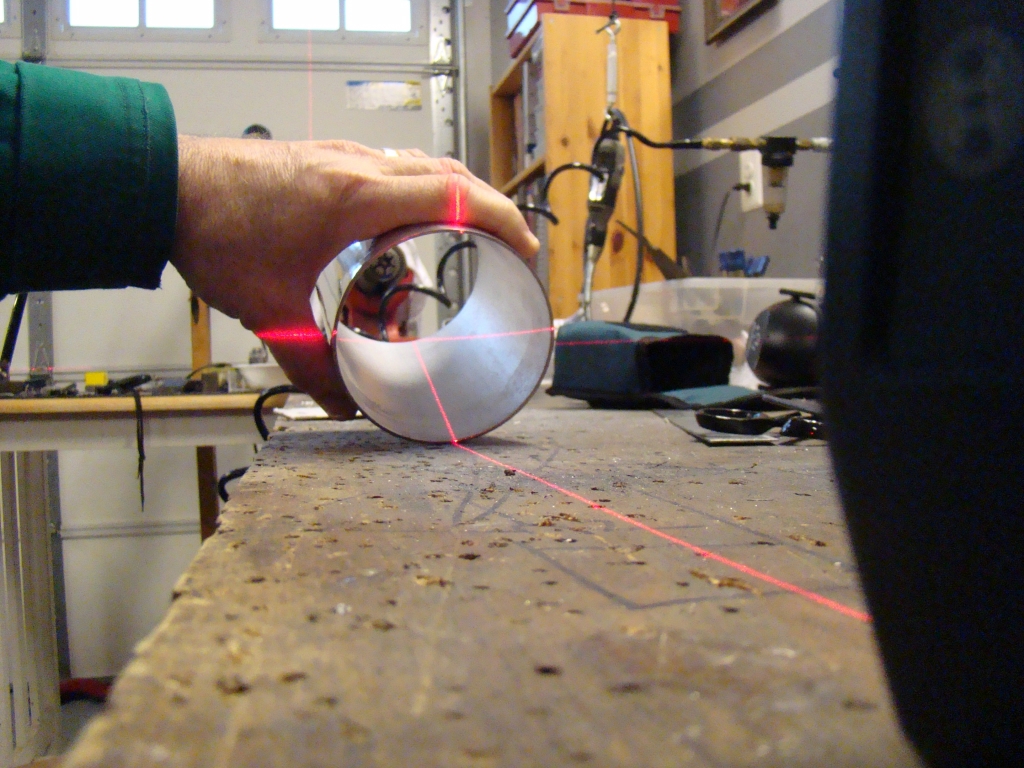

much easier. The two challenges are getting the cut lines correct

and then making the cut without error. I remembered I had a

double line self leveling lazer which worked perfect for projecting

the line for the cut. After I traced the lines, I made the

cut with a 3" cutting wheel.

