ENGINE

CONTINUE BELOW THE SITE MAP TO SEE ENGINE DESCRIPTION AND

MODIFICATIONS.

SITE MAP:

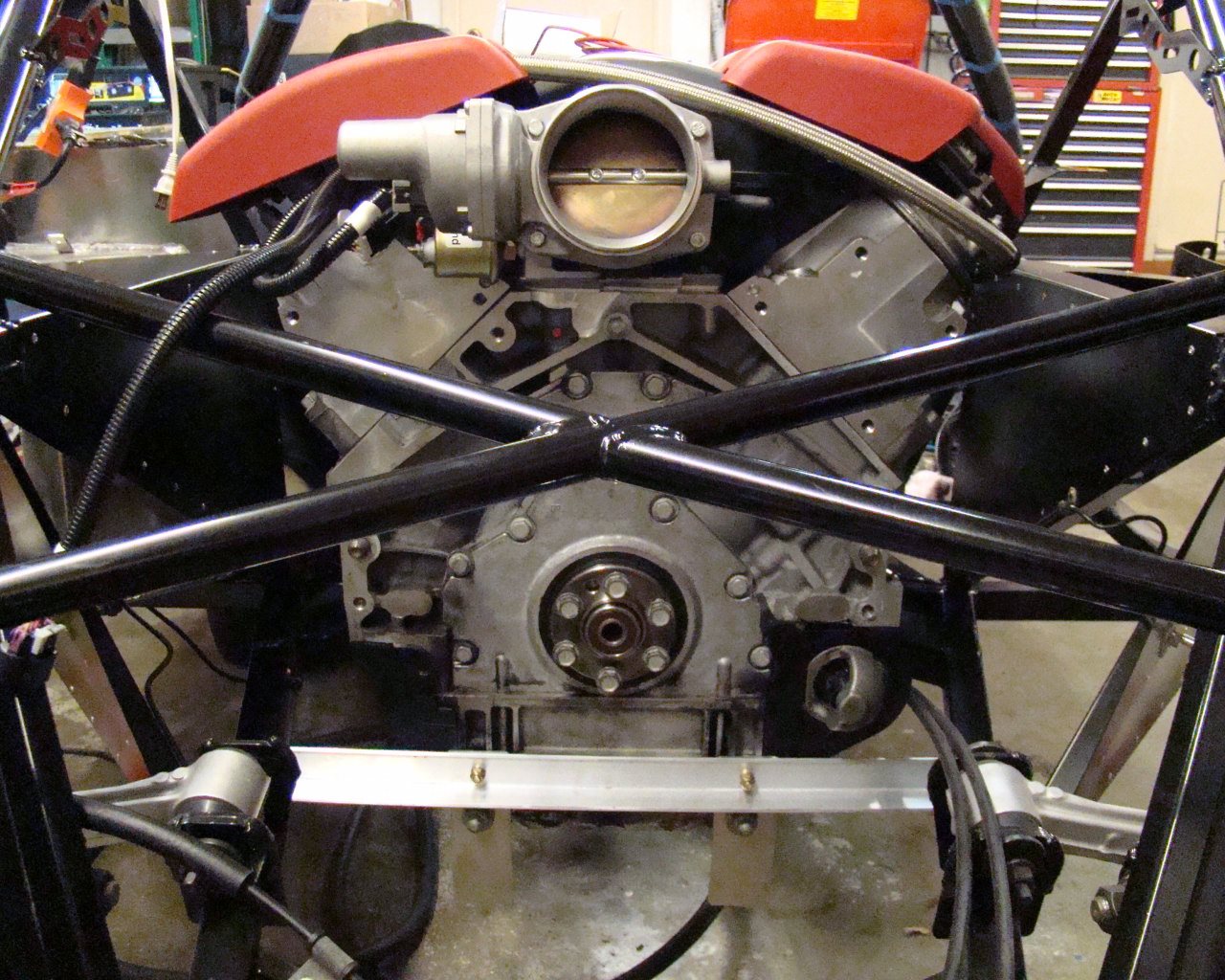

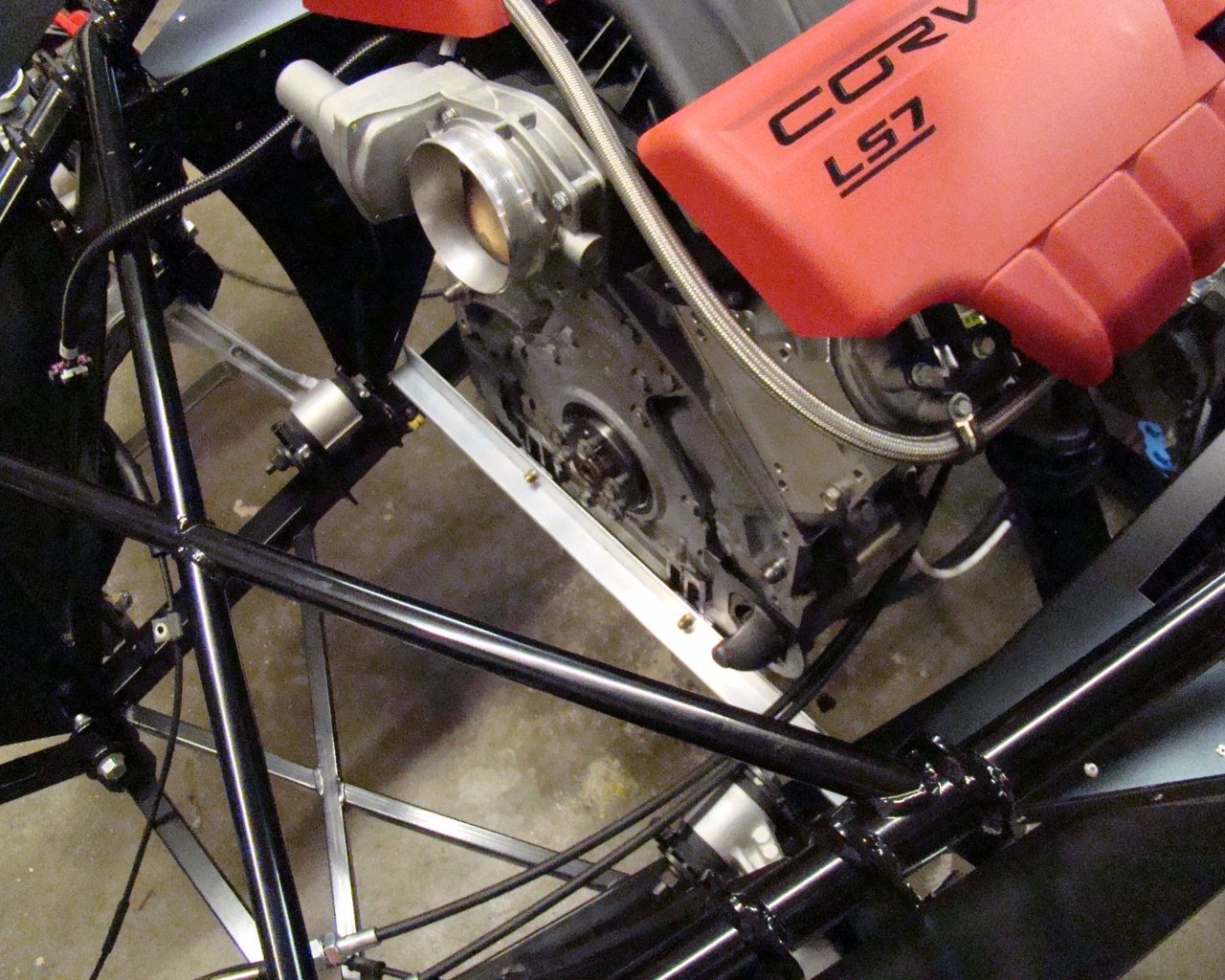

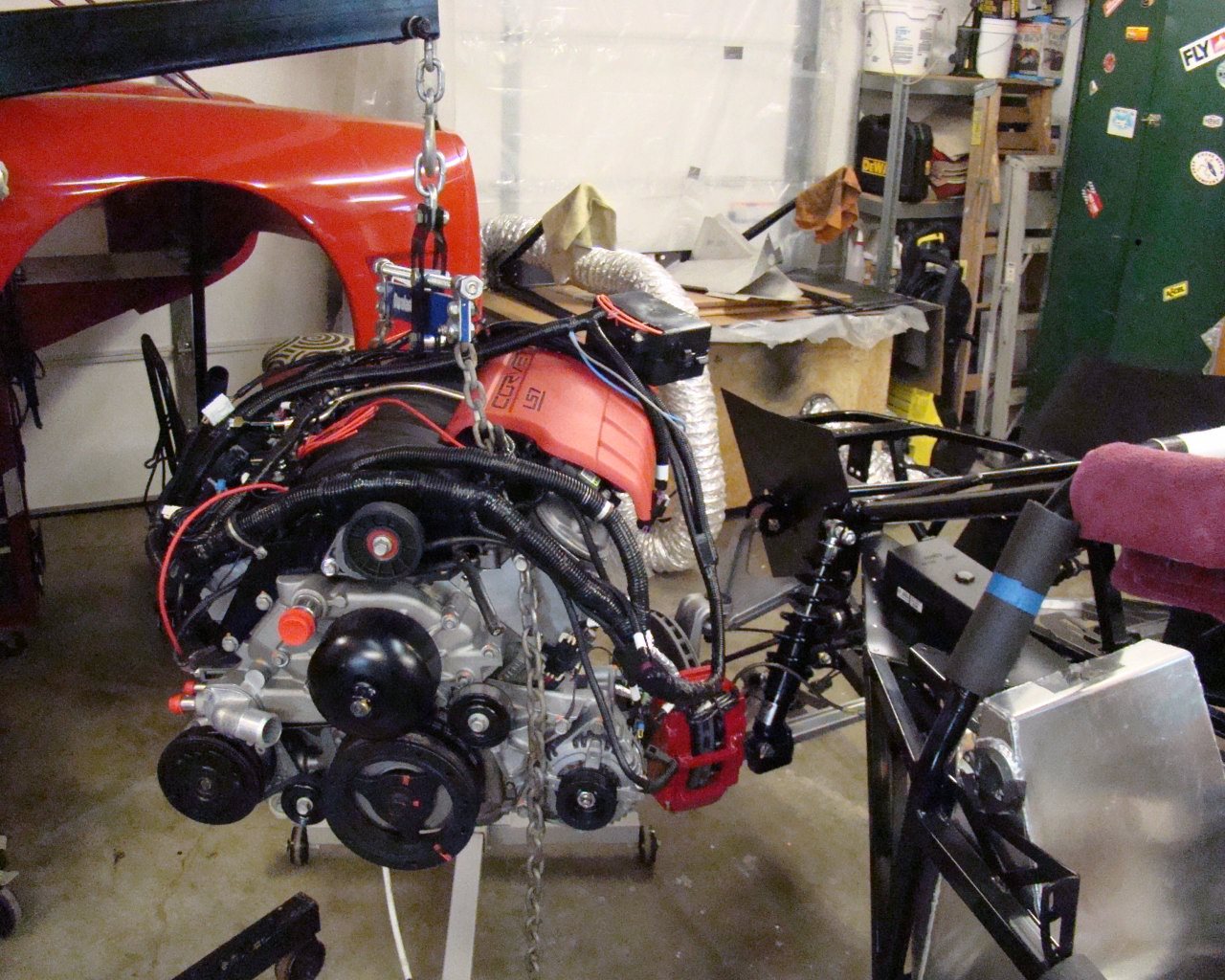

I picked up the engine on Wedsnesday 01/30 after having it shipped from WI. The engine has 12,000 miles on it and came from a salvaged Z06 from California. This particular engine has a similar setup to the 660 HP Lingenfelter package with CAM, CNC ported heads, stainless valves and matched intake. The work was performed by RPM motors in Santa Clarita CA. Based on the documentation, the engine produces 570 HP at the wheels on the Dyno. The above video (to the left) is the engine running prior to being pulled and shipped. To the right is what it looks like in a GTM.

