A/C AND ENVIRONMENTAL

VINTAGE AIR SYSTEM

A/C AND ENVIRONMENTAL

VINTAGE AIR SYSTEM

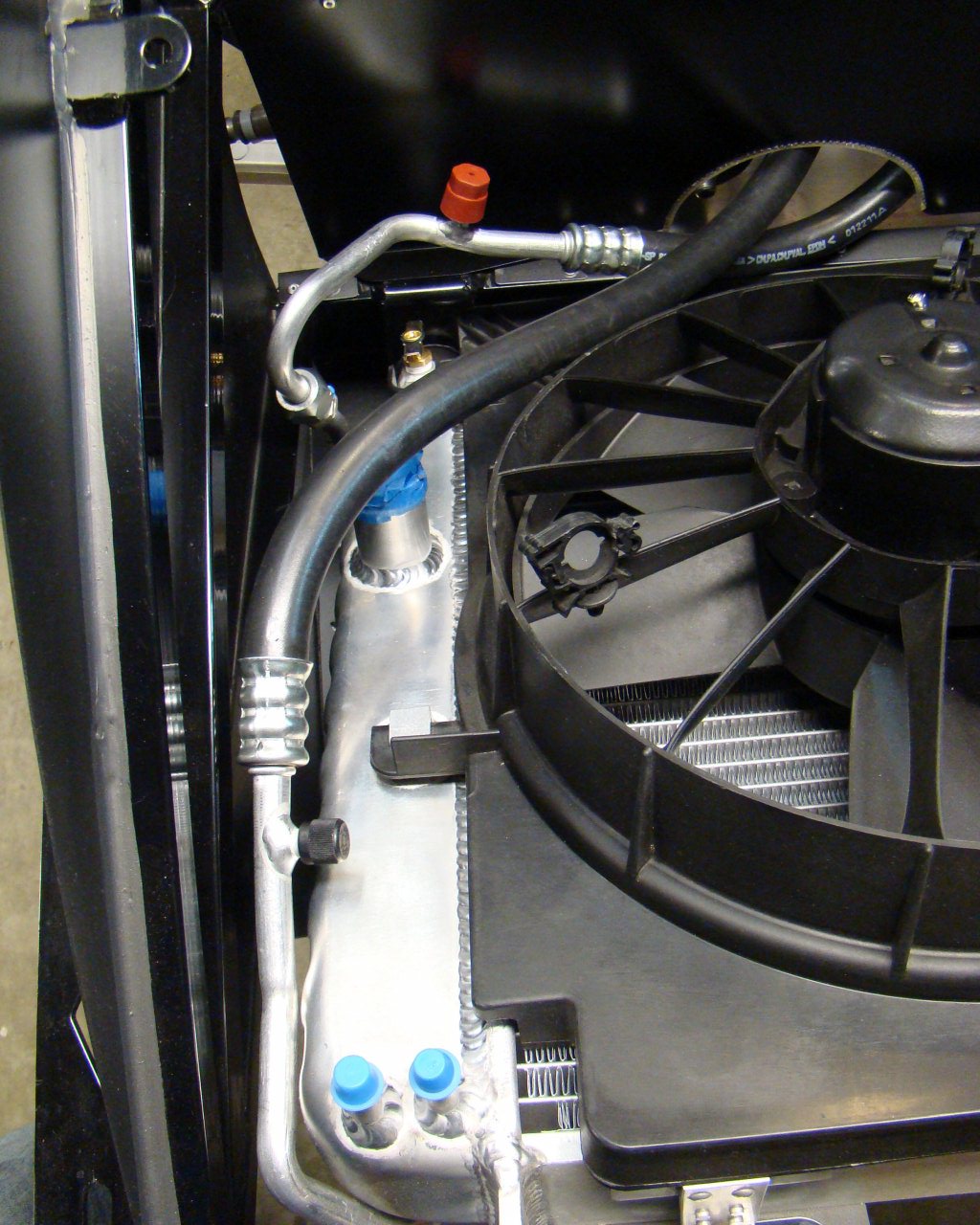

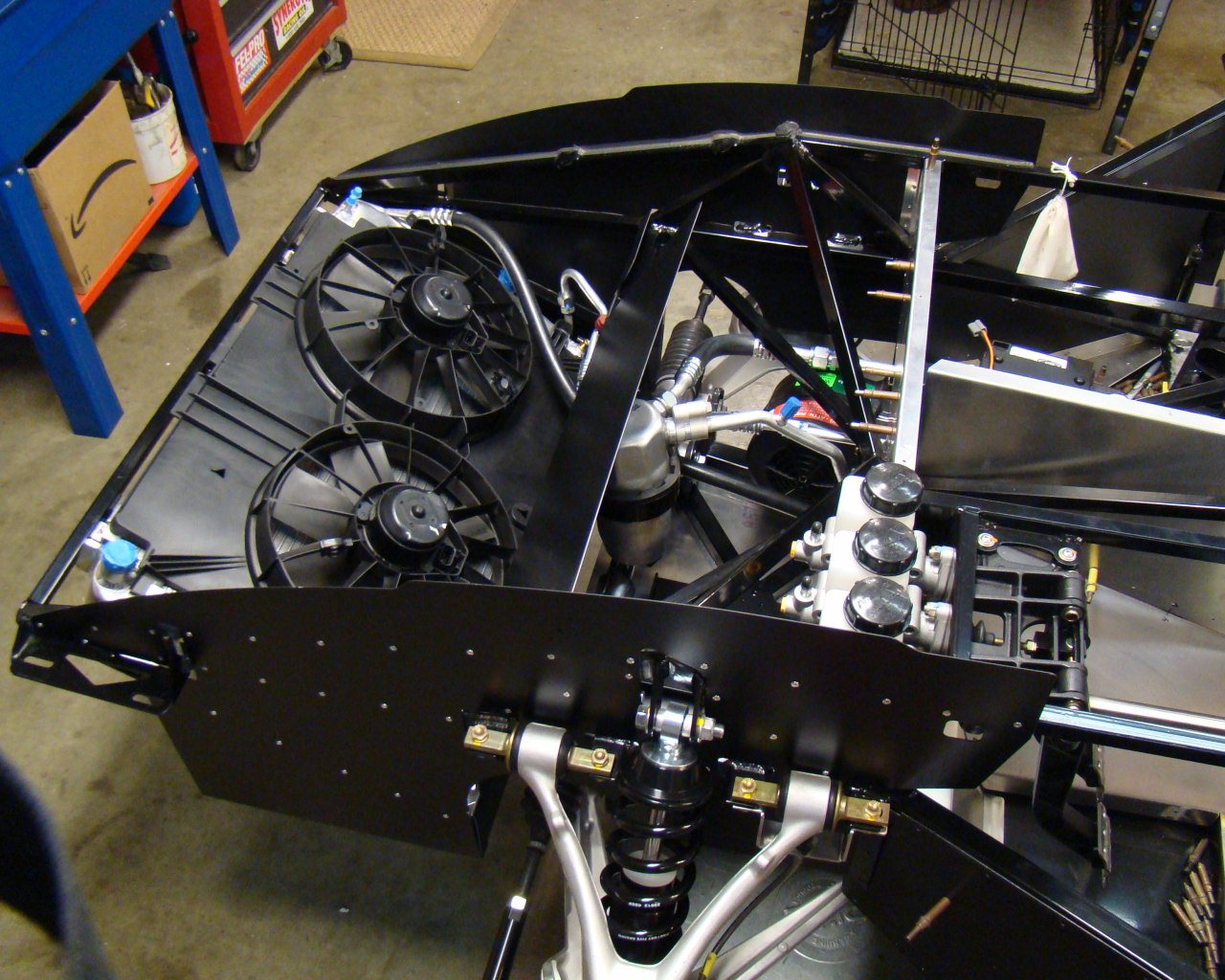

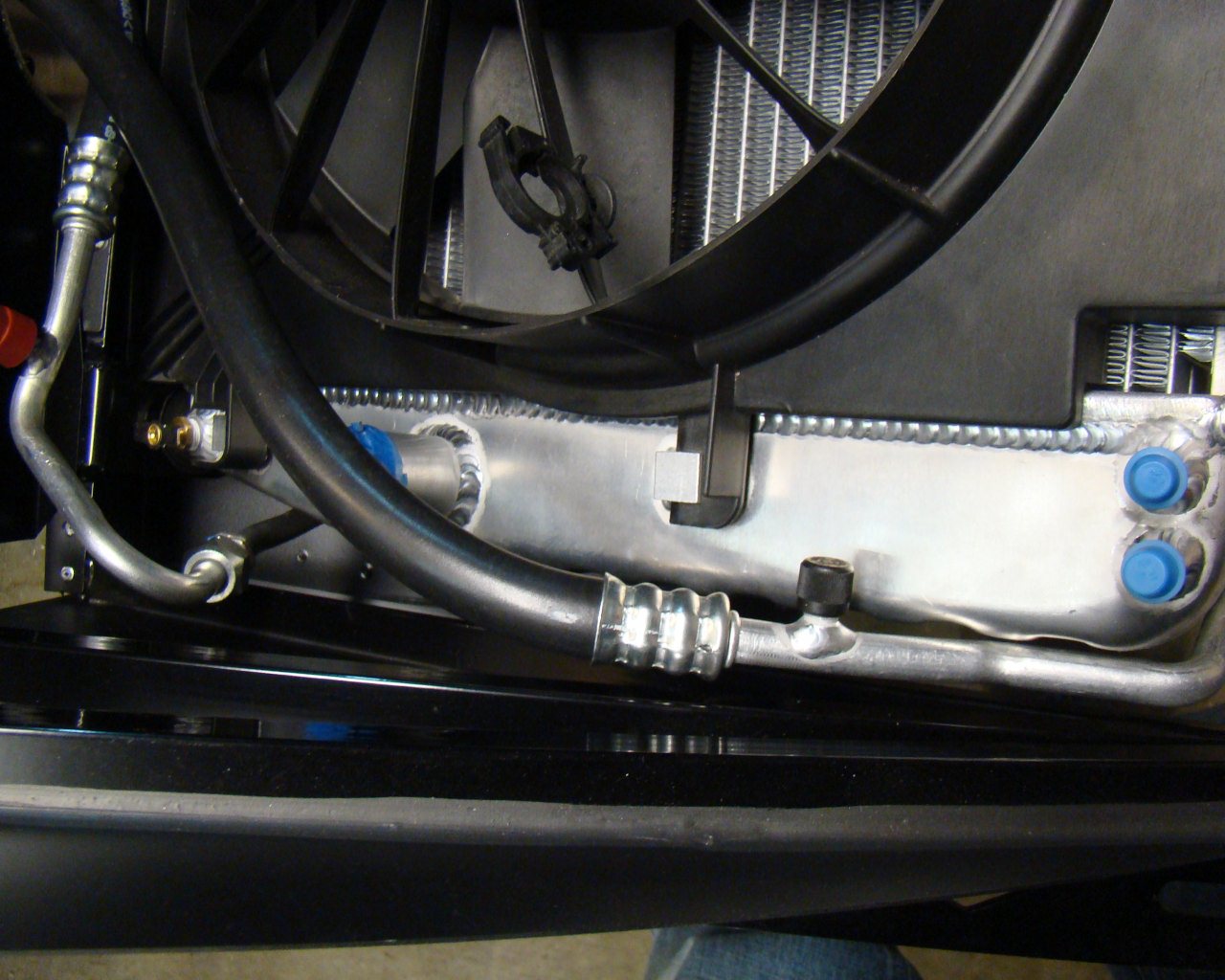

This picture is actually taken after

the lines were connected to the evaporator. A little

manipulation and they fit the dual Dewitts radiator without much

effort. The Dewitts C5 High Performance radiator was a nice

improvement and it didn't take much to make it work. Guys

either TIG weld tabs or you can fabricate clamping brackets made

from aluminum extruded angle riveted back to back as shown in the

cooling section. The Tabs are on the forward GTM frame cross

member. They sit approximately 1/8th inches forward of the

radiator. The fabricated brackets are easily adaptable over a

short distance and provide plenty of rigidity or strength for

holding the radiator in place. The condenser is installed

into the Dewitts tabs until the assembly is fully seated. An

additional "U" channel riveted to an aluminum plate holds the

condensor coil in it's seated position while also interfacing the

tab on the GTM forward cross member tab. Two on the outside for the

radiator and one in the center for the condenser...works

great.