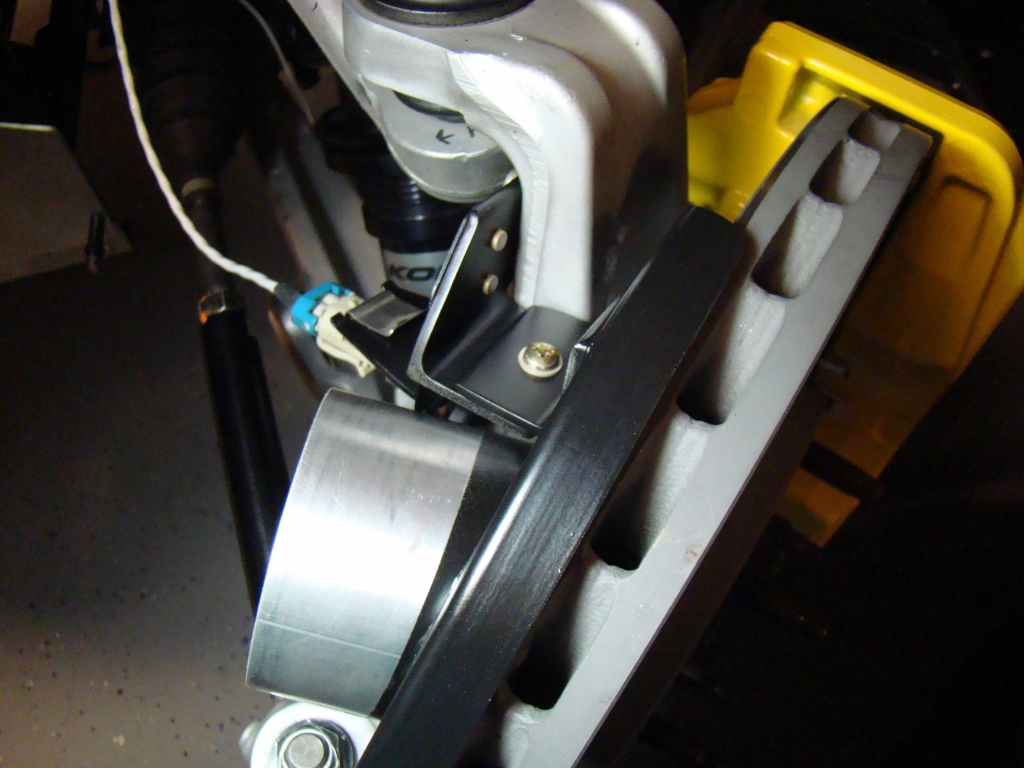

The modified

connector holder riveted to a new bracket.

