BODY FITTING AND FIBERGLASS

BODY FITTING AND FIBERGLASS

THE BELOW PHOTOS SHOW MANY PARTS OF THE BODY ALIGNMENT AND FITTING. THIS INCLUDES THE NOSE, HATCH AND MANY OTHER AREAS.

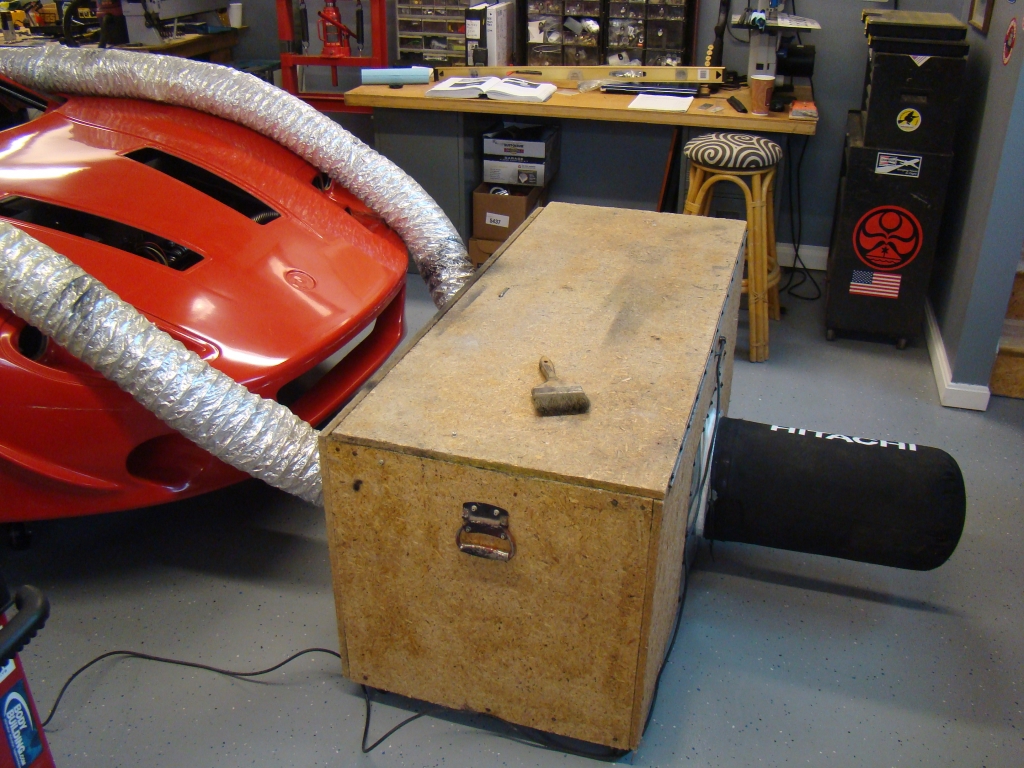

THIS SHOWS A VENTILATION BOX USED TO PULL SANDING DUST AND FUMES FROM WORKING AREAS. THE AIR FLOW IS PRODUCED FROM A HOUSEHOLD 'SQUIRREL CAGE' A/C UNIT BLOWER. THE AIR FLOWS THROUGH THE 6 INCH HOSES, AND INTO DOUBLE SETS OF 20X25 HOUSEHOLD A/C UNIT FILTERS HOUSED WITHIN THE BOX. THE BLACK BAG IS A FINAL FILTER THAT CATCHES PARTICLES THAT COLLECT ON THE FAN HOUSING AND BLADES. THE UNIT PRODUCES ENOUGH FLOW TO NEARLY ELIMINATE ALL DUST WHEN HEAVY SANDING AND TRIMMING IS DONE WITH PNEUMATIC SANDERS AND GRINDERS. THE HOSES ARE MOVED ADJACENT TO THE WORK AREAS