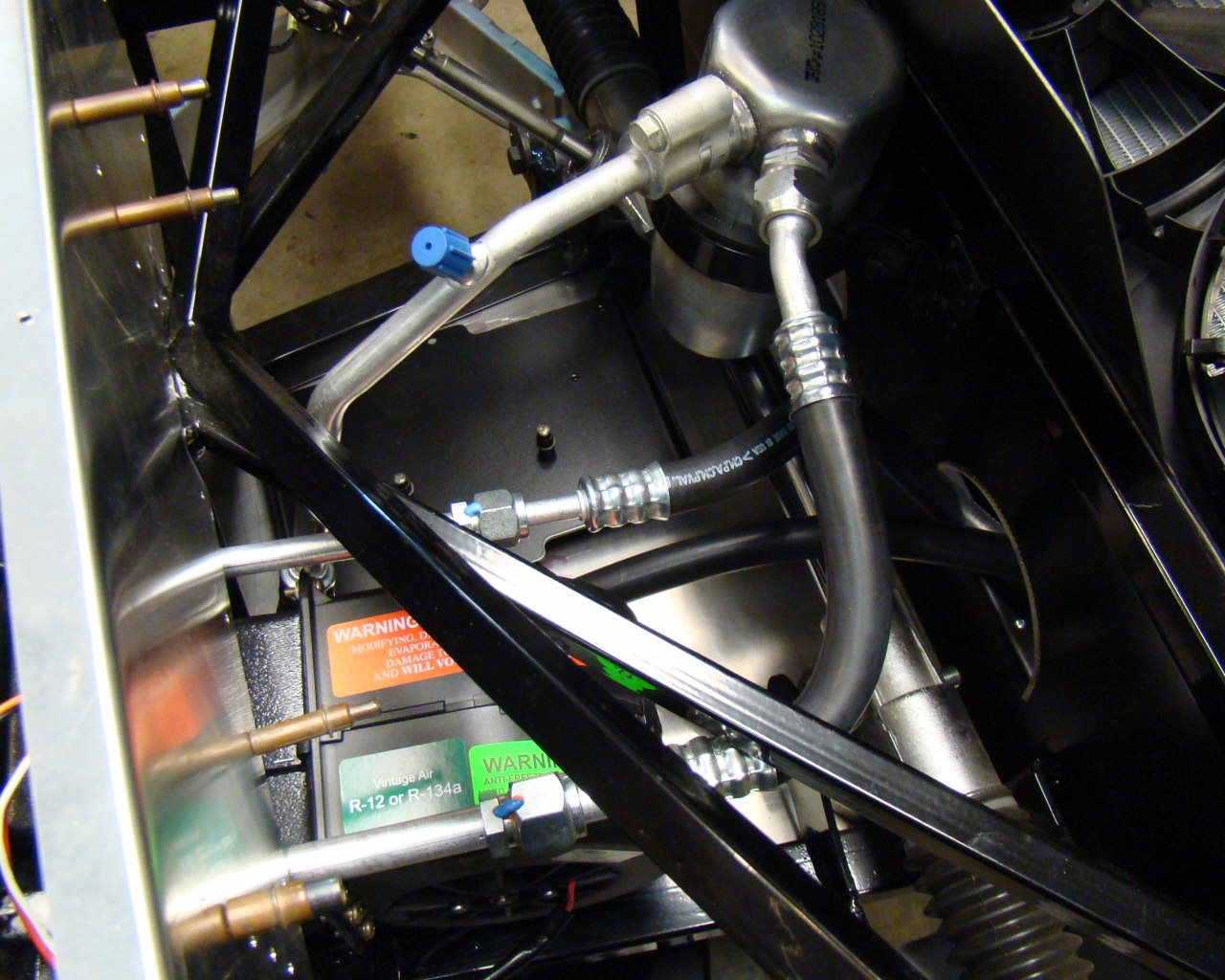

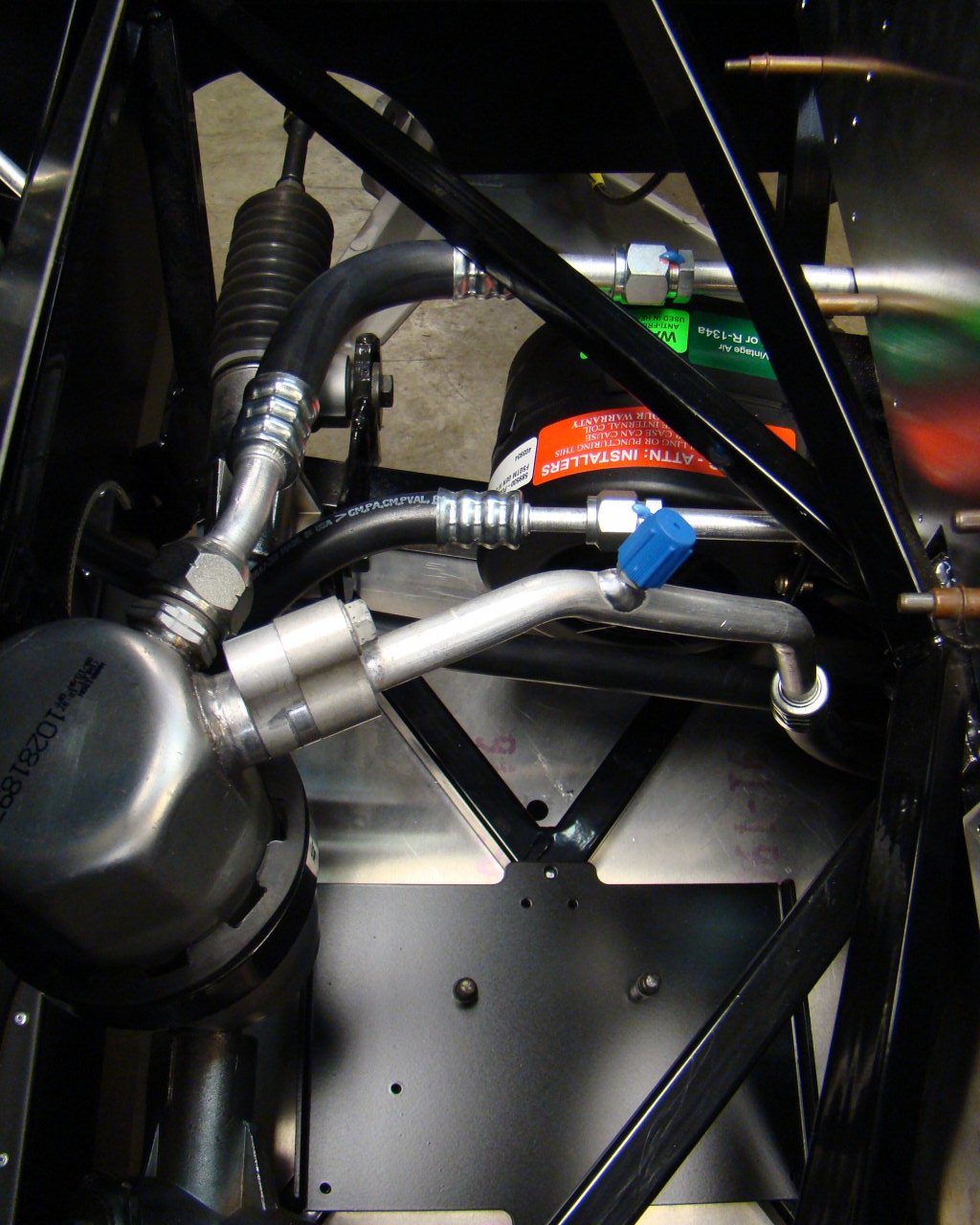

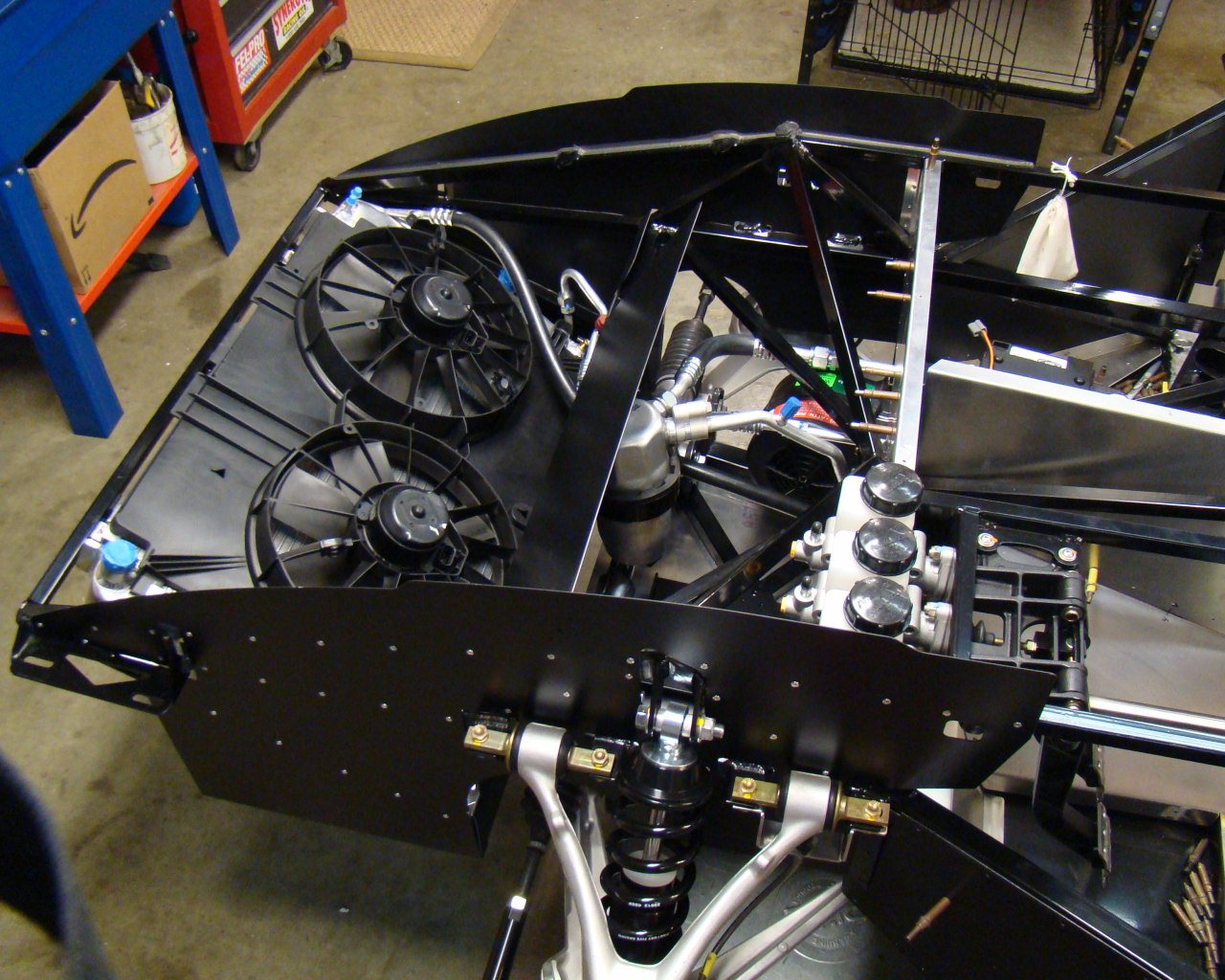

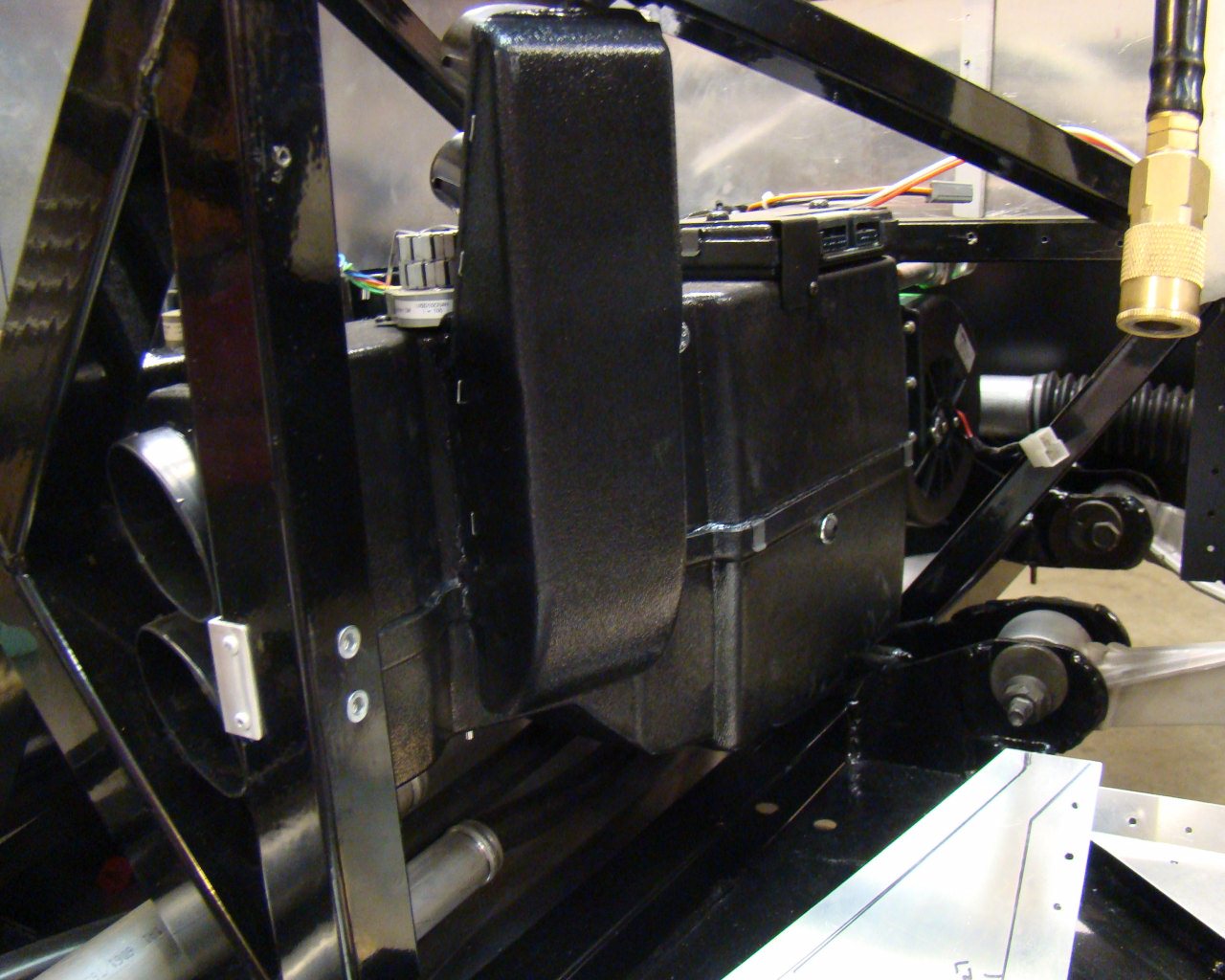

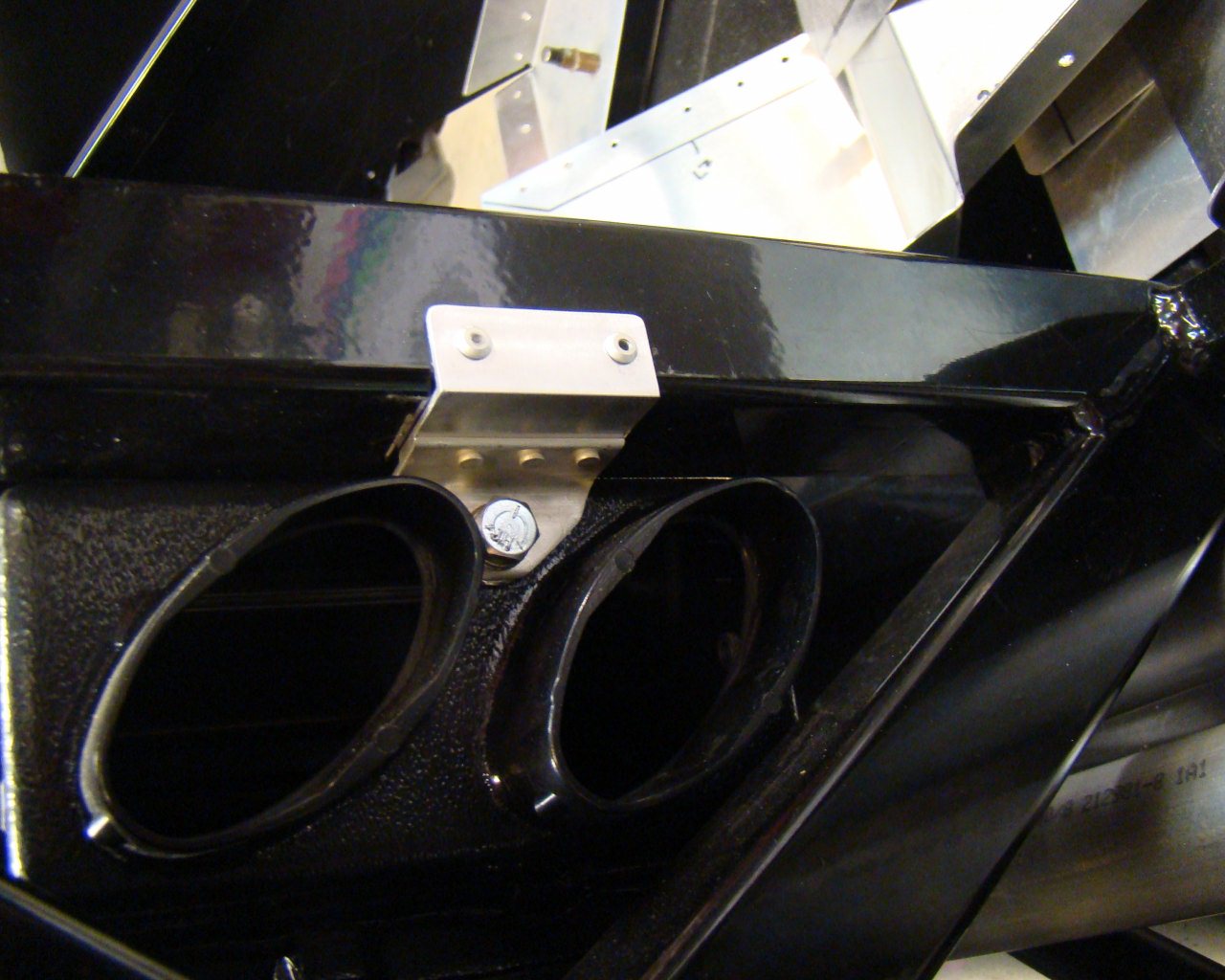

This shows

the basic position of the evaporator assembly. It really

doesn't have much to move once manuevered into position.

Notice the tab fabricated from aluminum angle. This seems to

work better than the steel tab that comes with the kit. For

that one to work, it must be bent or joggled to fit around the

backside of the vertical frame tube. I'm assuming the

aluminum bracket will not interfere with something later. The

bracket can also be seen two pictures below. Even without it, the

unit fits snugly and is held by the forward steel angle bolted to

the intermediate cross member.