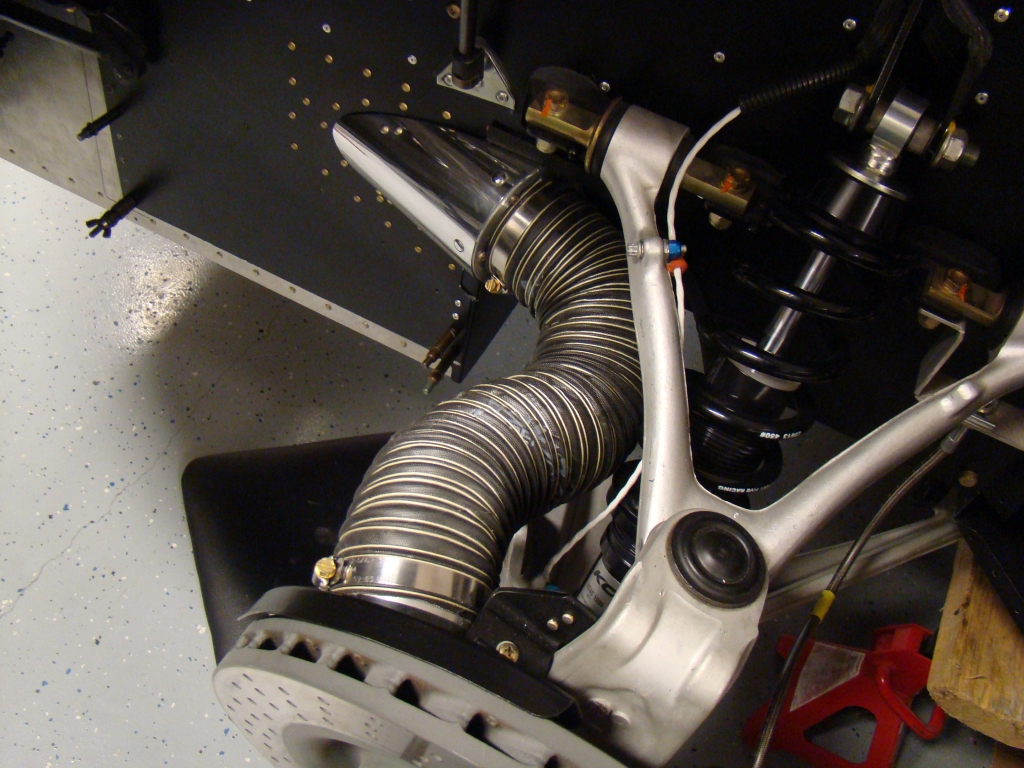

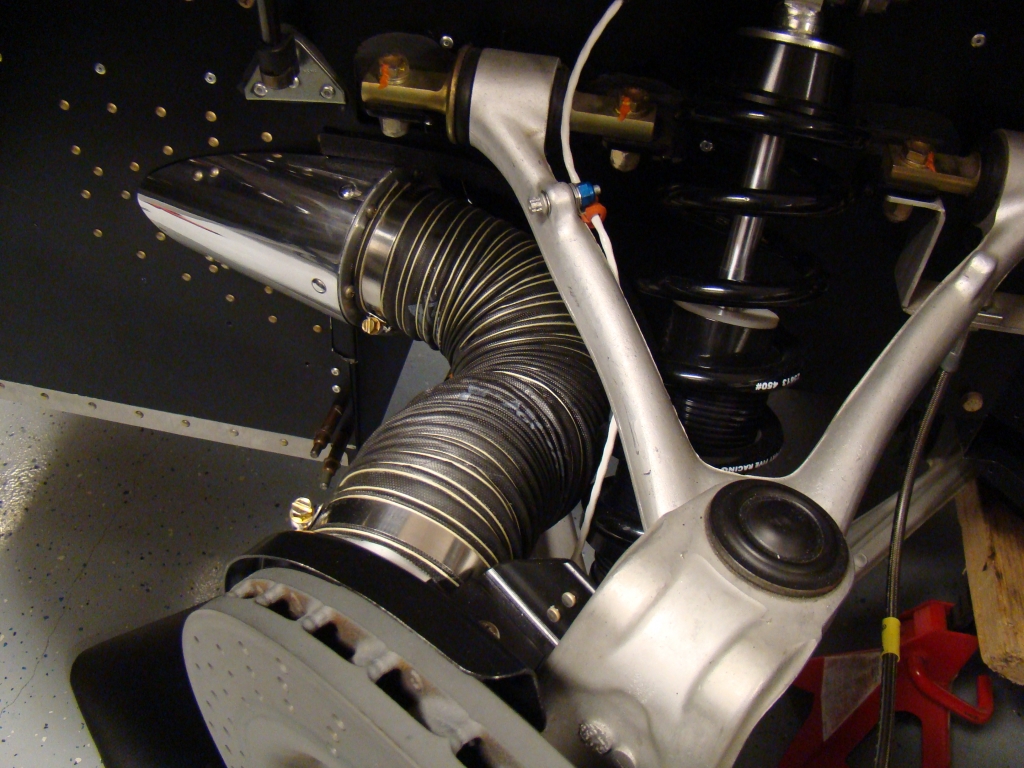

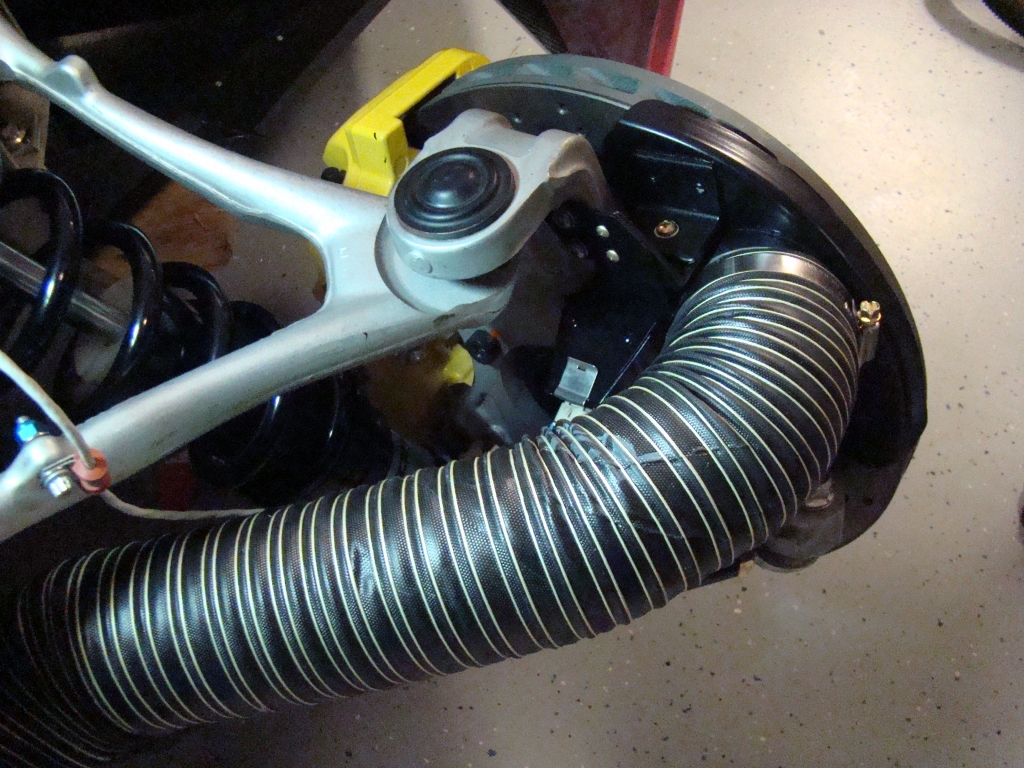

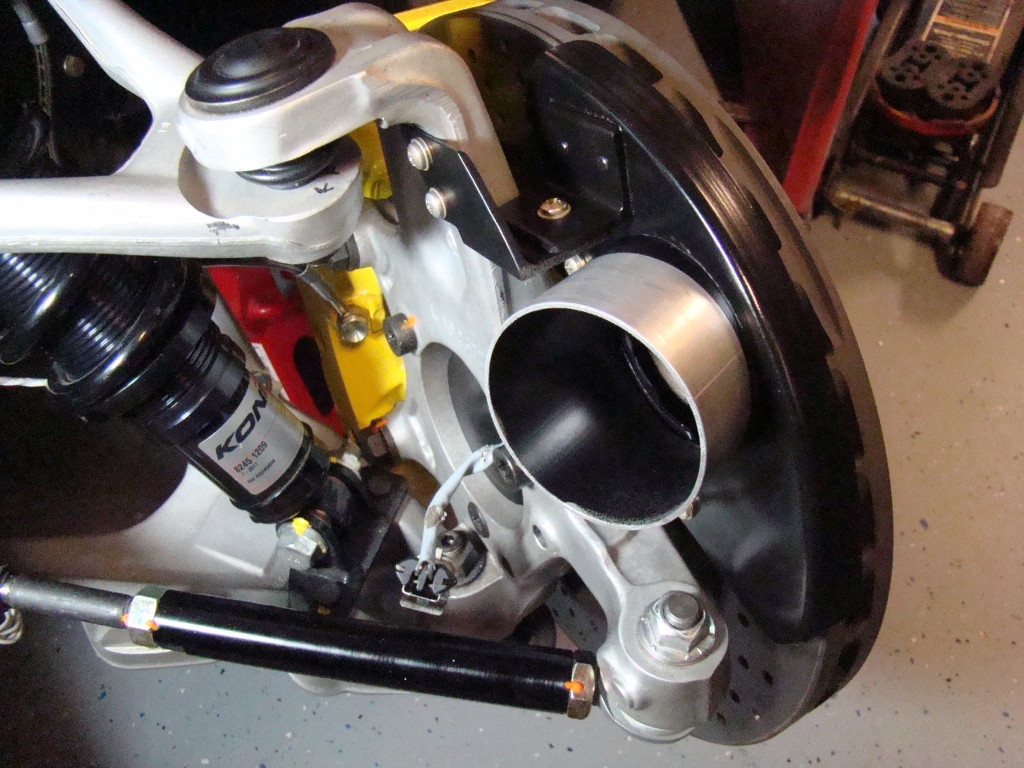

With spindle duct

mounted