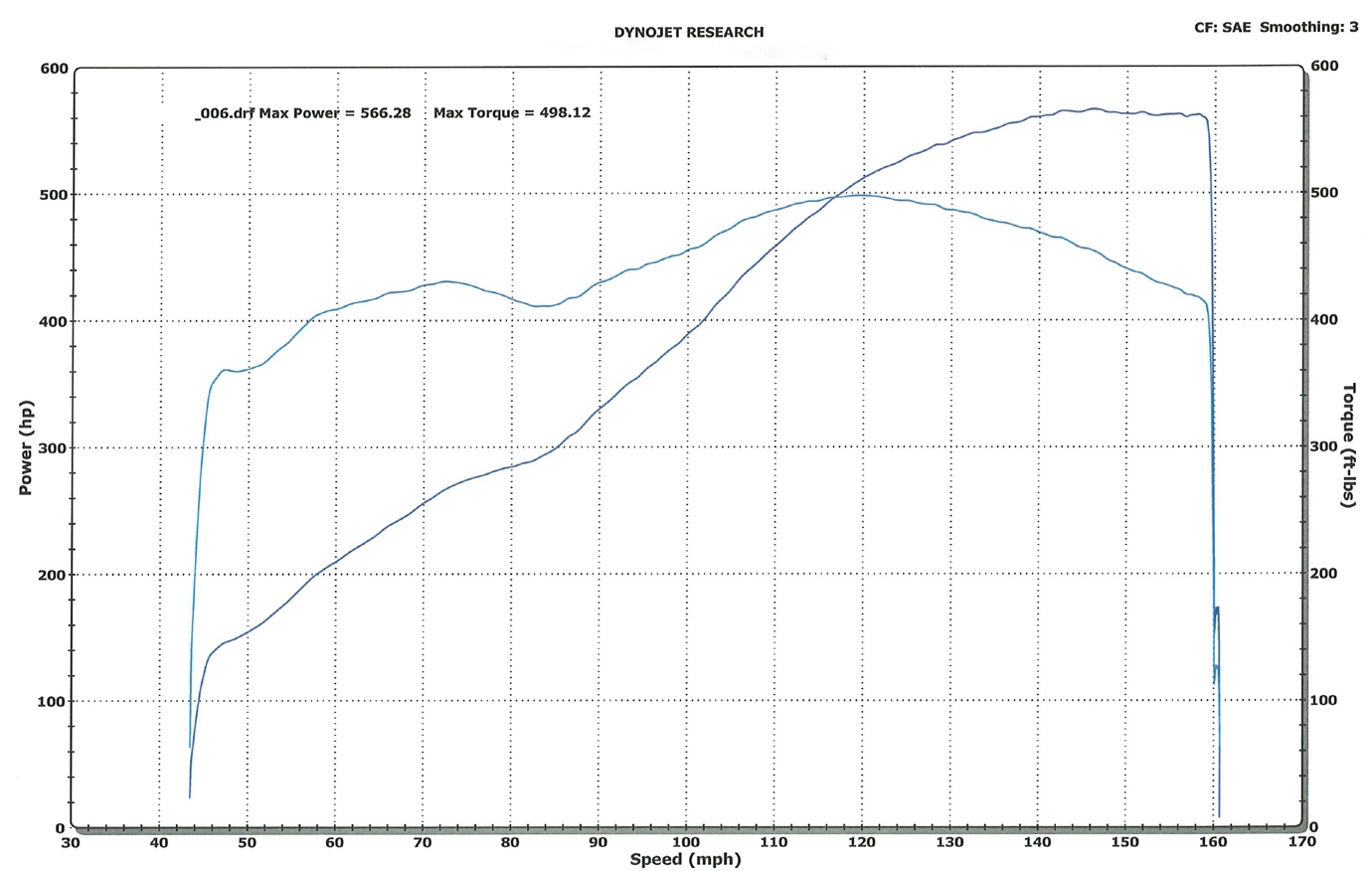

I inserted a Dyno sheet for this setup for informational purposes. This is at the rear wheels. For those confused, HP is measured in two ways. One is on a stand with almost nothing connected. The other is when the engine is installed in a car with all the accesories and drive train connected. It can be impressive to advertise 660 HP in a car. Real power is what you get at the wheels. In this case, a 660 HP engine delivers just short of 570 HP @ 500 FT/LB Torque at the wheels. The rest is used to get it there (the drive shaft, axles etc)while keeping you comfortable in the process (i.e., stereo, lights, coffee warmer etc).

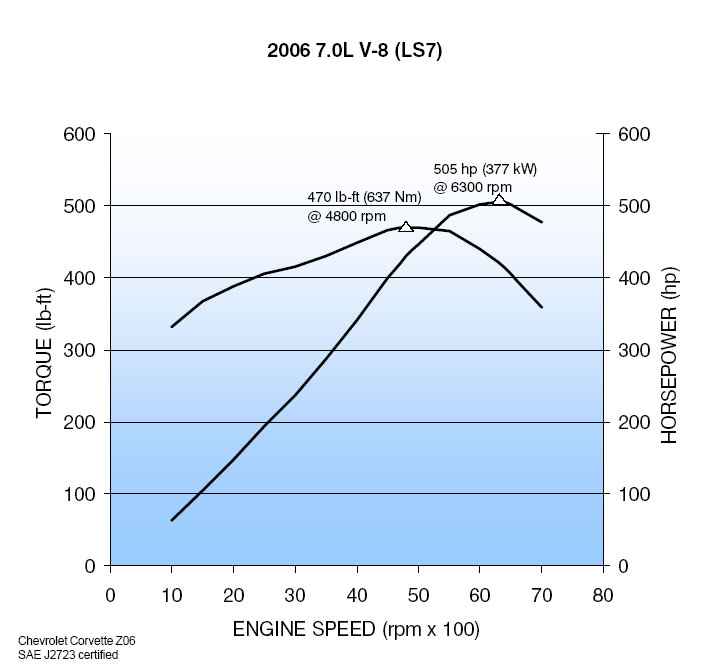

For

comparison, the stock Z06 Dyno and spec sheet are shown

below.