BASIC HATCH FITTING VIDEO

FITTING OF THE HATCH AND GLASS

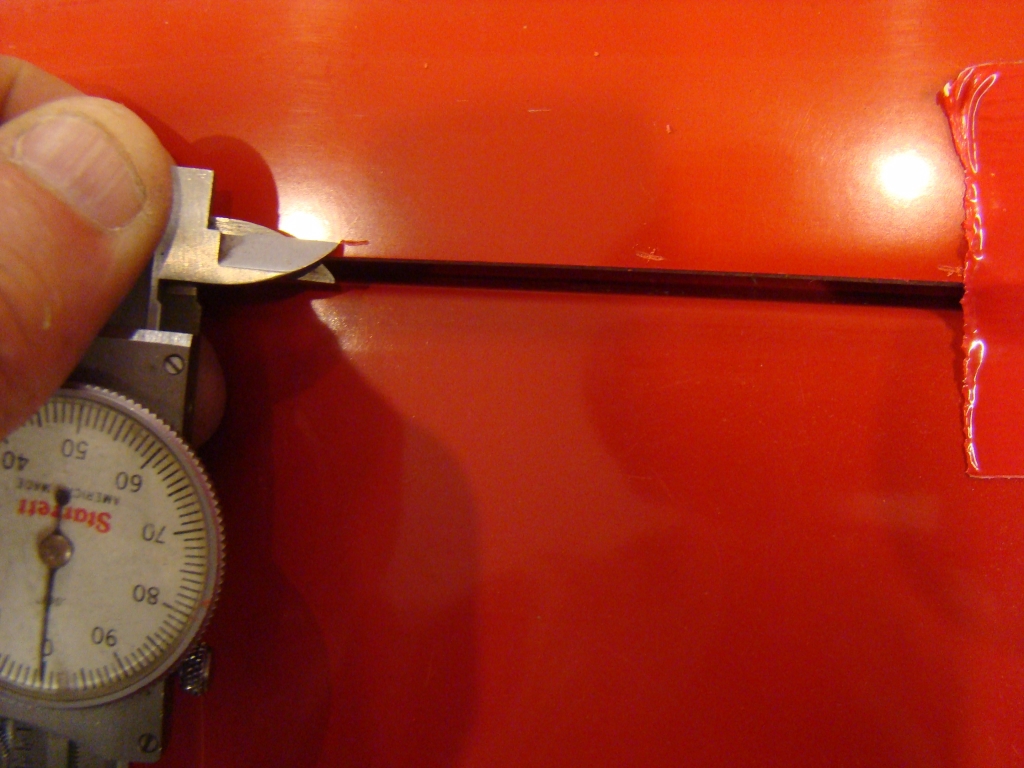

FITTING THE GLASS - USING A CARDBOARD TEMPLATE OF THE GLASS IS MUCH EASIER THAN TRIAL FITTING THE ACTUAL GLASS. IT PREVENTS DAMAGE TO THE HATCH GLASS AND GIVES YOU A GOOD IDEA OF HOW THE GLASS WILL FIT. CUT THE TEMPLATE TO THE EXACT SIZE OF THE GLASS AND MASSAGE THE CARBOARD UNTIL IT FLEXES ENOUGH TO FORM THE SHAPE OF THE ACTUAL GLASS. THIS IS DONE BY HAND. THE EDGES OF THE CARDBOARD ARE ACTUALLY COMPRESSED SLIGHTLY GIVING IT A THICKNESS SIMILAR TO THE GLASS. TAPE THE TEMPLATE IN PLACE OVER THE HATCH WHERE THE GLASS WOULD GO. DO YOUR TRIMMING AND HINGE ADJUATMENTS WITH THE TEMPLATE IN PLACE. THE GLASS IS ACTUALLY SLIGHTLY LARGER THEAN THE FIBERGLASS AND MUST BE CENTERED IN THE BODY OPENING. CHECK ALL SIDES AND ADJUST THE HATCH SO THE GLASS IS SPACED AWAY FROM THE BODY EDGES EVENLY ON ALL SIDES. (SOME WON'T BE PERFECT BUT THE GLASS CANNOT BE TRIMMED. FOR UNACCEPTABLE GAPS, FILL AND SHAPE WITH FIBERGLASS.

IFITTING THE NOSE

EXTRA LARGE WASHERS TO DISTRIBUTE THE LOAD ON THE FIBERGLASS FOR THE FORWARD HINGE POINT.