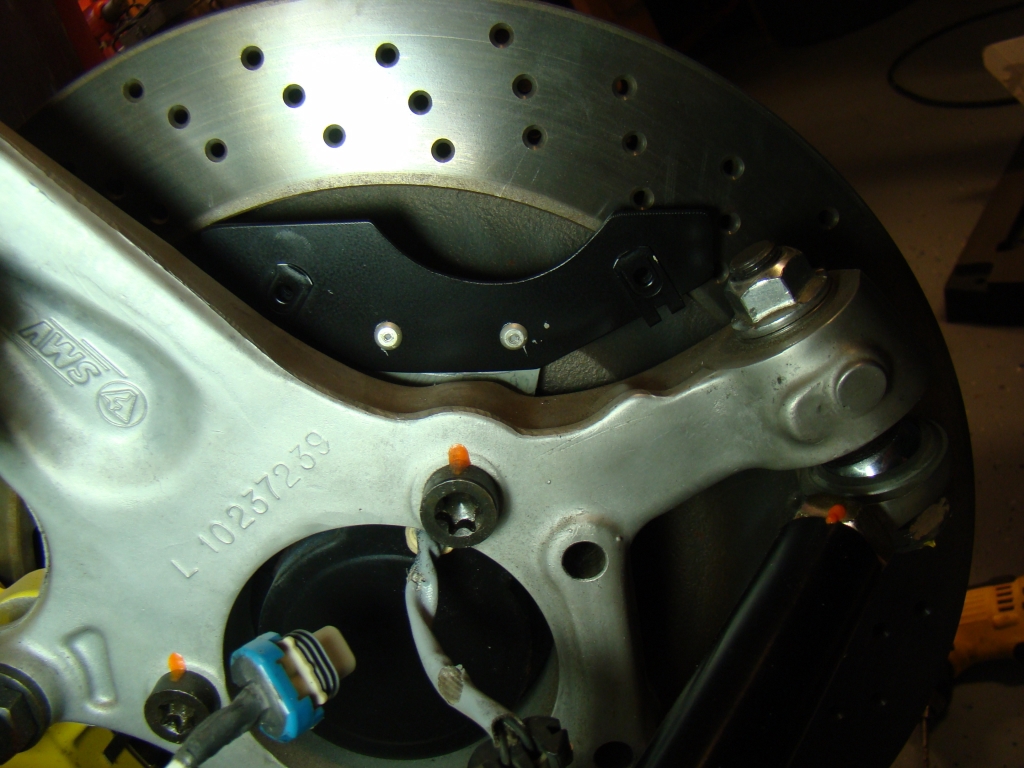

In

addition to the backing plate, I fabricated a .125 angle and tapped

the spindle for 10-24 screws installed with blue

Loctite.

I cut off the wheel speed sensor connector mount

at the bend, leaving enough steel to attach a backing plate for the

spindle duct. I saved the piece I cut off to be riveted to an

aluminum bracket and re-used for the speed sensor connector

later.