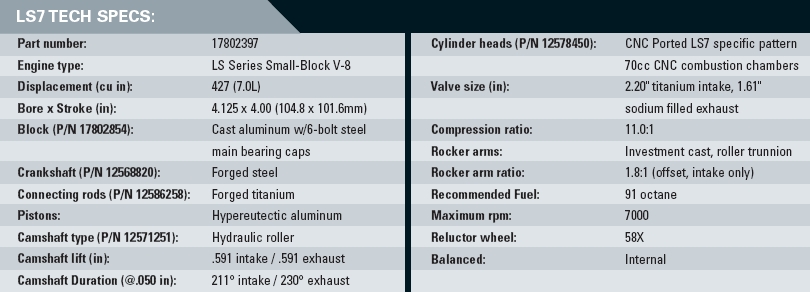

Here's the

GM specs on a stock LS7

As you can

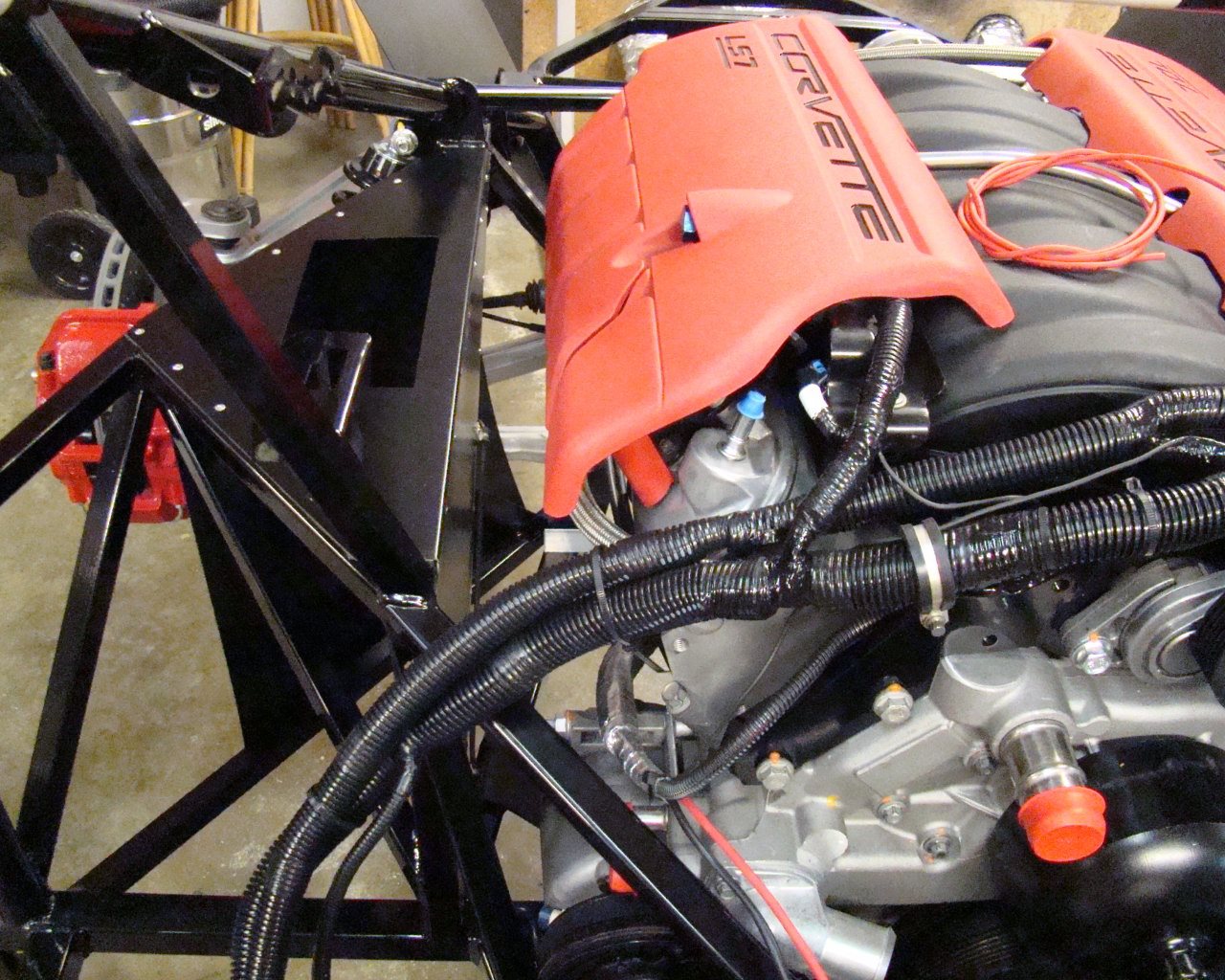

see the engine is pretty clean. I ended up doing a search on

the V.I.N. and called RPM Motors to get the Dyno info and a

character reference of the guy who had the car. Basically I

tracked it all on the net to figure out the history. Turns

out the engine was well taken care of and when I got it to the

house I verified again by checking cleanliness of the oil,

compression etc. All appears to be OK but I'm still a little

apprehensive about buying a built motor. The guy dropped

$8000 in motor work and added a 2 stage ACT clutch. It also

had Billy Boat headers and a Varam cold air intake still bolted to

it. Guess we'll see how it does. BTW, the GM dry sump tank

won't fit in the GTM so I'll be putting in a Peterson's Dry Sump

and filter tank from Schwartz

Performance.