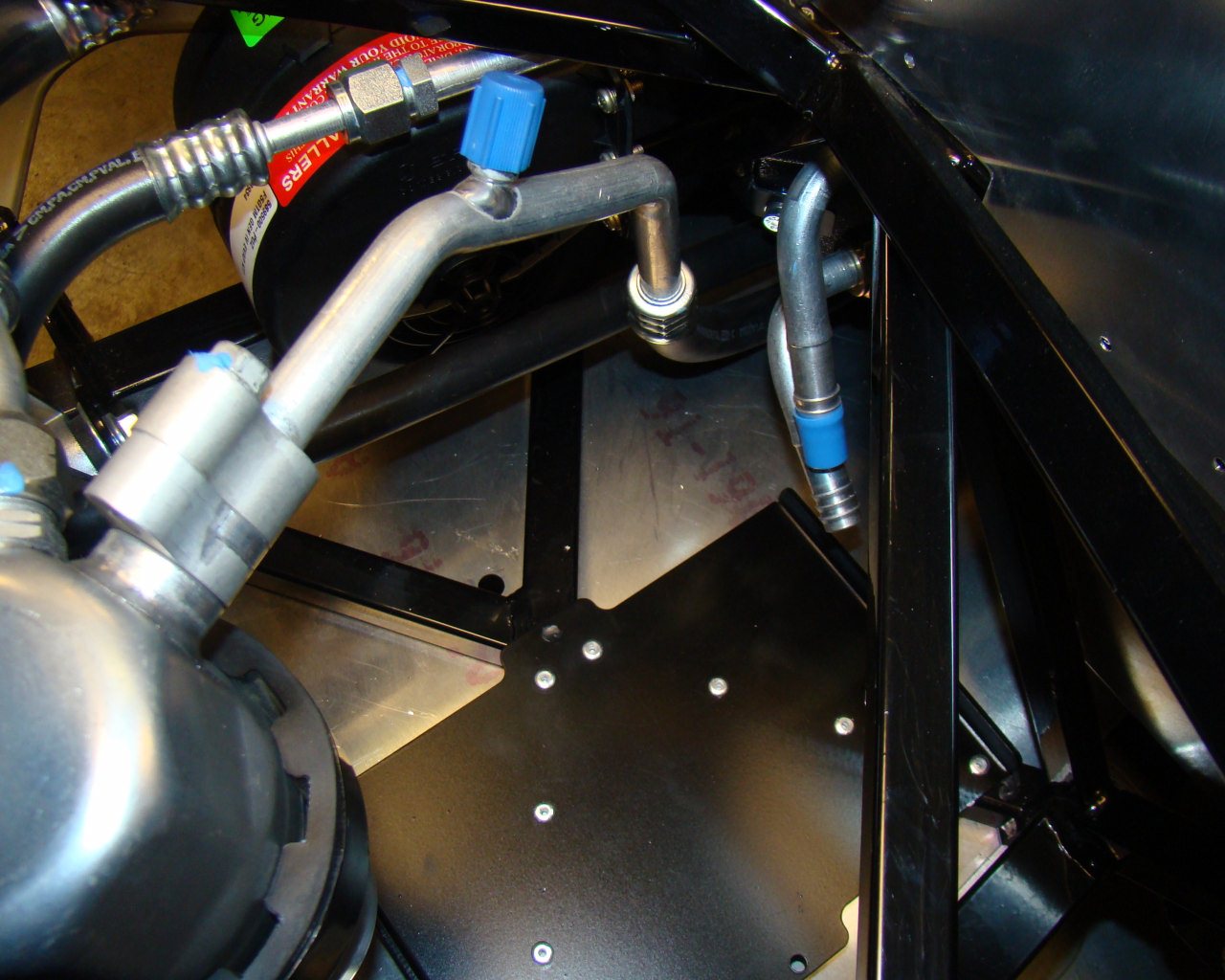

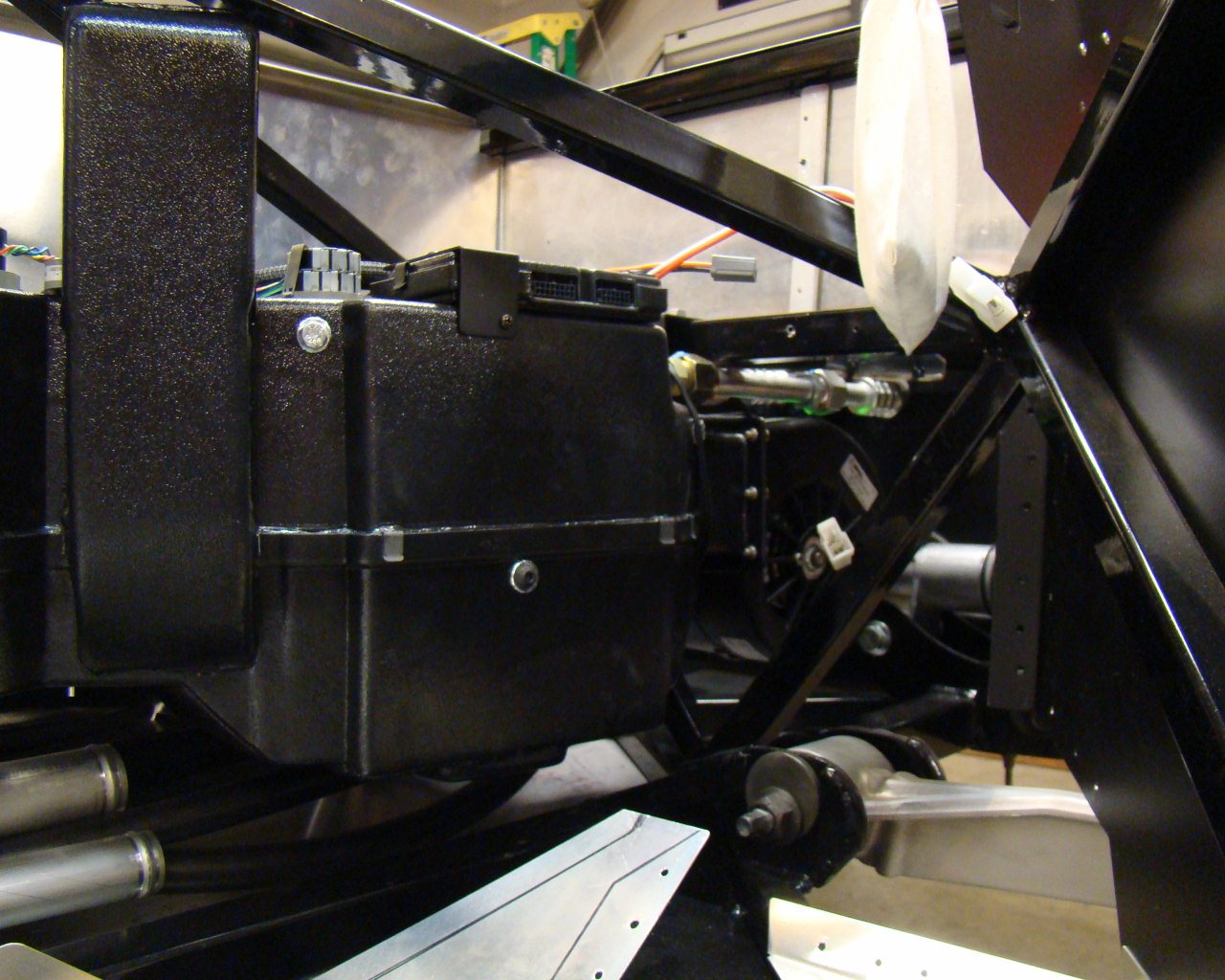

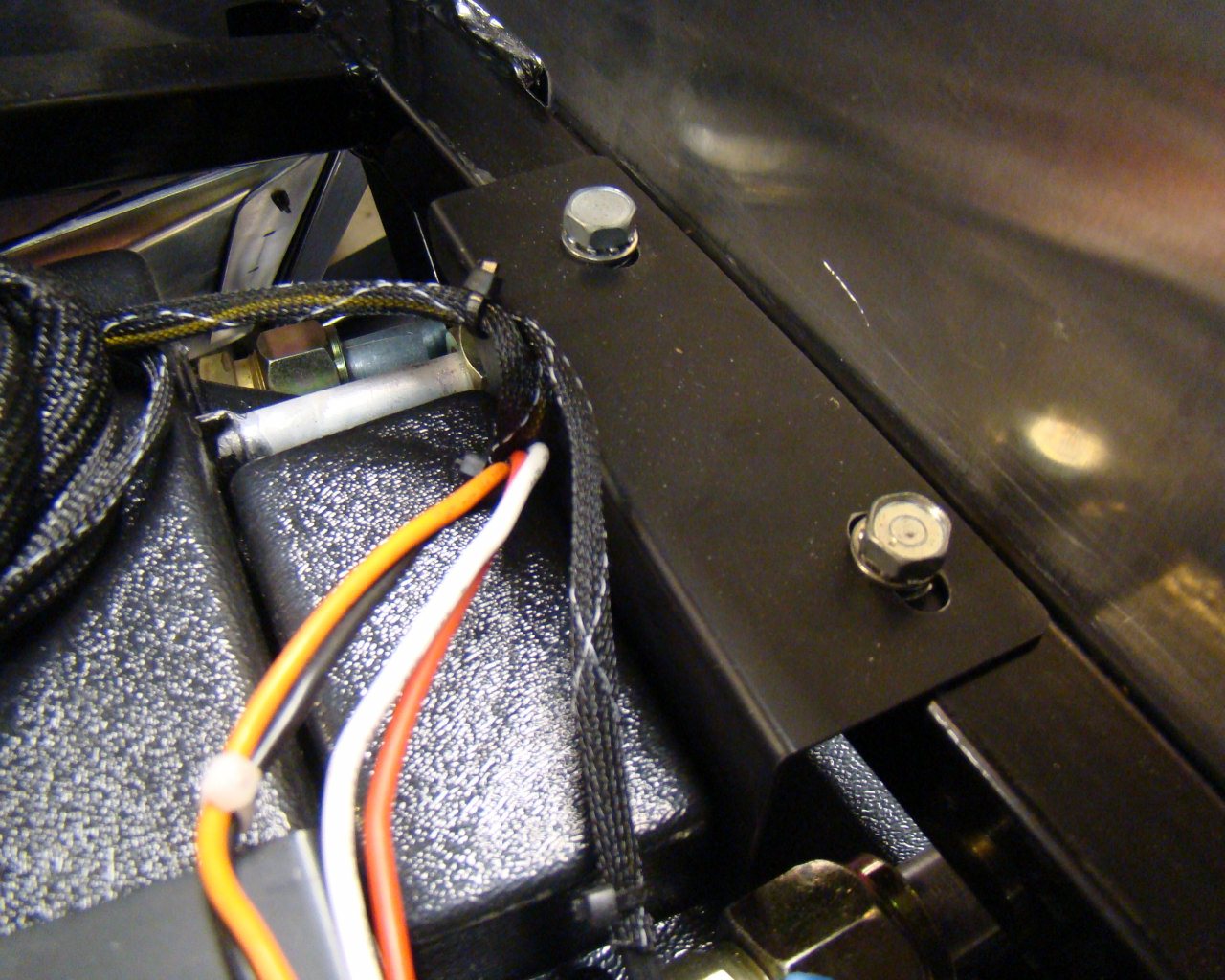

FFR says you

can trim the steel angle but it's a little unclear until you get

the evaporator into position. Once there, the left forward

edge runs into the aluminum panel forward of the angle. I

didn't have to trim this one but it took a slight effort to pull it

back to install the bolt. The rivnuts here are 1/4-20 and the

hole diameter in the frame for this rivnut is 15/64ths. A drill or

reamer slightly over 3/8ths is what this turns out to be. Somewhere

near .380 inches.