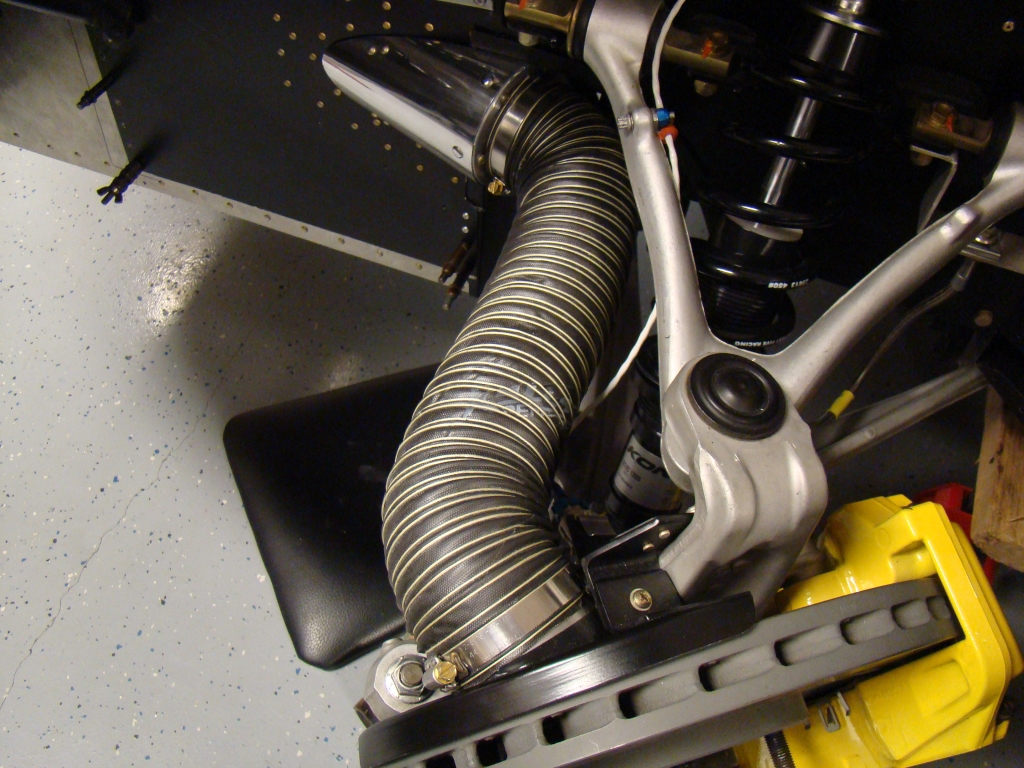

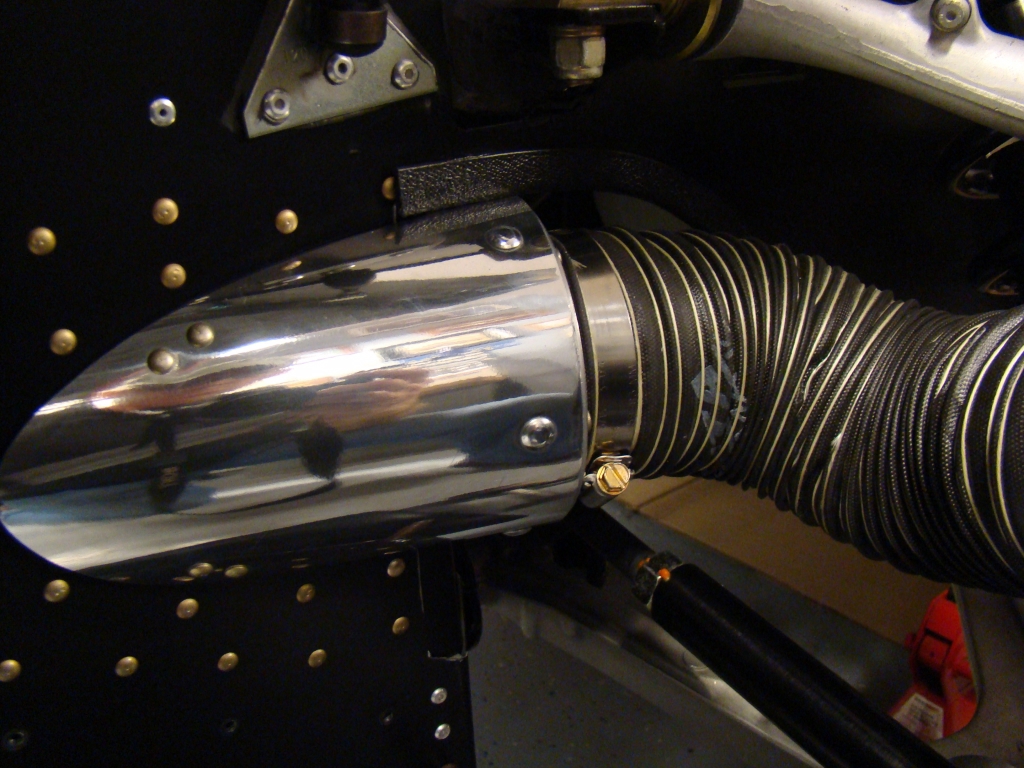

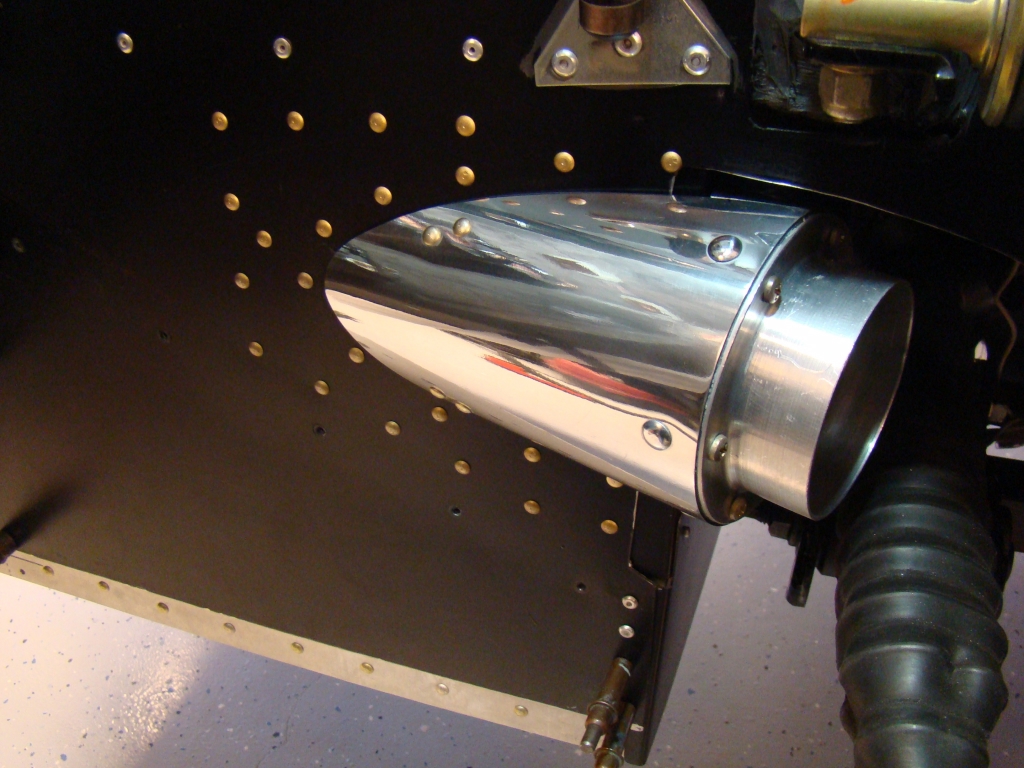