The Package

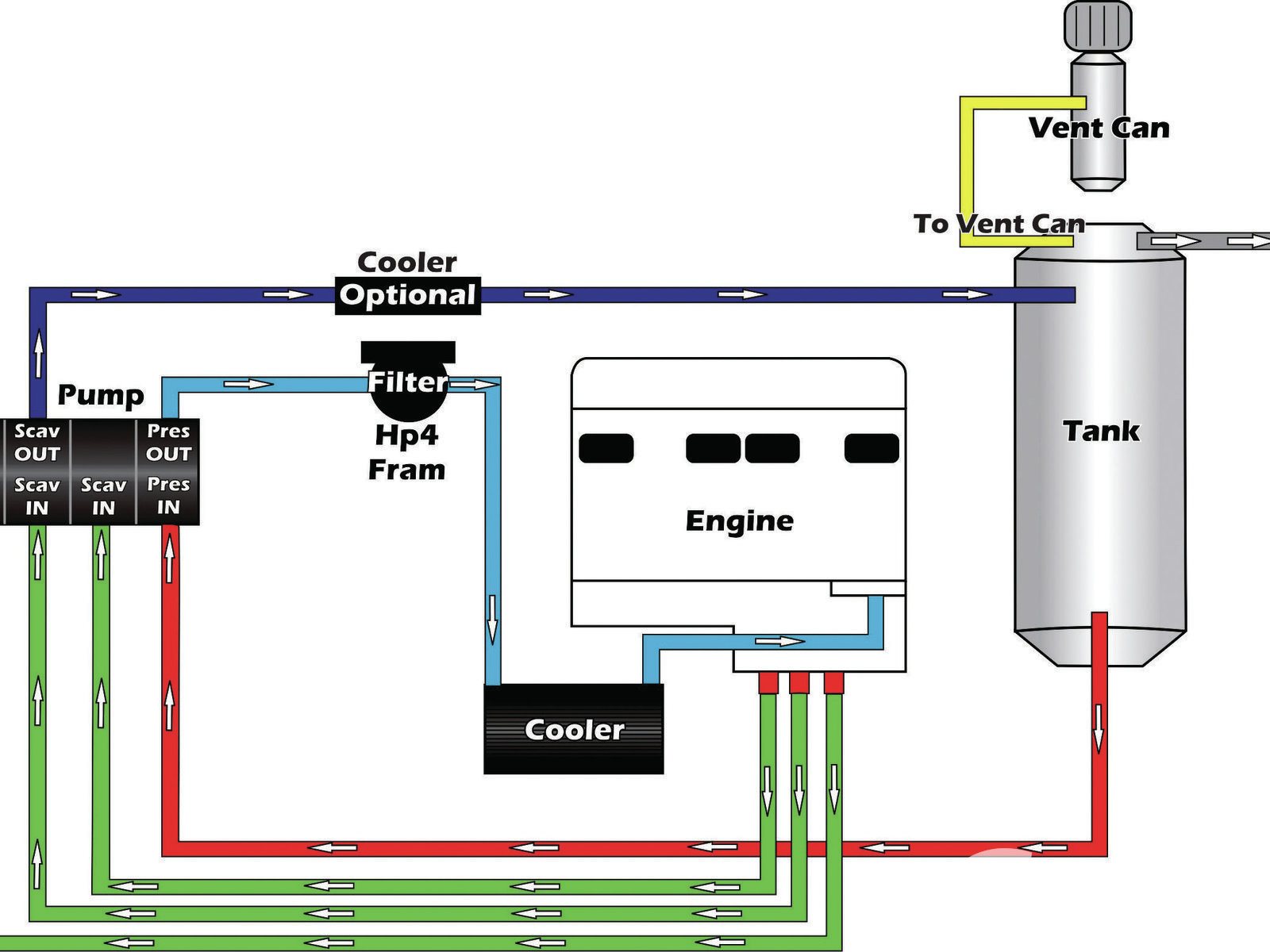

The GM dry sump system stores engine oil in a separate specially designed tank. Wikipedia has a good explanation of what this does... "

A dry sump offers many advantages,[1] the most obvious of which are increased oil capacity afforded by the remote reservoir and the capability to mount the engine lower in the car because of the thinner profile of the sump thereby lowering the overall center of gravity. The external reservoir can also be relocated to another part of the car to improve weight distribution. Increased oil capacity by using a larger external reservoir than would be practical in a wet sump system allows the oil to cool and release entrained gasses from ring blow by and the action of the crankshaft. Furthermore, dry sump designs are not susceptible to the oil movement problems that wet sump systems can suffer due to high cornering forces. If the oil in a wet sump is forced to one side in the oil pan the oil pump pickup tube can be temporarily uncovered leading to a loss of oil pressure. Because the scavenge pumps are typically mounted at the lowest point on the engine the oil flows into the pump suction by gravity rather than having to be lifted up into the suction of the pump like a wet sump does. Also the scavenge pumps can be of a different design that is more tolerant of entrained gasses than the typical pressure pump which can lose suction if too much air is mixed into the oil. Since the pressure pump is typically lower than the external oil tank it always has a positive pressure on its suction regardless of cornering forces. Another phenomenon that occurs in high-performance car engines is oil frothing up inside the crank-case due to the very high revs agitating the oil. Lastly, having the pumps external to the engine allows them to be maintained or replaced more easily.

Dry sumps are common on larger diesel engines such as those used for ship propulsion. Many racing cars, high performance sports cars, and aerobatic aircraft also utilize dry-sump equipped engines because they prevent oil-starvation at high g loads, and because their lower center of gravity positively affects performance.

