- INTERIOR SEATS AND UPHOLSTERY

- SURFBOARD PROJECT

- VIDEOS

- MENDEOLA TRANSAXLE INSTALL

- DOCUMENTS AND SCHEMATICS

- TECH & MODS

- CORVETTE FUEL RAIL COVER LOGO MOD

- CONTACT ME

- DONOR CORVETTE

- DELIVERY

- GTM BUILD SITES

- GTM PHOTOS

- LINKS

- HOME

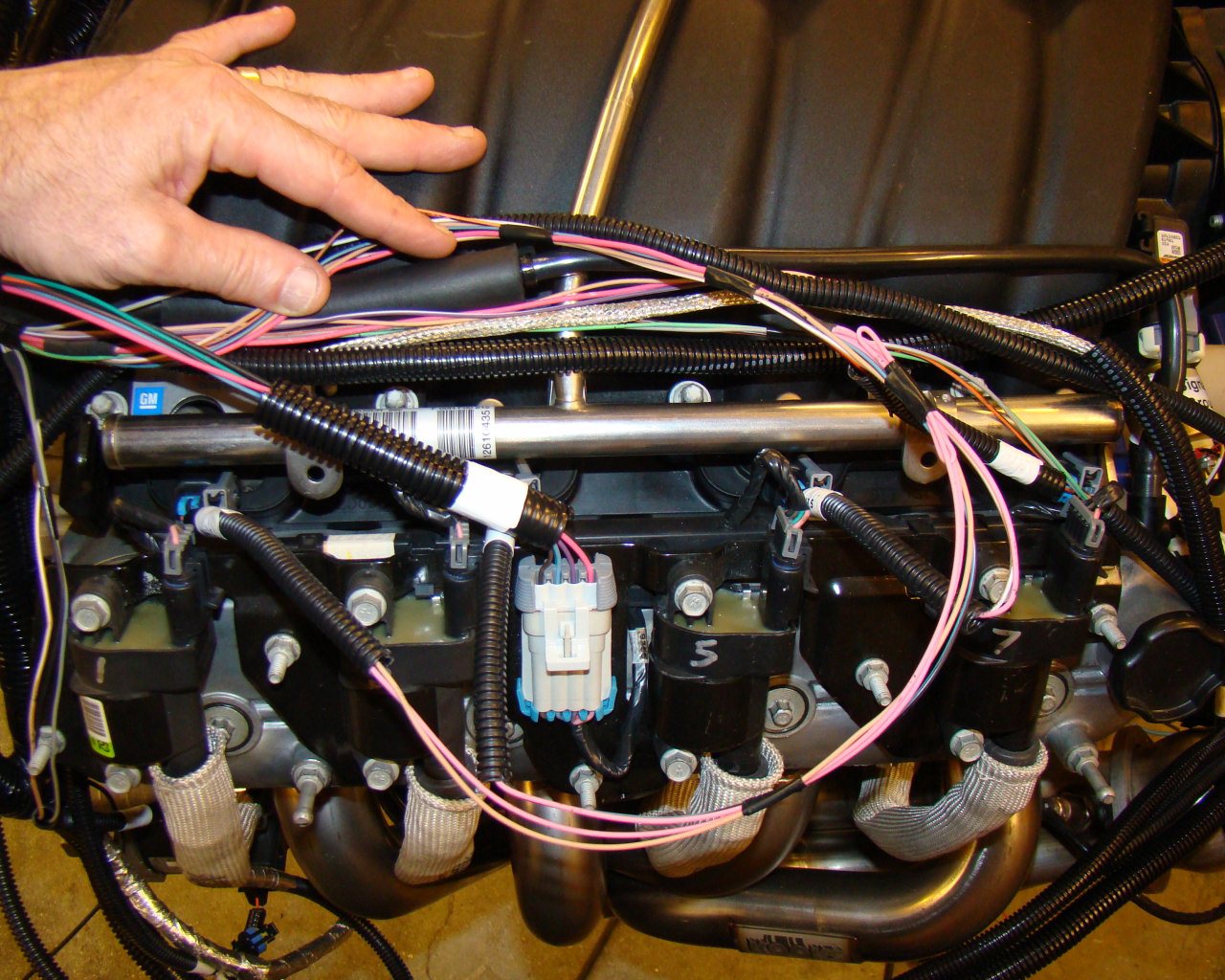