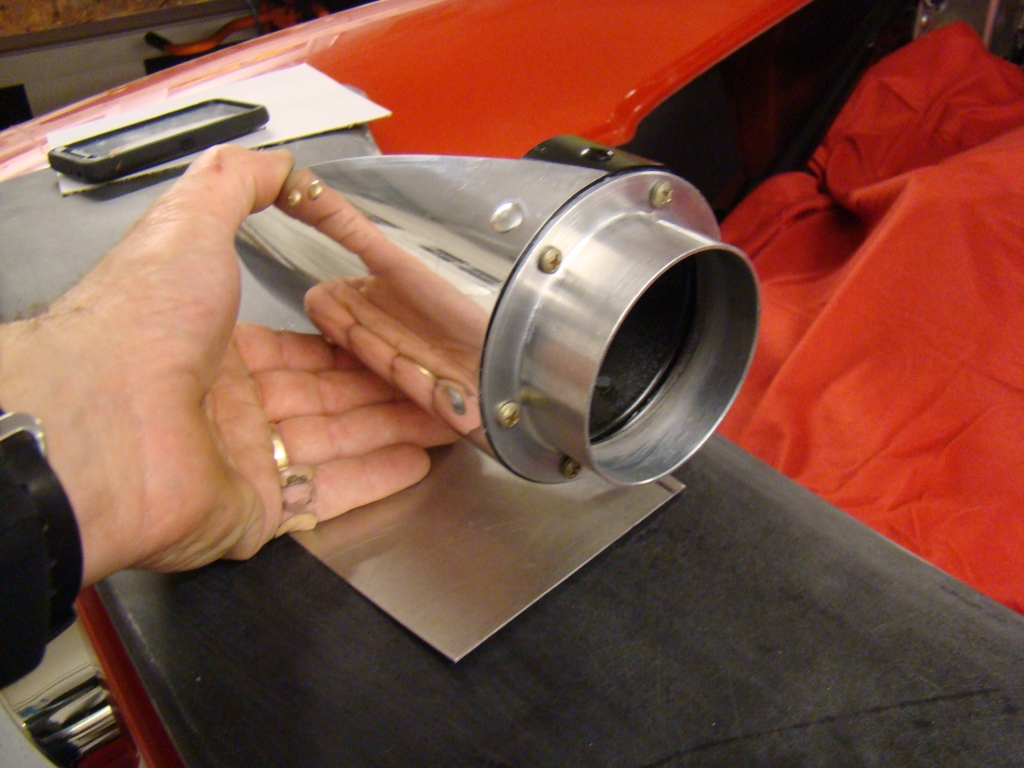

The parts below are AllStar performance spindle

mount ducts. The flanges are 3" flanges from Aircraft

Spruce.