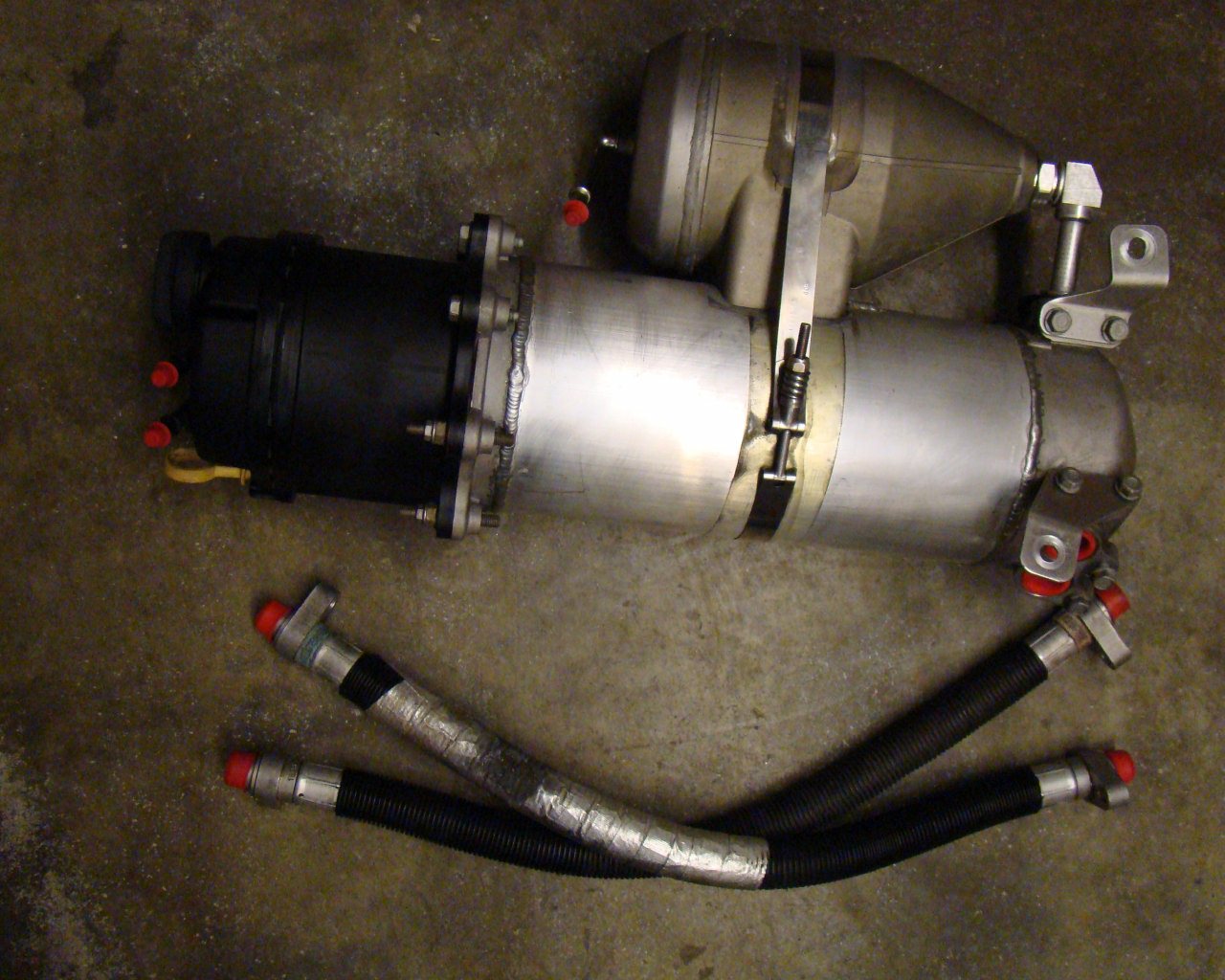

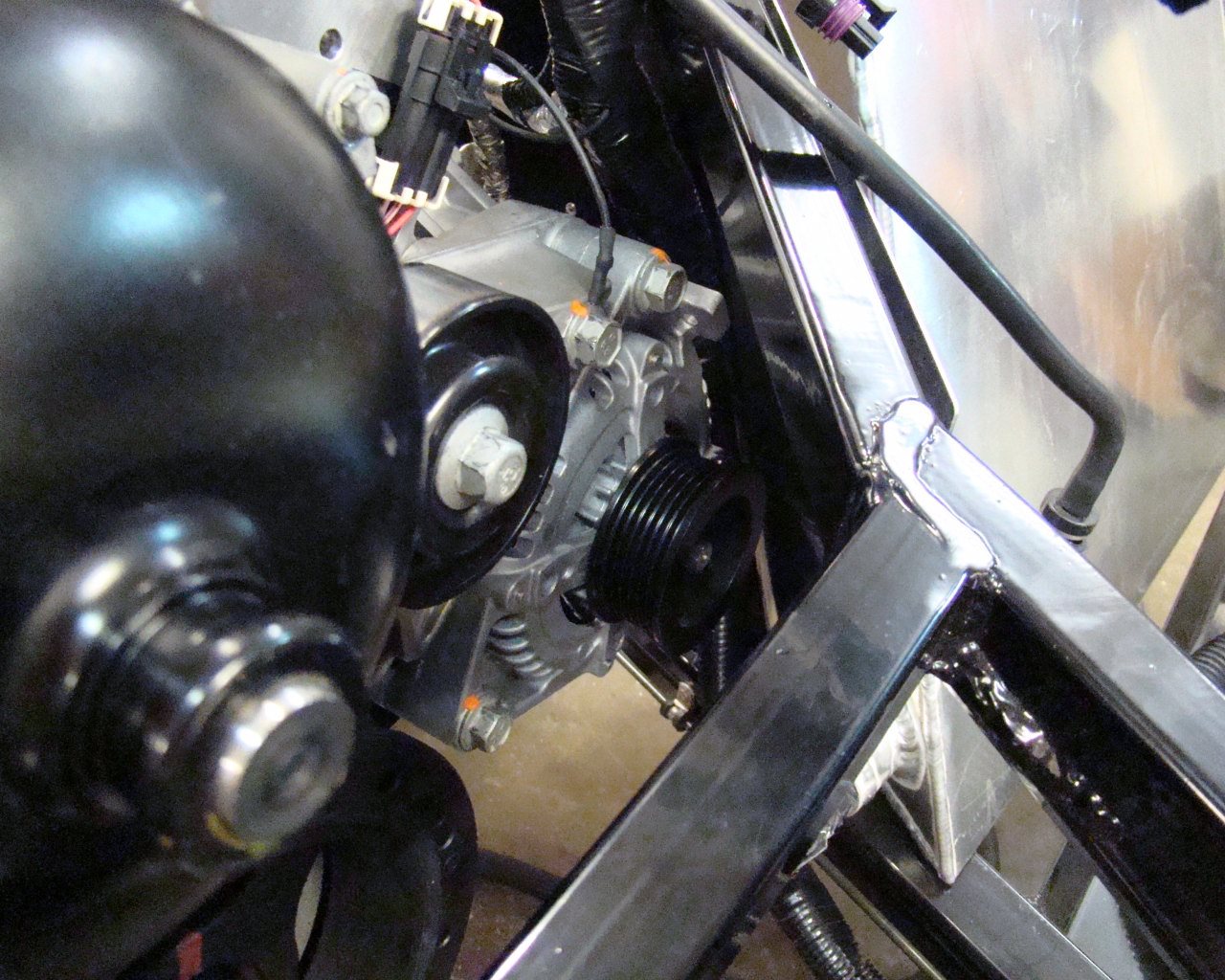

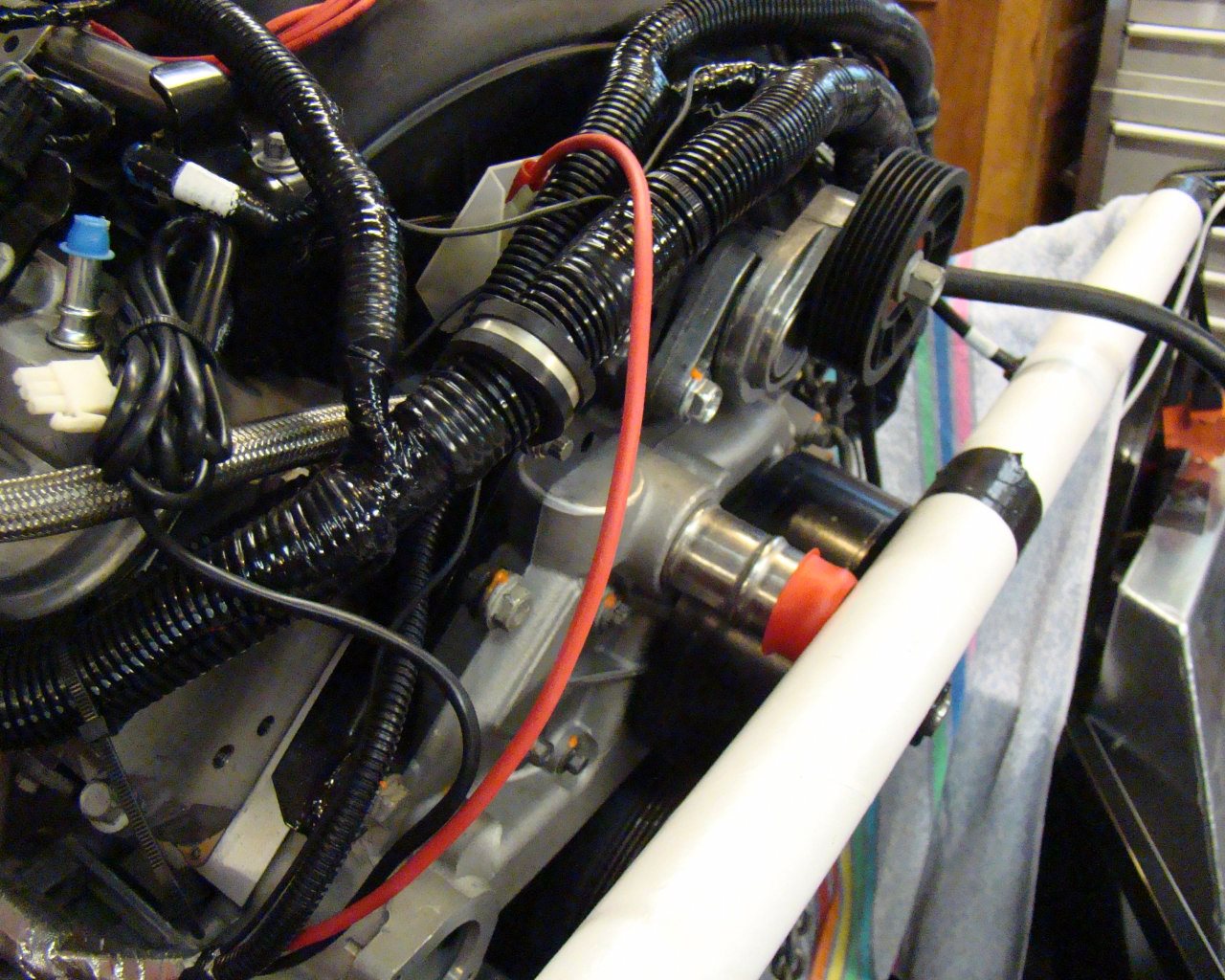

The above pictures show the Peterson tank and AN fittings used

to connect the system. Cost of the tanks and engine block

adapter runs about $650. You need to build up the lines using

a non-collapsing braided teflon hose or a steel spring cut to

length and inserted into the interior of the hoses. The

reason for this is that there's some vacuum in the system and

if you use a standard hose, it will collapse and prevent

flow.

ON TO THE BUILD..