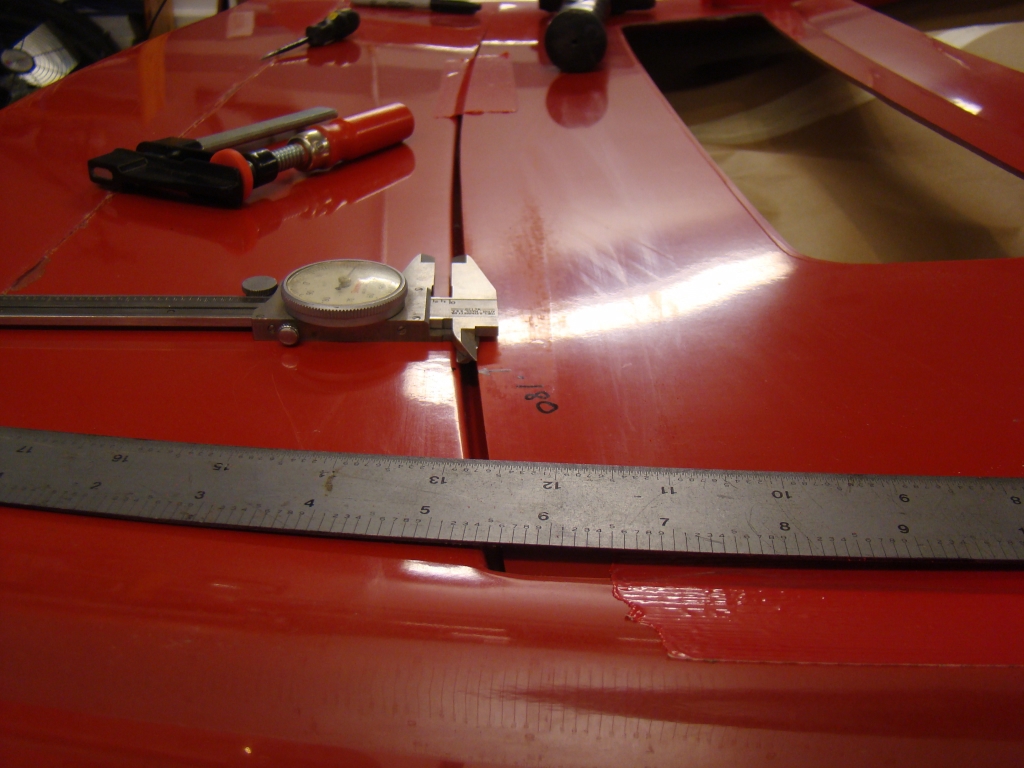

NOTE THE DIFFERENT ANGLE FOR THE DIRECTION OF THE FRONT BODY TRANSITION THAT THE NOSE RESTS AGAINST. ONE AIMS SLIGHTLY INWARD (LEFT) WHILE THE OTHER POINTS OUTWARD. ADDITIONALLY, THE BODY SIDE JUST AFT OF THE FRONT WHEEL WELL IS SLIGHTLY CURVED (LEFT SIDE) WHILE THE RIGHT IS STRAIGHT. THIS IS DISCOVERED BY HOLDING A STRAIGHT EDGE AGAINST THE SIDE WITH JUST AFT AND CENTERED ON THE FORWARD WHEEL. (FRONT TO BACK FROM THE AREA AFT OF THE WHEEL - BACK TO THE FRONT OF THE DOOR.