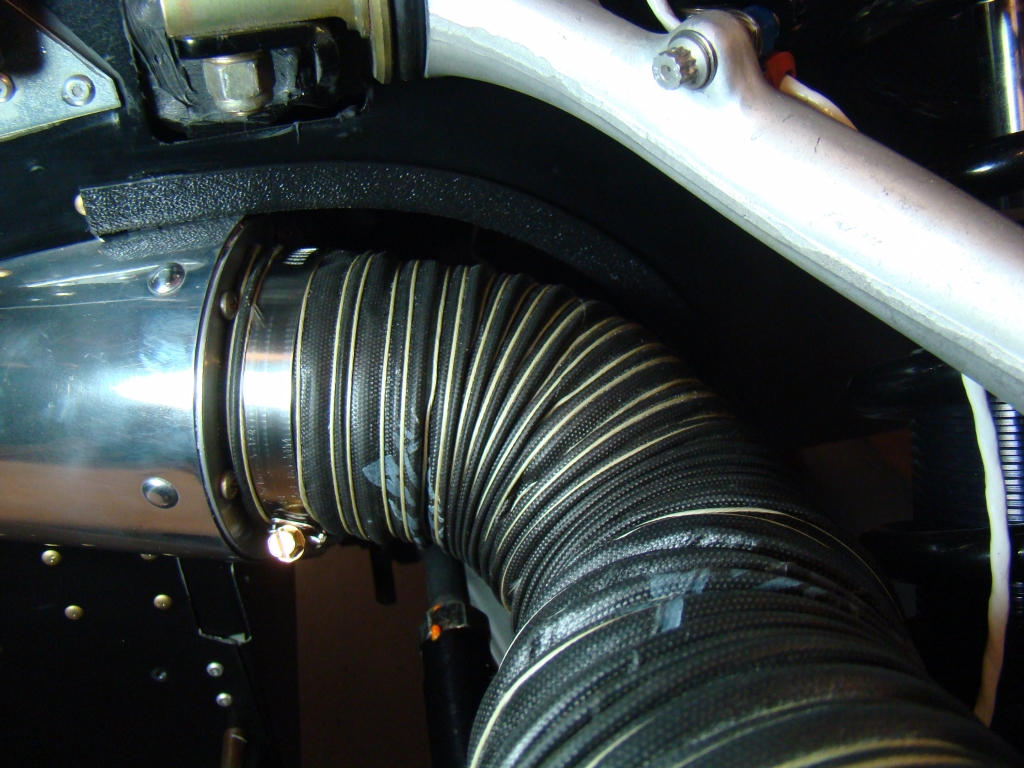

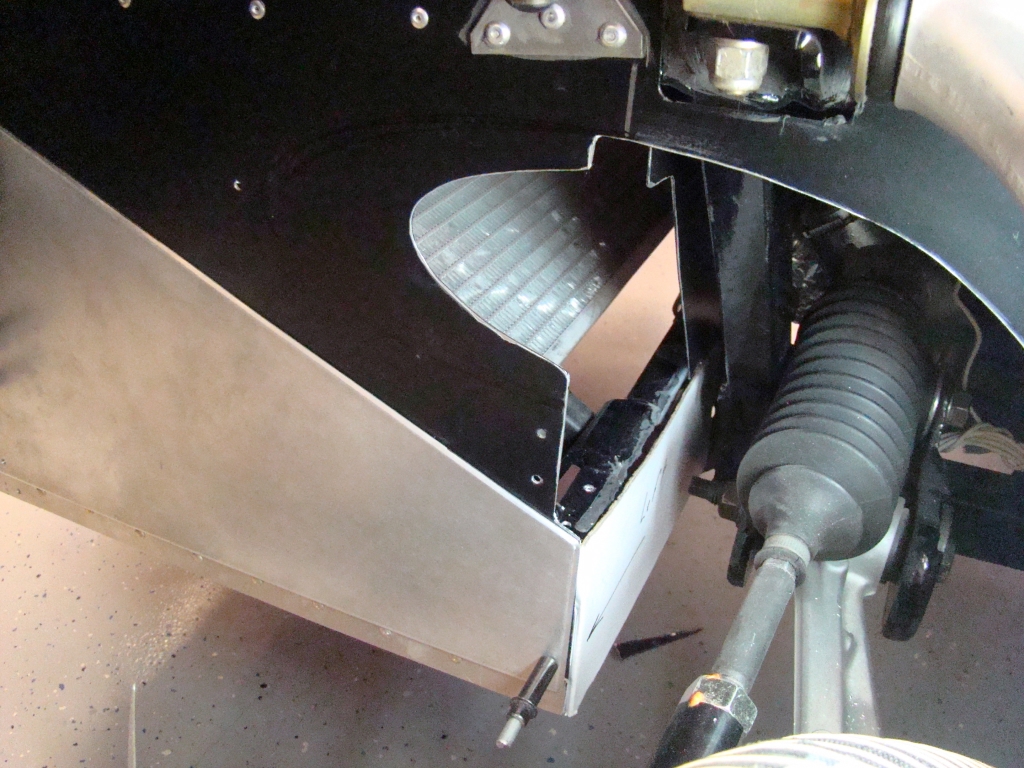

After looking over the radiator box and airflow,

not to mention access and all the other considerations (Angle,

interference, airflow temperature, velocity etc), I had to figure

out the solution and then build to it vs hacking things up.

By the time I made the cut, I already chose a four inch Spetre

polished tube as the best way to get the air flowing at an

angle. I also had to figure out how the flanges and duct

would attach before knowing all of this would fit and not interfere

with the steering at different heighs of the suspension. I

used a jack and moved the steering full left and right while

holding the 3" ducting in the approximate position to understand

how the duct would move and flex. Surprizingly, the duct

flexed like an accordian when angled properly. Anyway, I

began making the cutout a little at a

time.