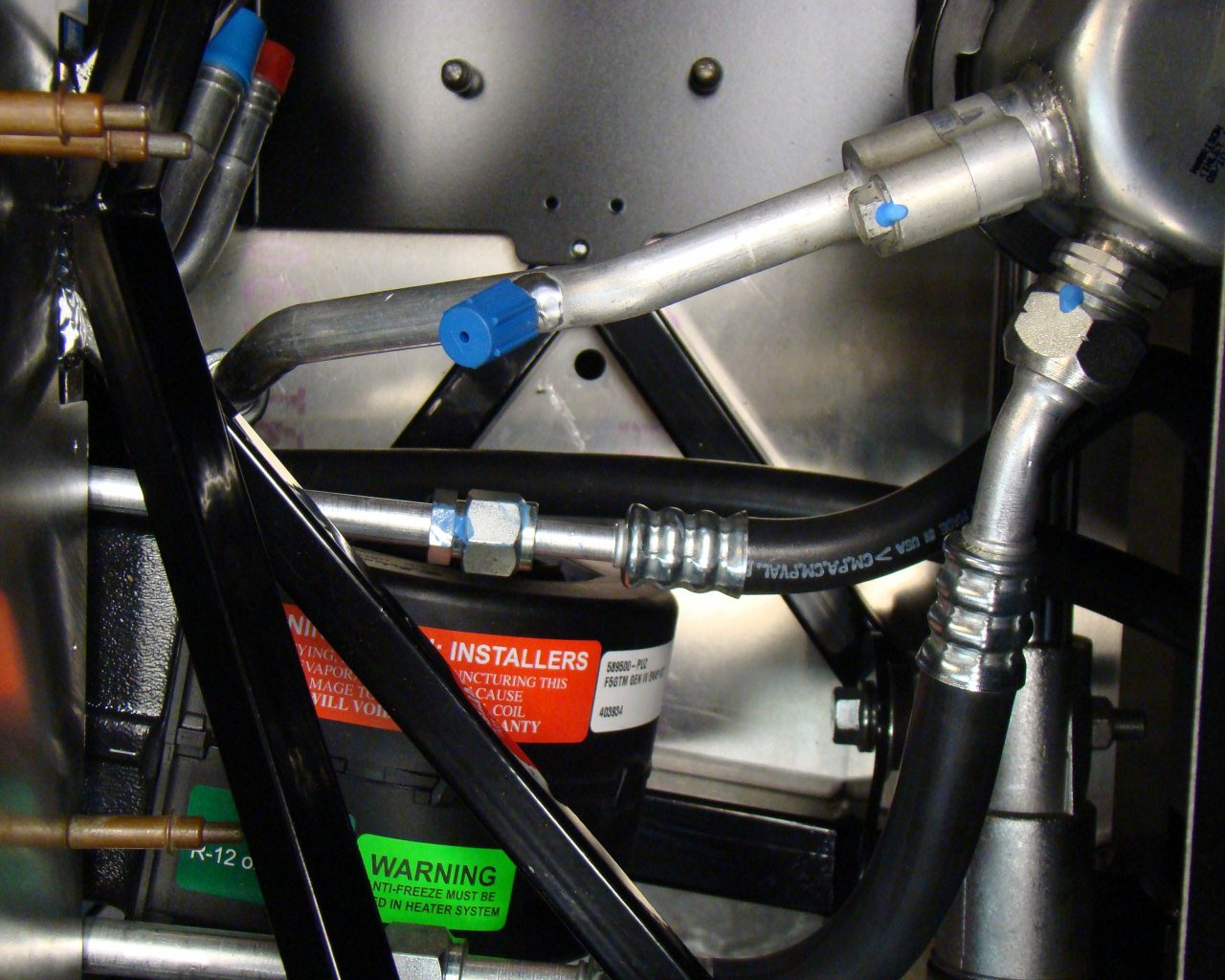

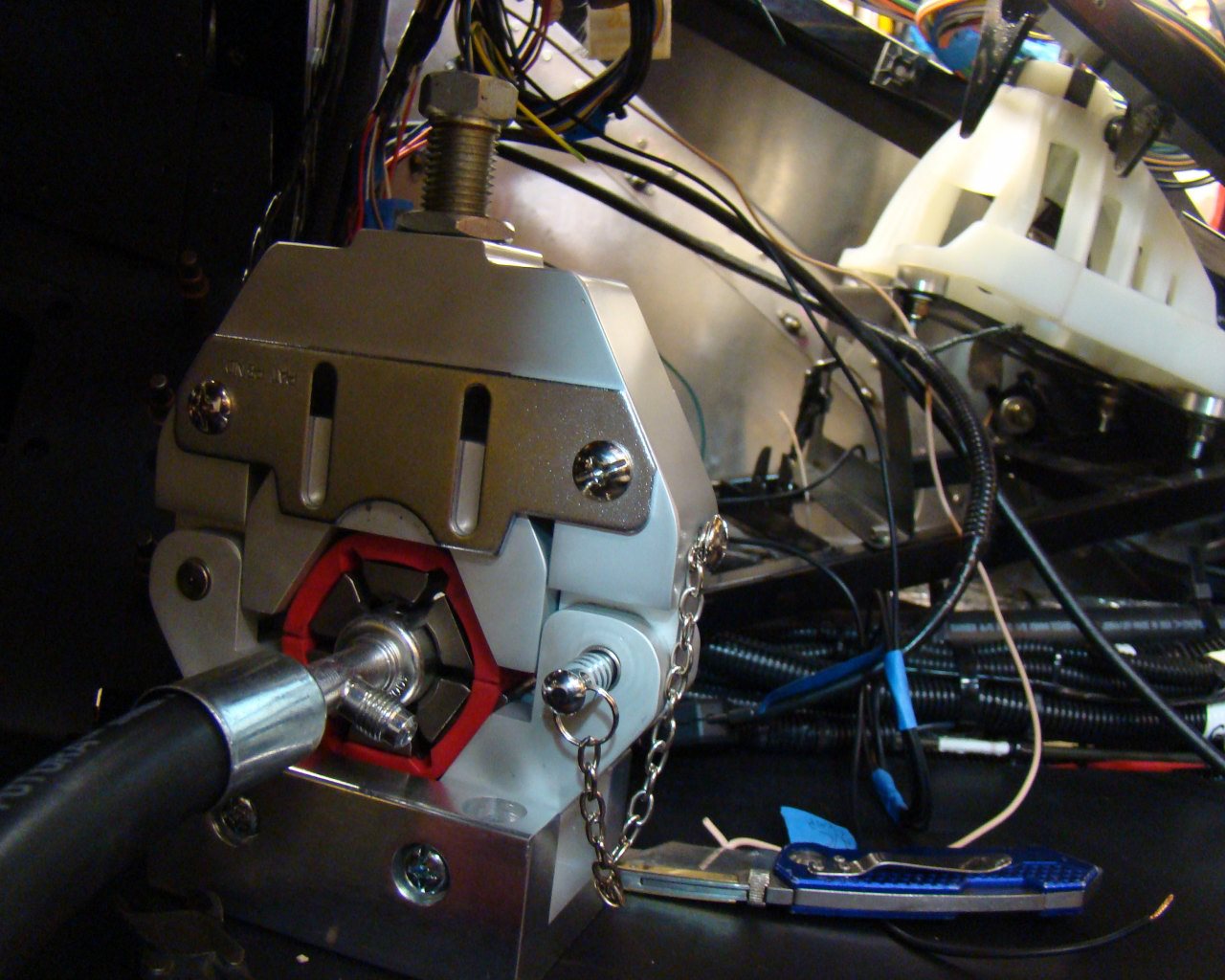

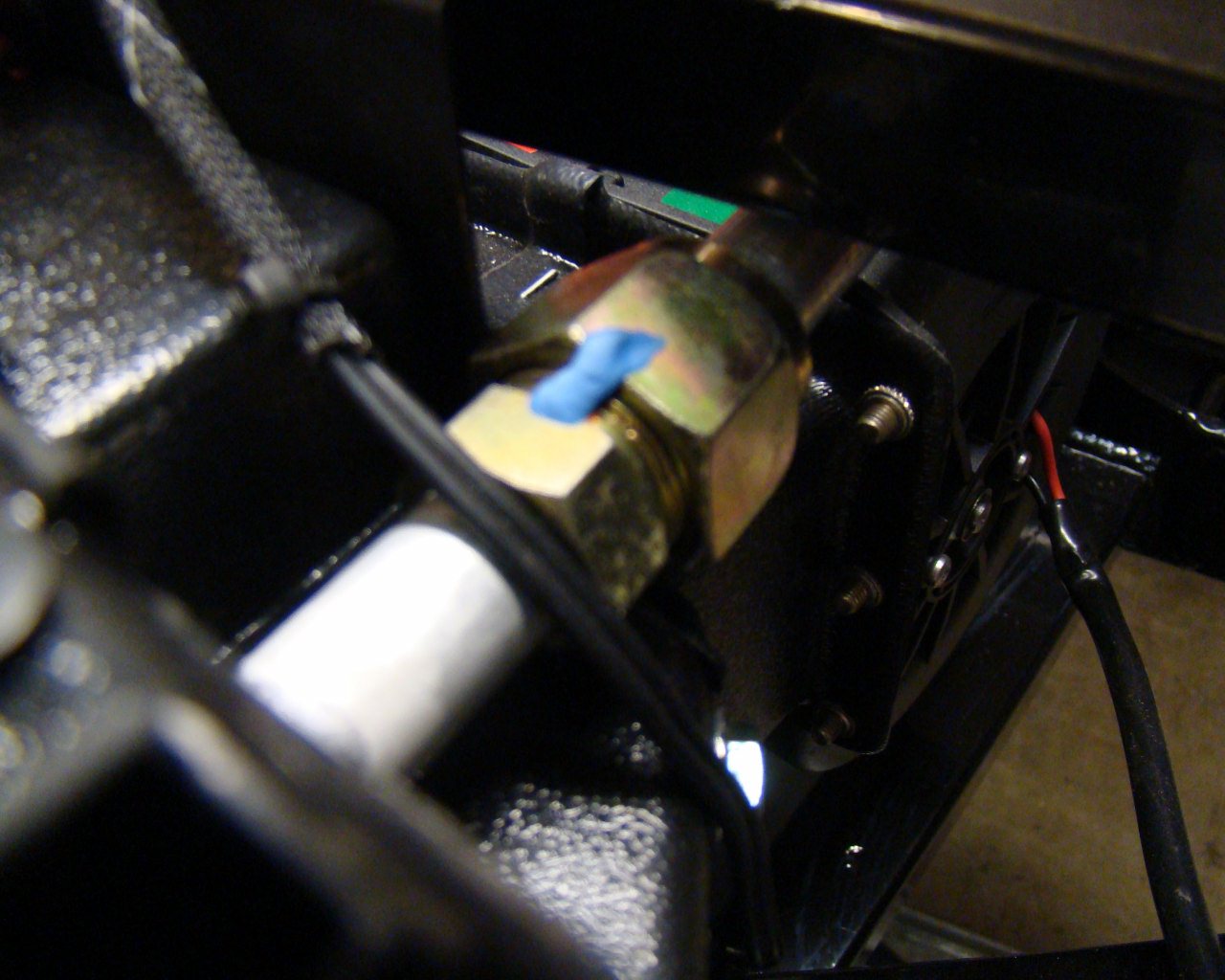

The line

connections are covered by the Vintage Air instructions and are

straight forward. You need to make sure you can get a wrench

on the fittings and that the lines are not hitting the frame.

FFR says you can drop the unit so that the angle resides on the

lower portion of the frame....about an inch lower. This would

not work and it was not necessary on this car. There simply

isn't enough movement available to accomodate accessibility, fit of

the unit in this area and the installation of the forward duct and

blower unit.