GETTING THE REAR OF THE BODY CENTERED AND MOUNTED

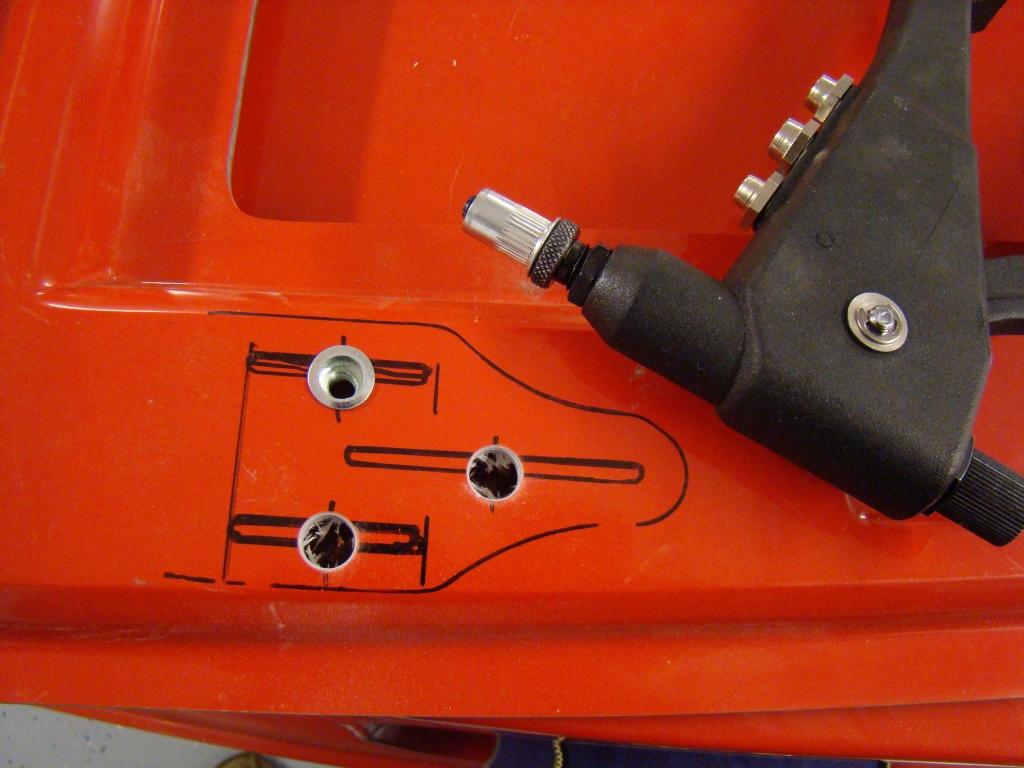

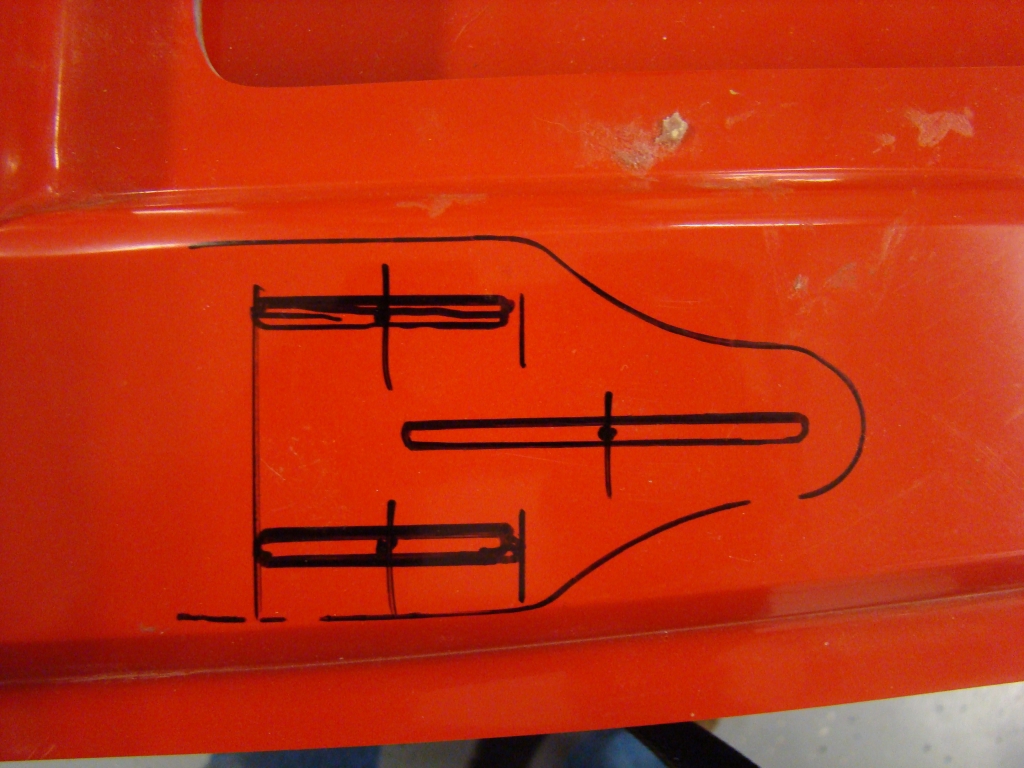

ONCE POSITIONED i DRILLED HOLES THROUGH THE BODY IN THE LOCATION THAT WILL BE BEHIND THE LICENSE PLATE

CLAMPS ARE USED HERE TO ADJUST AND THEN CLAMP THE REAR LICENSE PLATE AREA AGAINST THE L-ANGLE BOLTED TO THE AFT FRAME

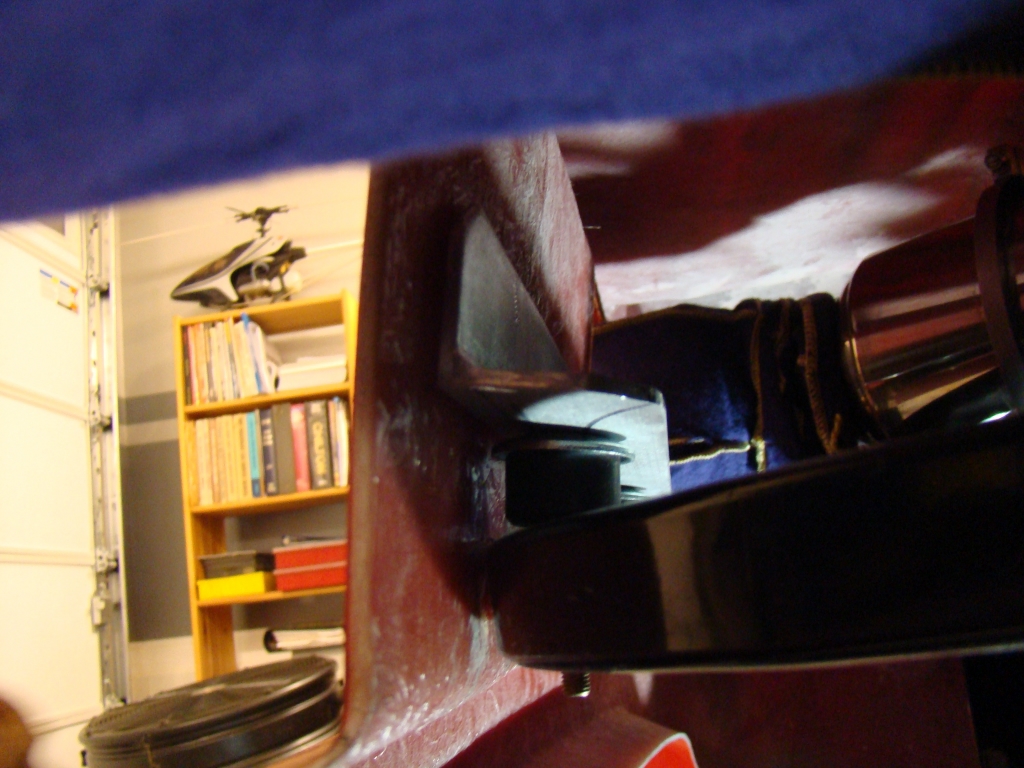

BELOW PHOTOS SHOW THE RELATION OF THE TIRE SIDEWALL AND THE BODY SIDE. A 36' LEVEL IS HELD AGAINST THE SIDEWALL OF THE TIRE. A SMALL GAP CAN BE SEEN. THESE WHEELS HAVE A BACKSPACING THAT WAS CUSTOMIZED AND DOES NOT REQUIRE SPACERS. THIS WAS CHOSEN USING THE BACKSPACING CALCULATOR AND CONSIDERATION/LOOKS OF OTHER GTM'S. THE RESULT WAS A NEAR PERFECT TRANSITION. I COULD BUILD THE FENDER LIP SLIGHTLY, PROVIDING A SLIGHT FLARE AT THE FENDERS IF NEEDED