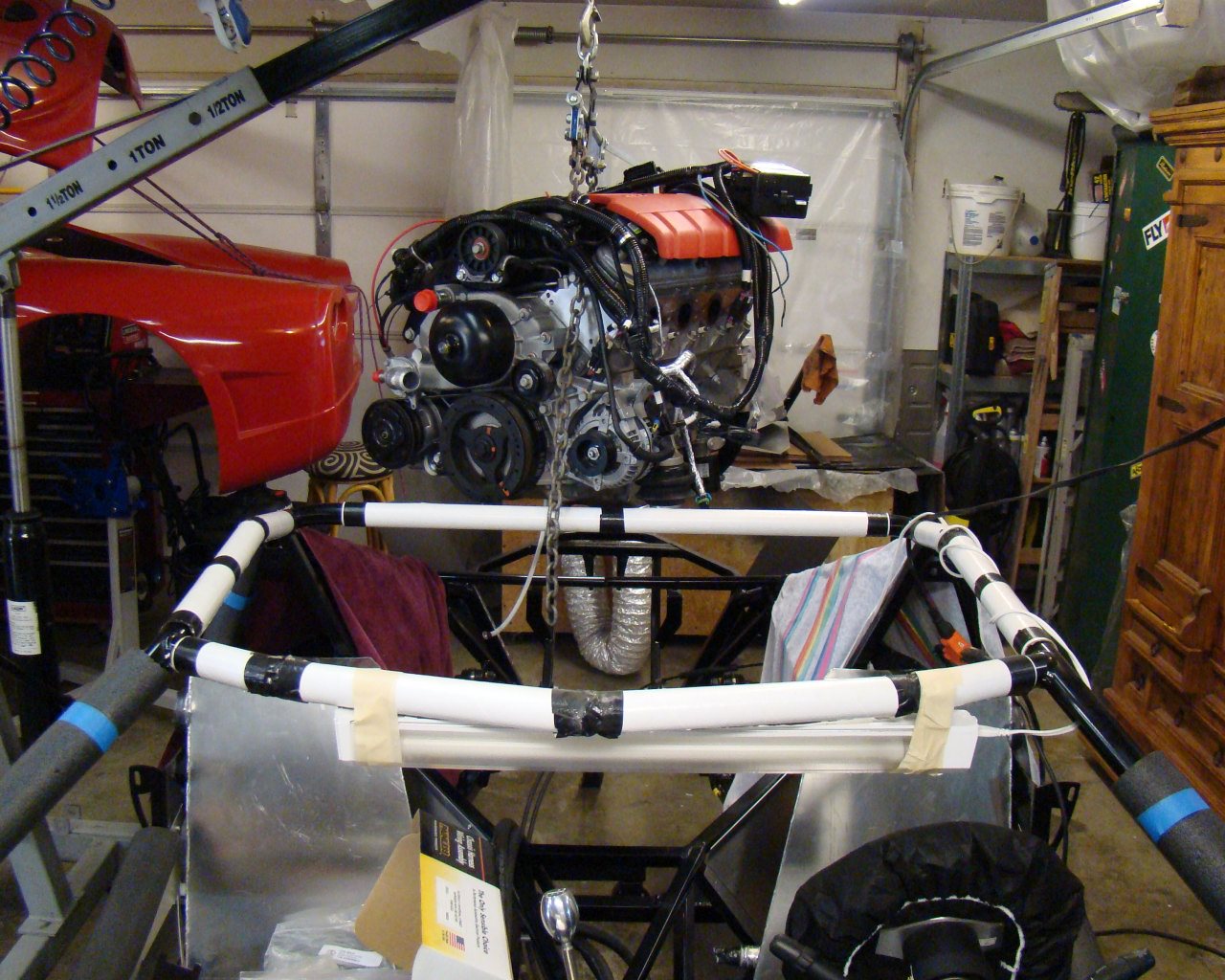

Installation:

Pre

Installation:

At this stage the engine is stock. I still need to reverse the intake and build the wiring harness to to adapt to the GTM. I'll likely go with the GM Performance Parts harness because it'll cut down on the guess work and time involved in splicing things together. Additionally, I'll need to get into the injector wiring for the Race Logic system which monitors injector pulses and tire rotaion at each tire and then selectively cuts out fuel delivery. This system is about the best you can get and provides some pretty smooth full pedal driving while preventing wheel spin.

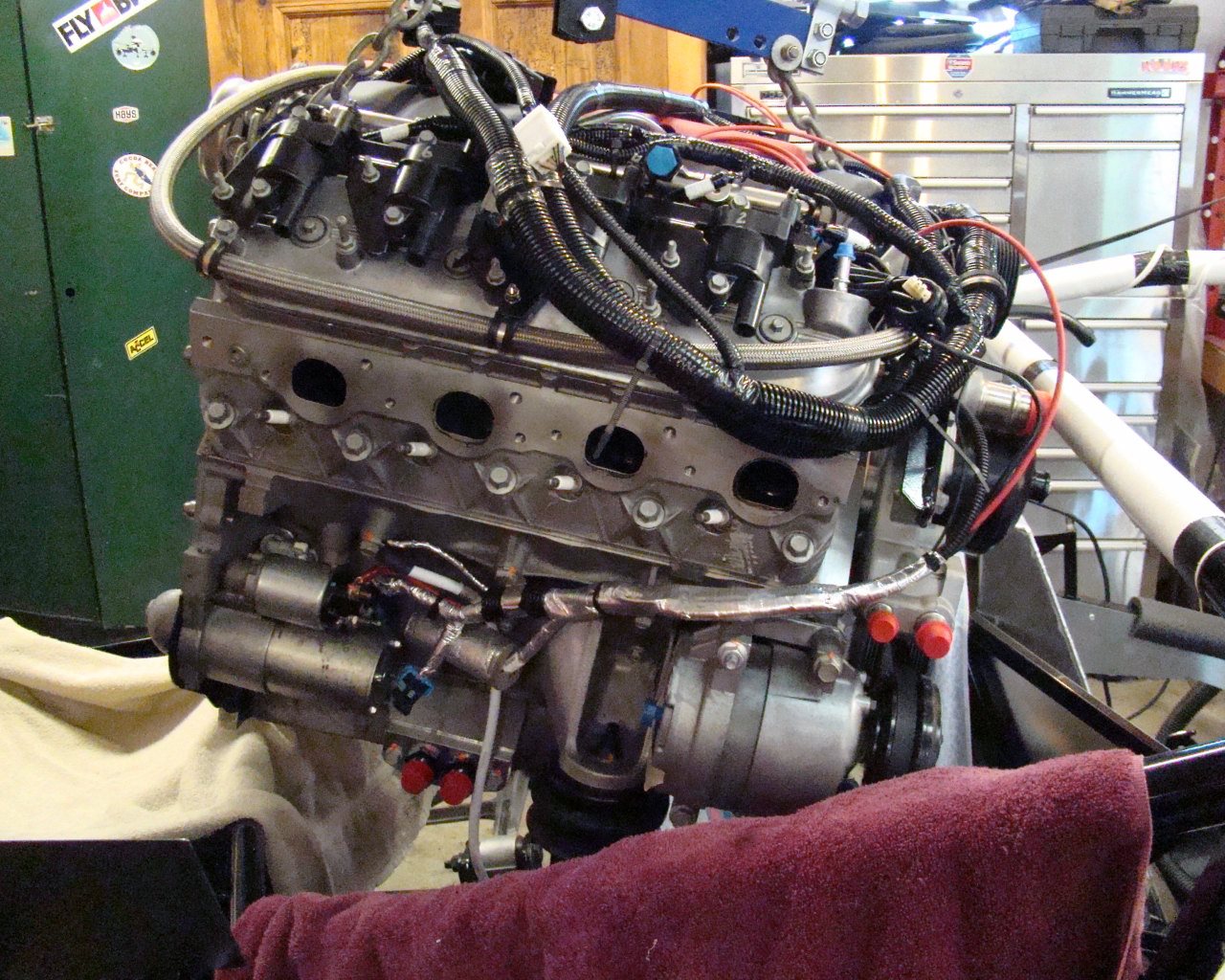

Pictures of

the new engine as delivered......