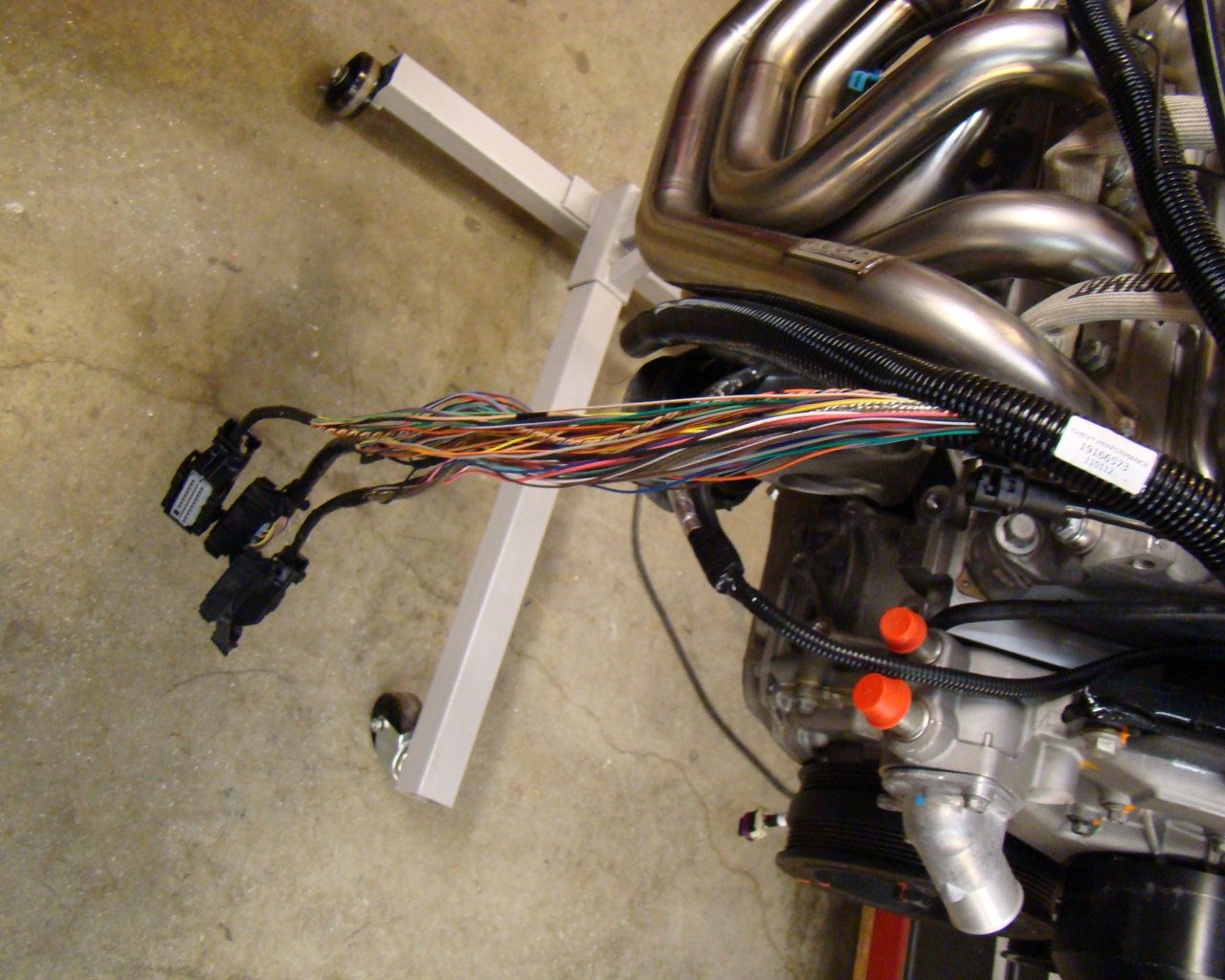

- ENGINE - LS7 BUILD AND INSTALL