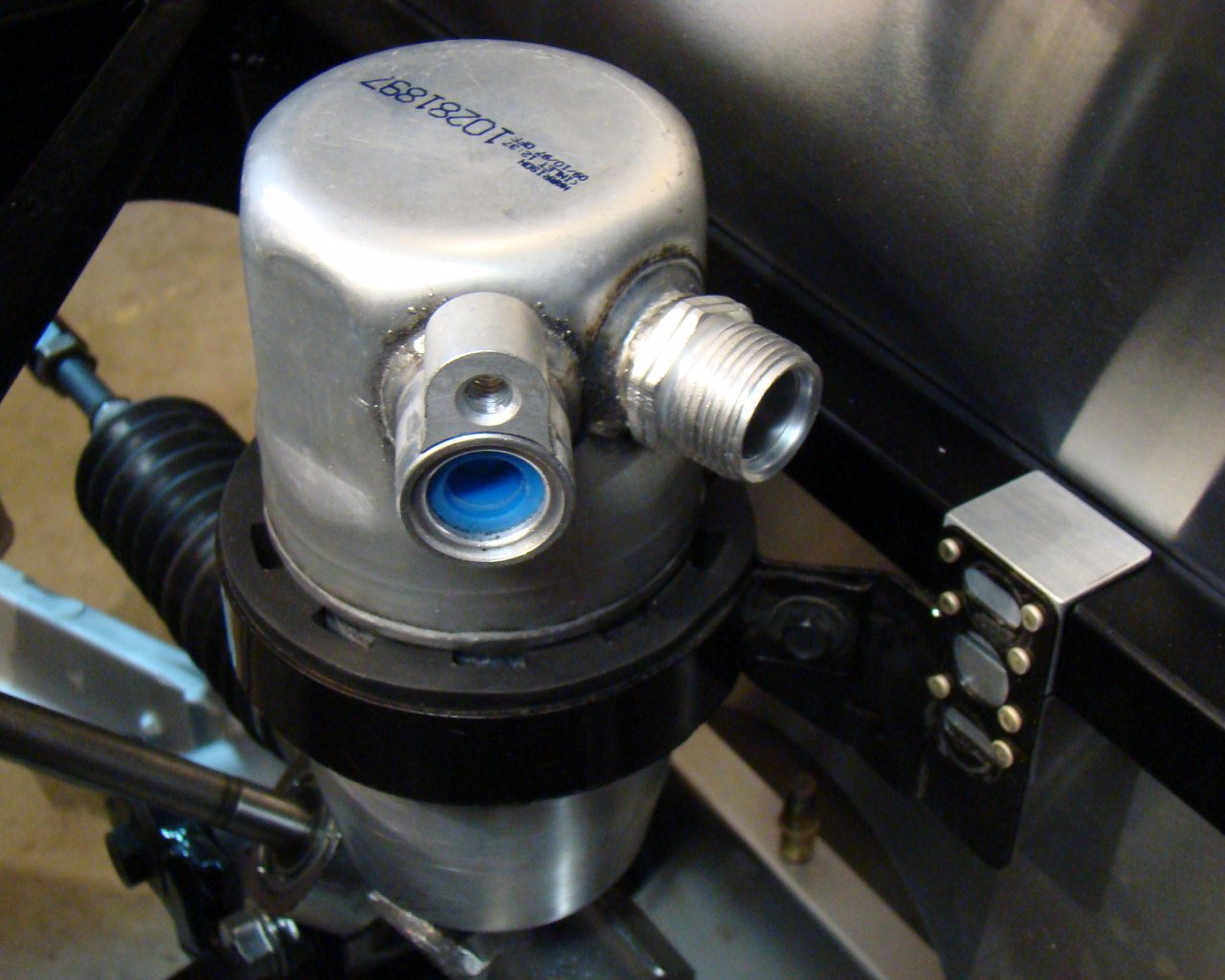

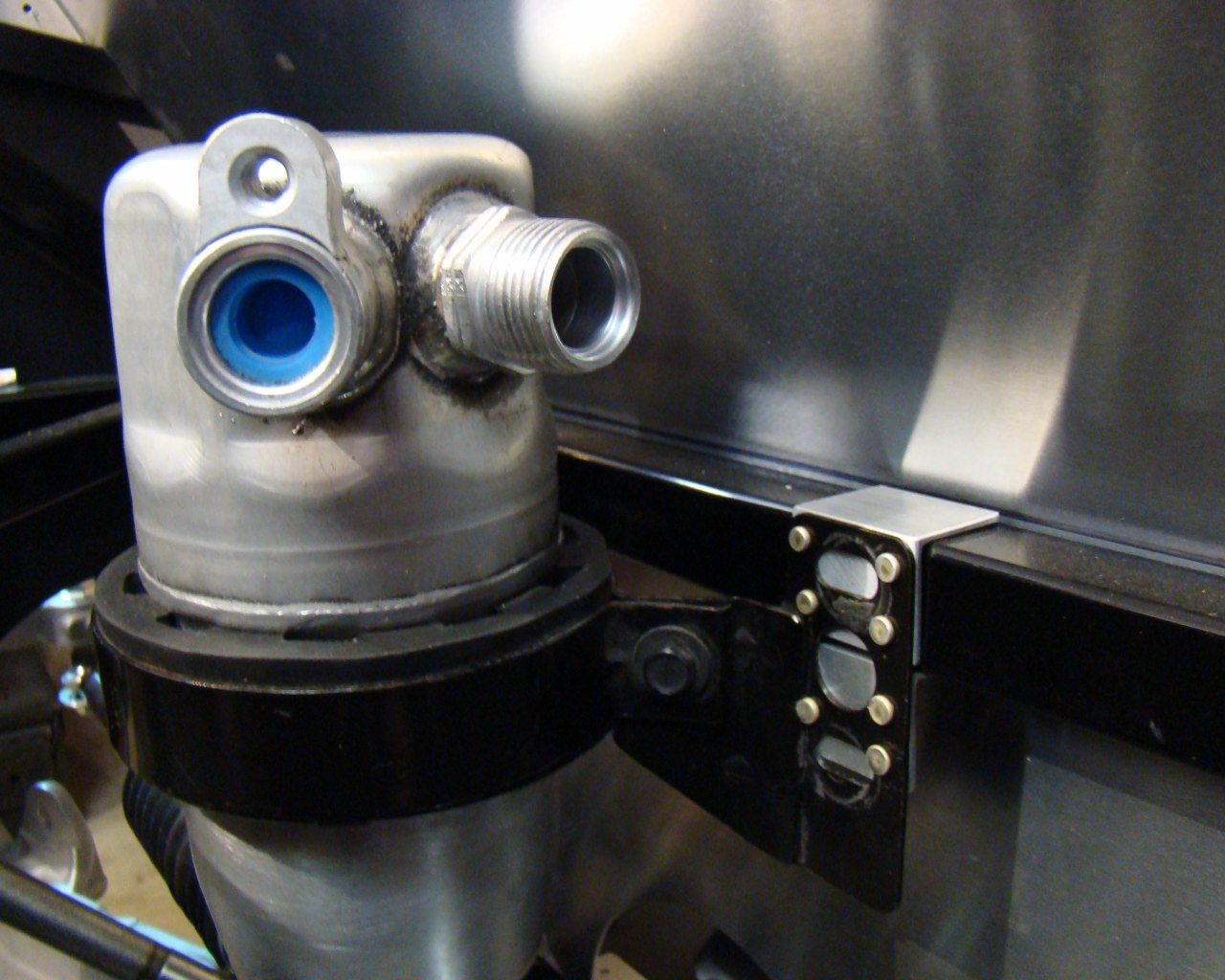

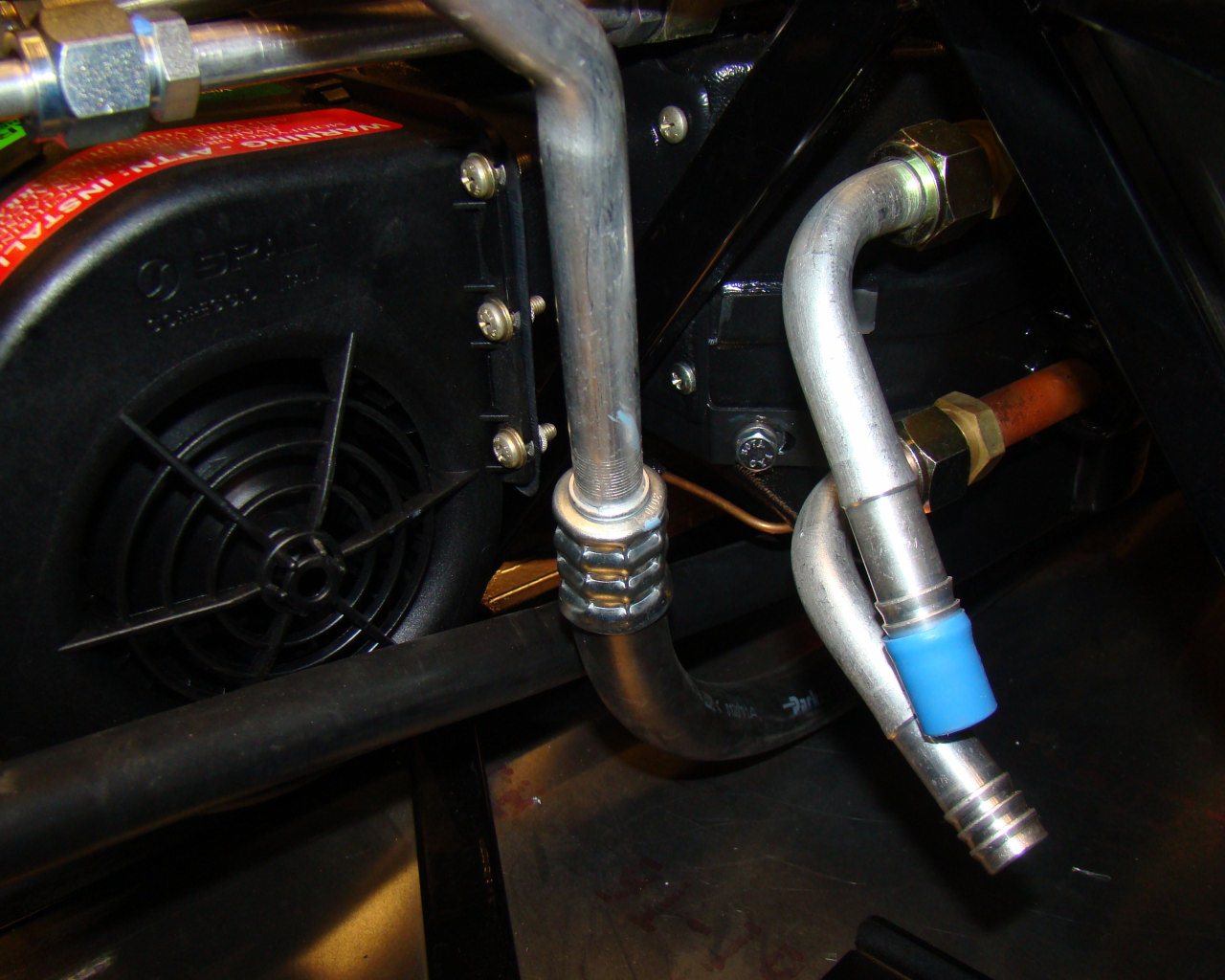

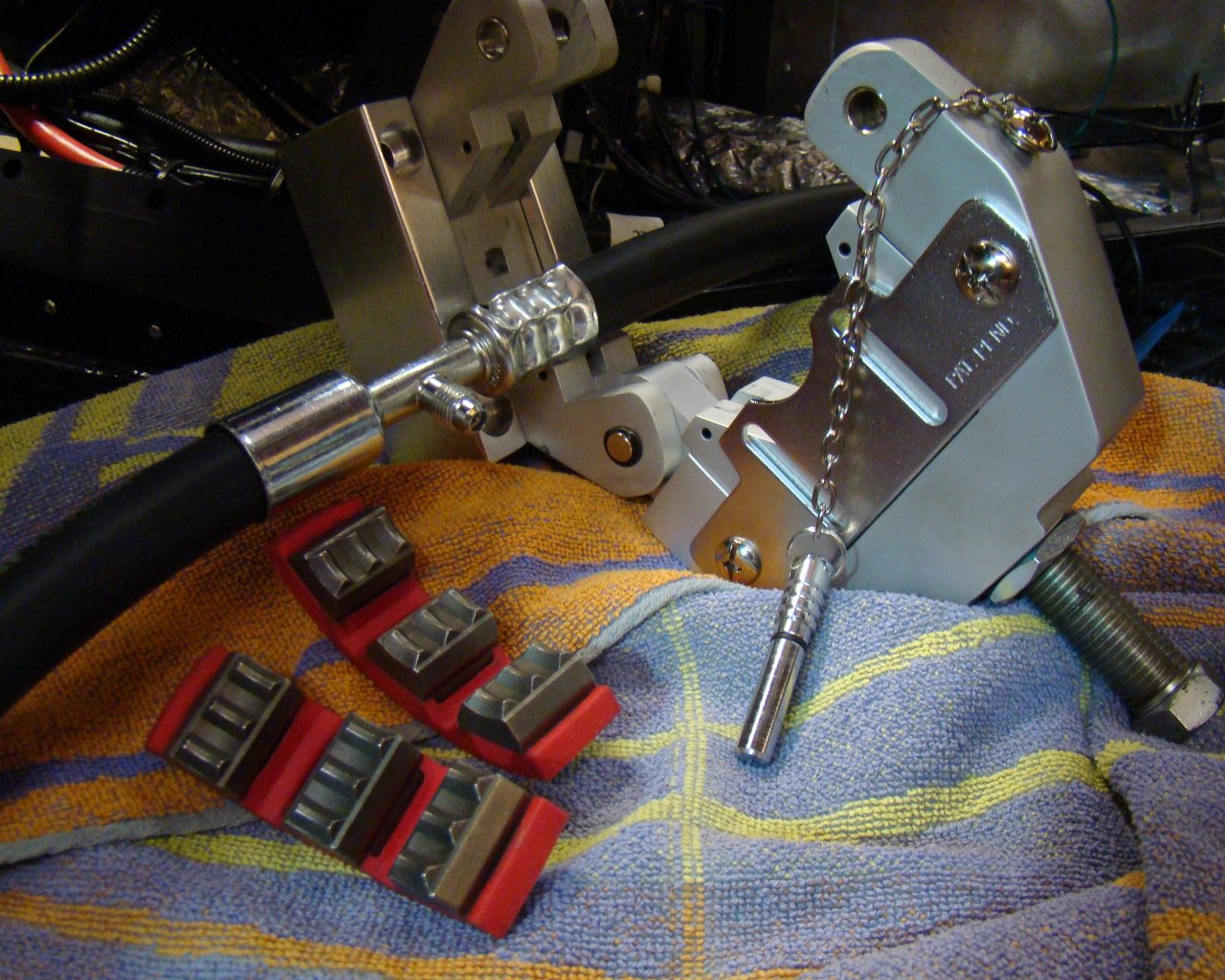

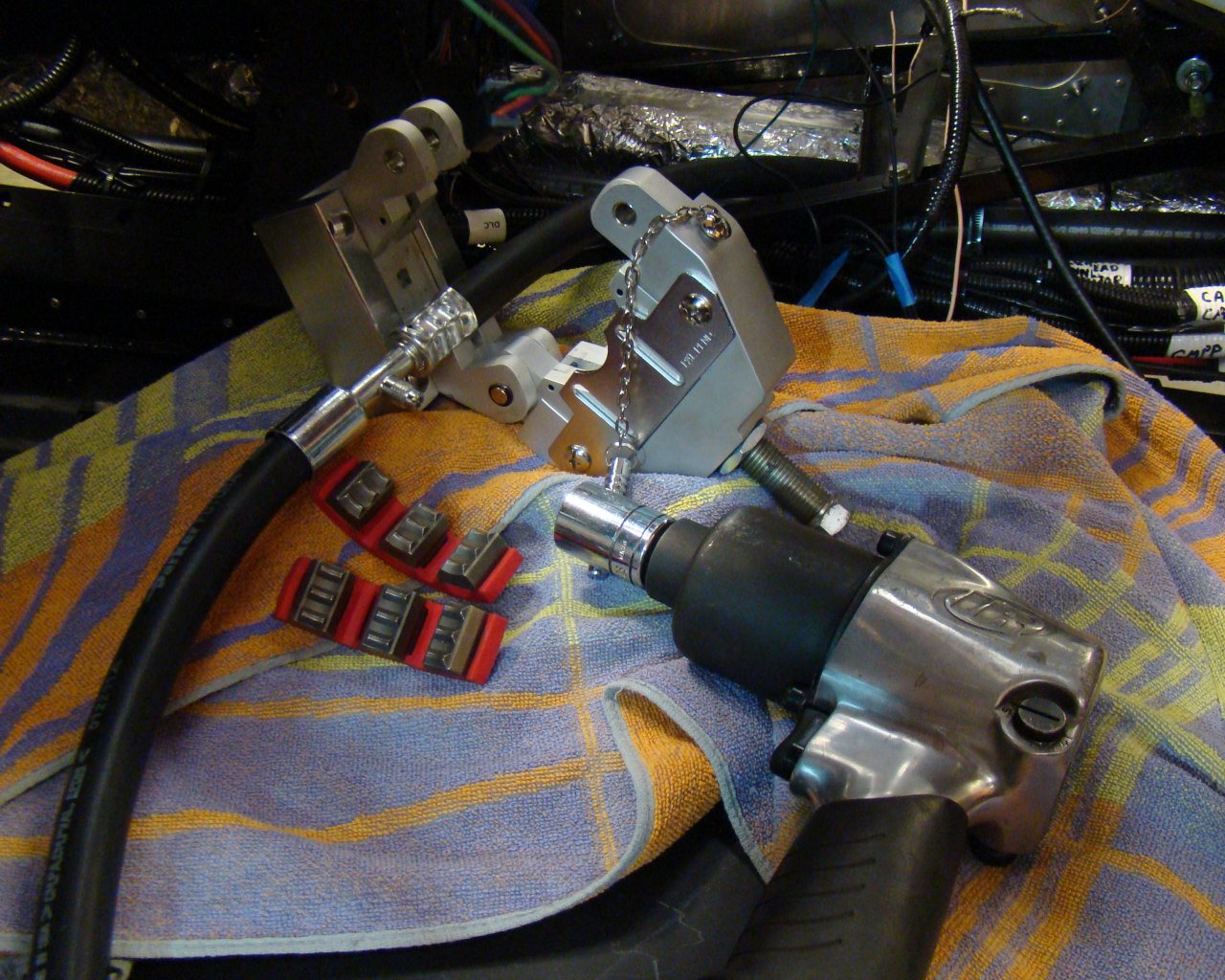

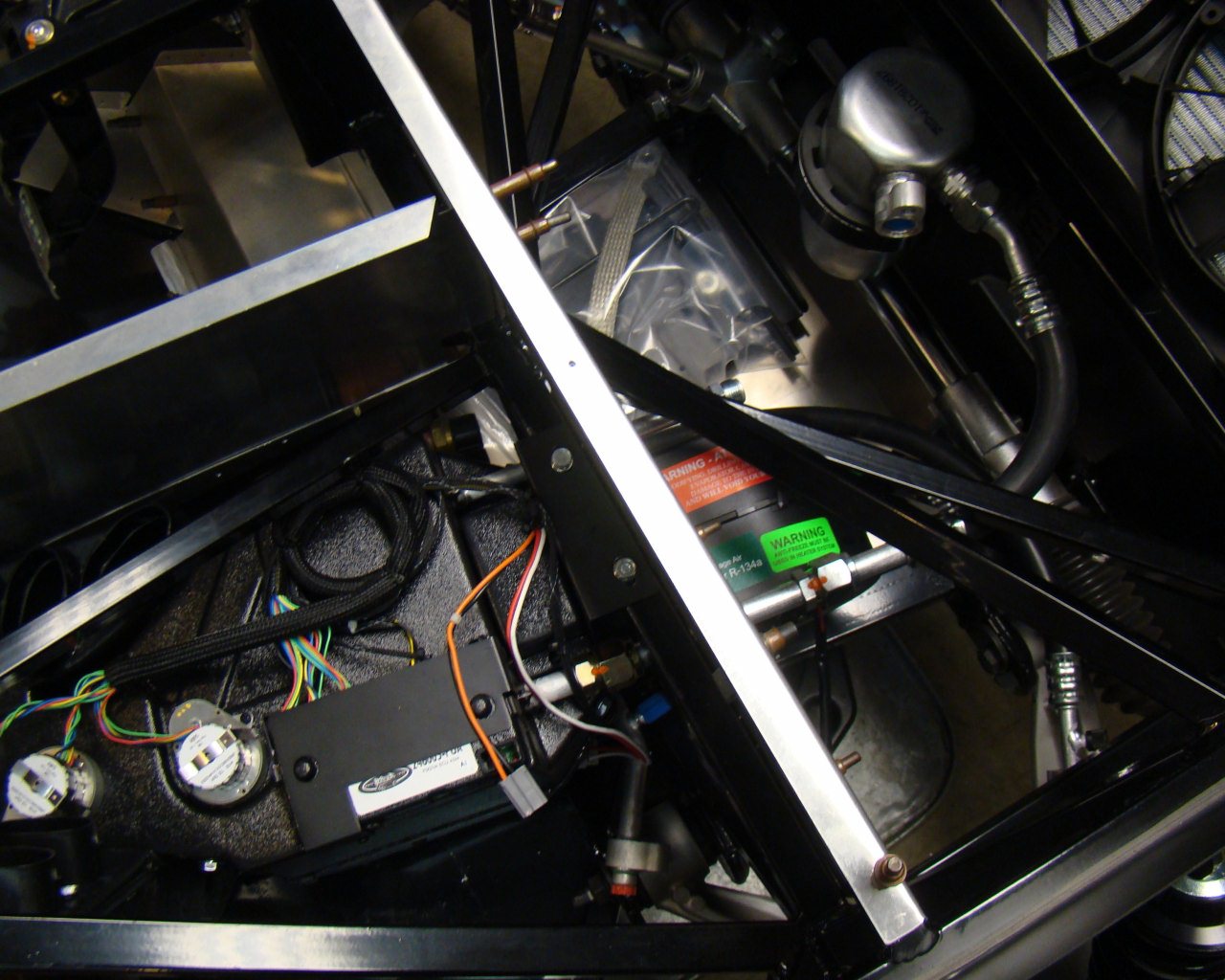

This shows the system components. The dryer was mounted

using a stock Corvette bracket modified with an additional channel

that allowed the unit to be placed on the frame without falling

off. As the hose routing was adjusted, the unit could be slid

left and right but remained in place. When hose routing was

complete, I drilled the hole through the mount and frame.

Although the bolt holds it in place, the added angle spreads the

load and supports the weight and prevents the unit from spinning if

the bolt is loose.