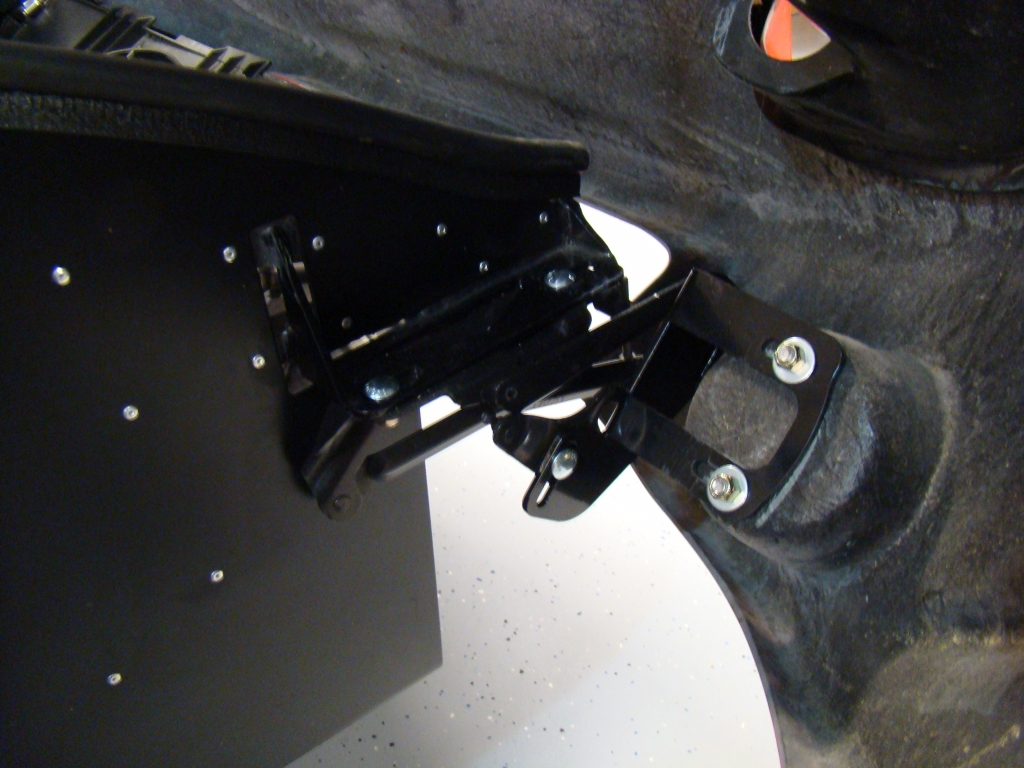

THE BELOW PHOTOS SHOW A SHOCK MOUNTED REAR BODY MOUNT POINT. THIS UTILIZES THE TOP BUSHINGS FROM SHOCK ABSORBERS AND A 1-1/2" .100 ALUMINUM ANGLE 10' LONG. BECAUSE THE REAR FACE OF THE LICENSE MOUNT IS NOT PERPENDICULAR, AN L-ANGLE BOLTED TO THE FRAME WOULD NOT MOUNT FLAT AGAINST THE FIBERGLASS VERTICAL FACE. THE RUBBER ABSORBS VIBRATION, PROVIDES FOR LEFT AND RIGHT HEIGHT ADJUSTMENTS AND ALLOWS THE ANGLE TO FLATTEN AGAINST THE FIBERGLASS ONCE EVERYTHING IS CONNECTED AND TIGHTENED.

NOTE THE SLIGHT ANGLE OF THE REAR LICENSE PLATE MOUNT POINT. THE SHOCK MOUNTED REAR ALLOWS FLEX IN THE L-ANGLE AND REDUCES VIBRATION. iT ALSO PROVIDES FOR ADJUSTMENT TO RAISE OR LOWER THE GAP BETWEEN THE TOP OF THE TIRE AND FENDER ARCH ABOVE IT. TO ADJUST, WASHERS ARE USED WITH BOLTS IN VARIOUS STACKUPS. MINOR ADJUSTMENTS CAN BE DONE SIMPLY BY TIGHTENING.