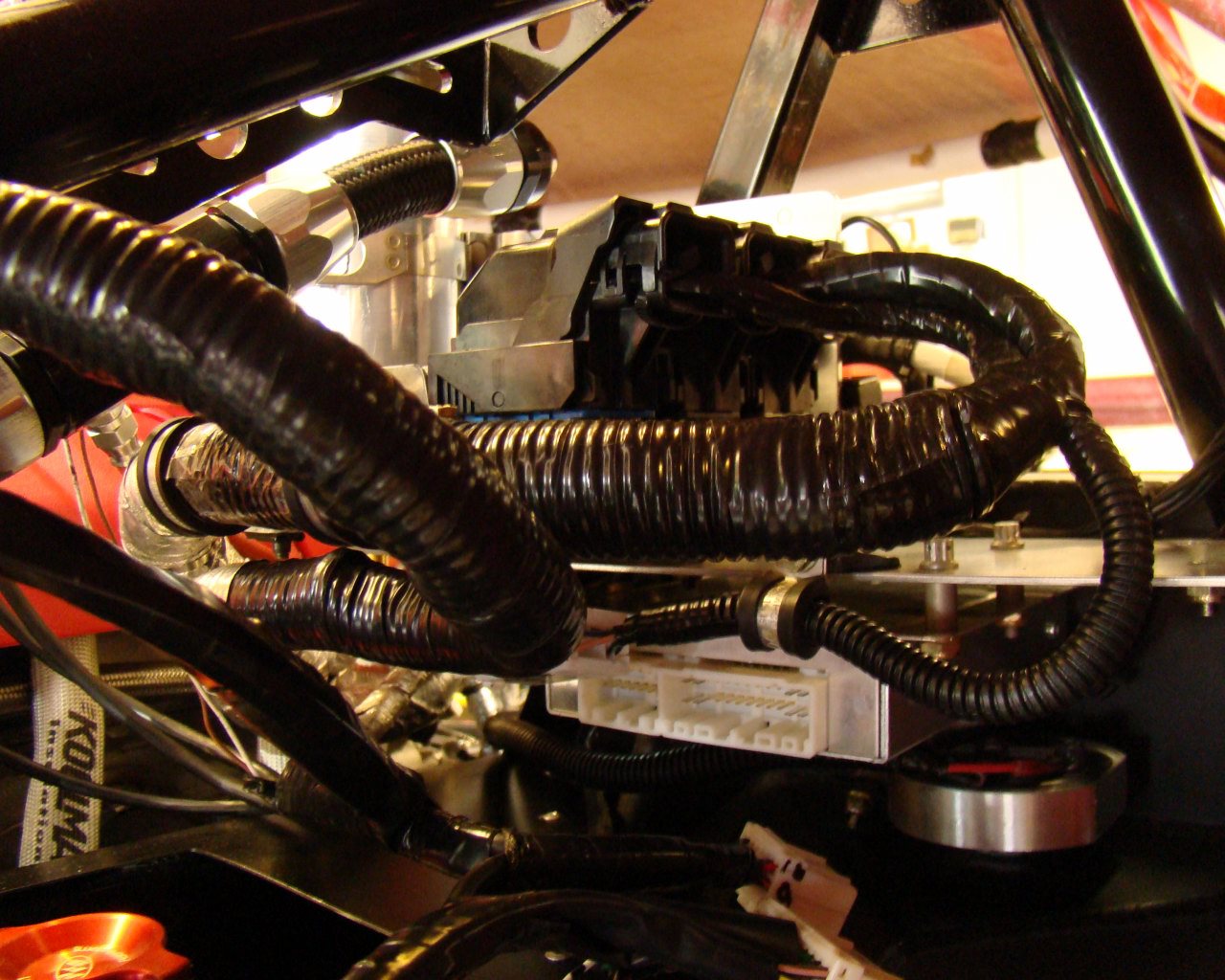

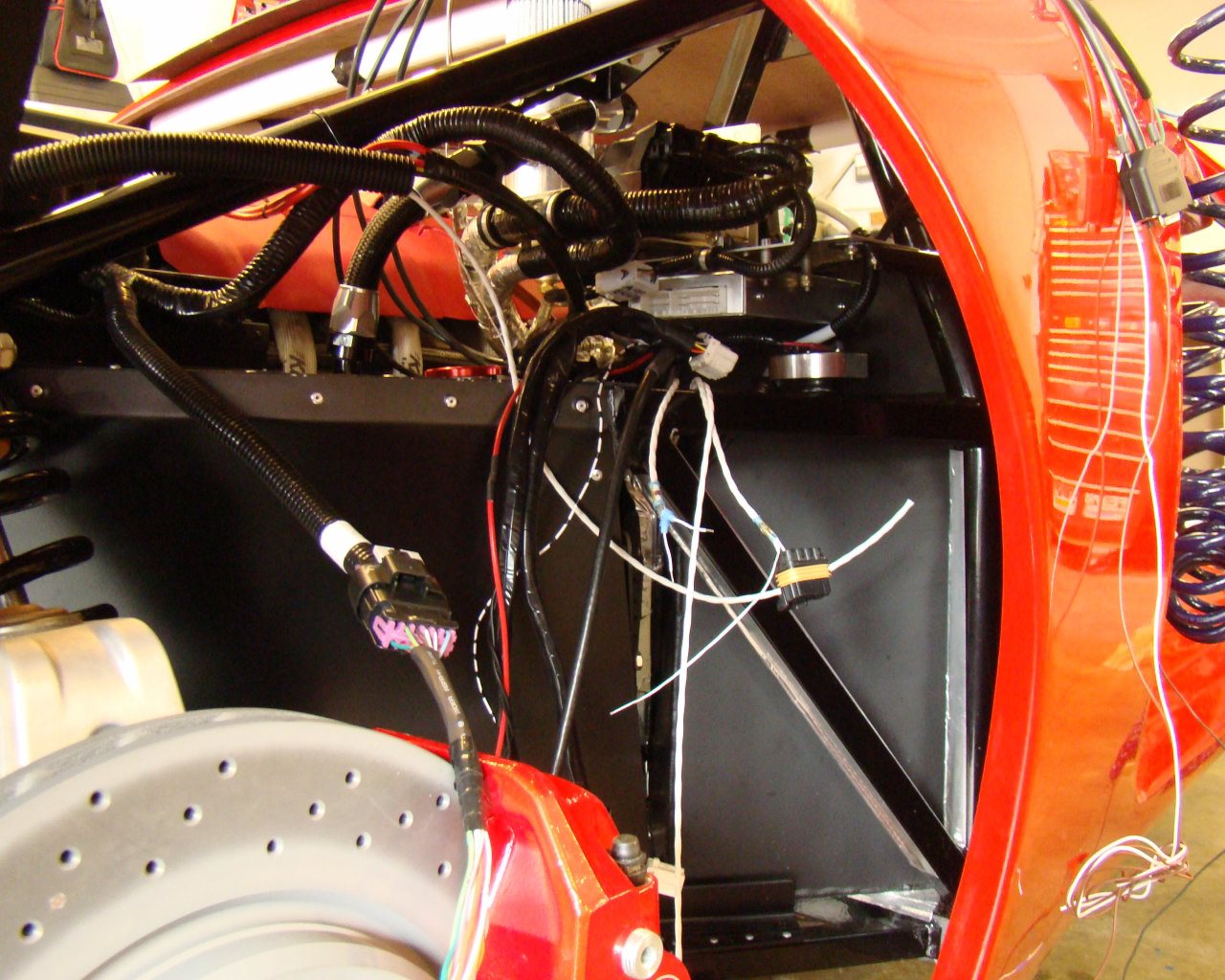

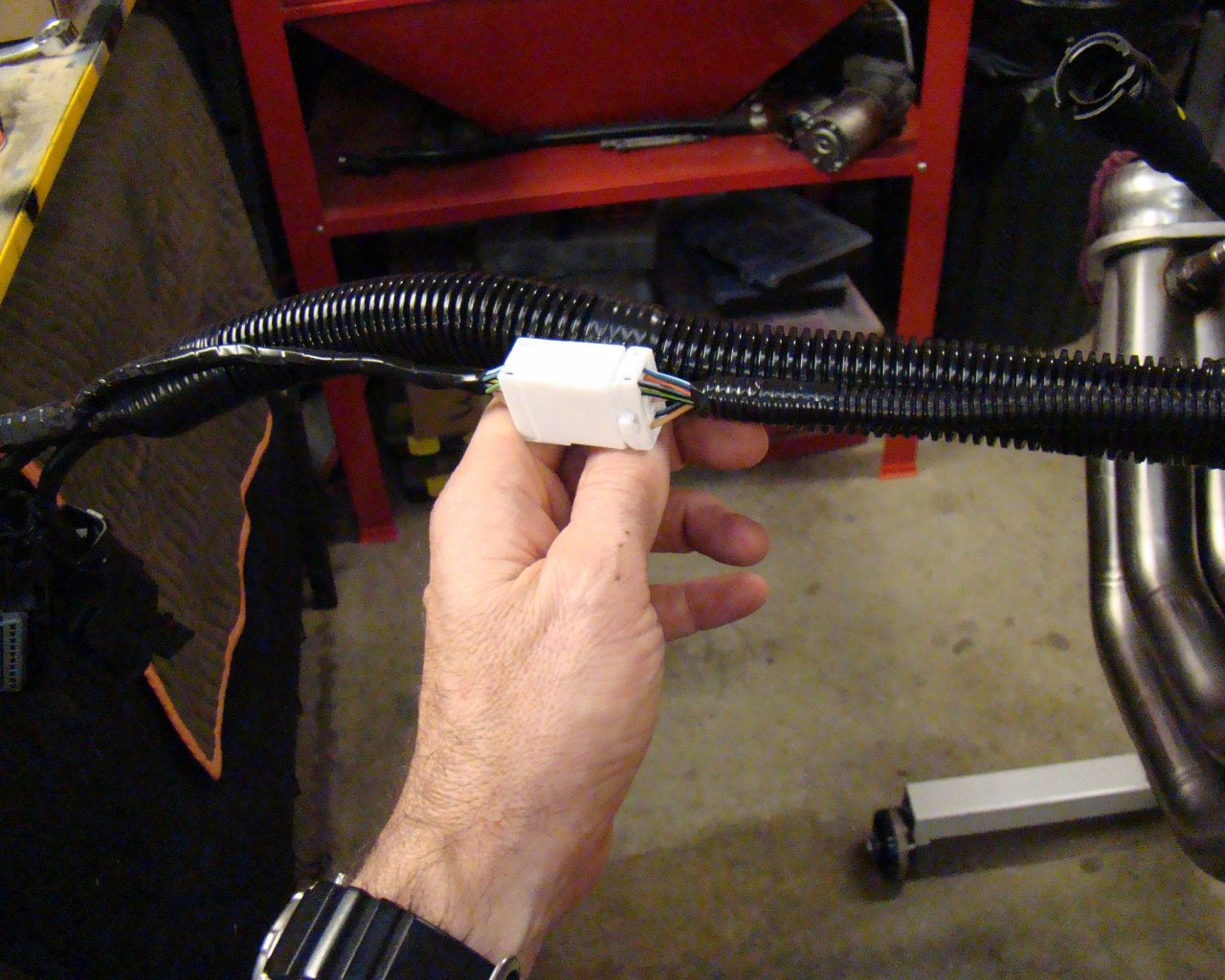

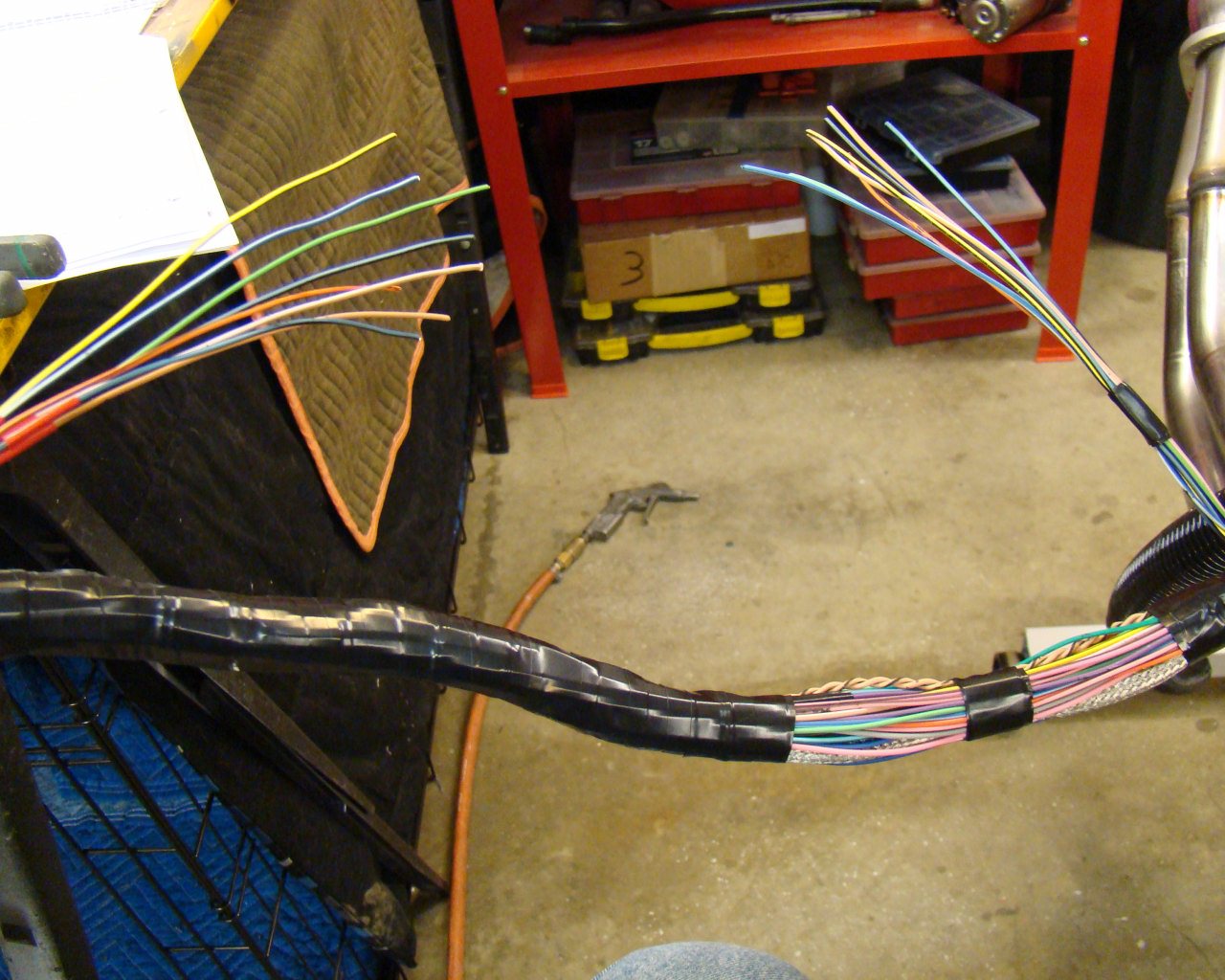

- CHASSIS AND ELECTRICAL BUILDUP

- ASSEMBLY CONTENTS

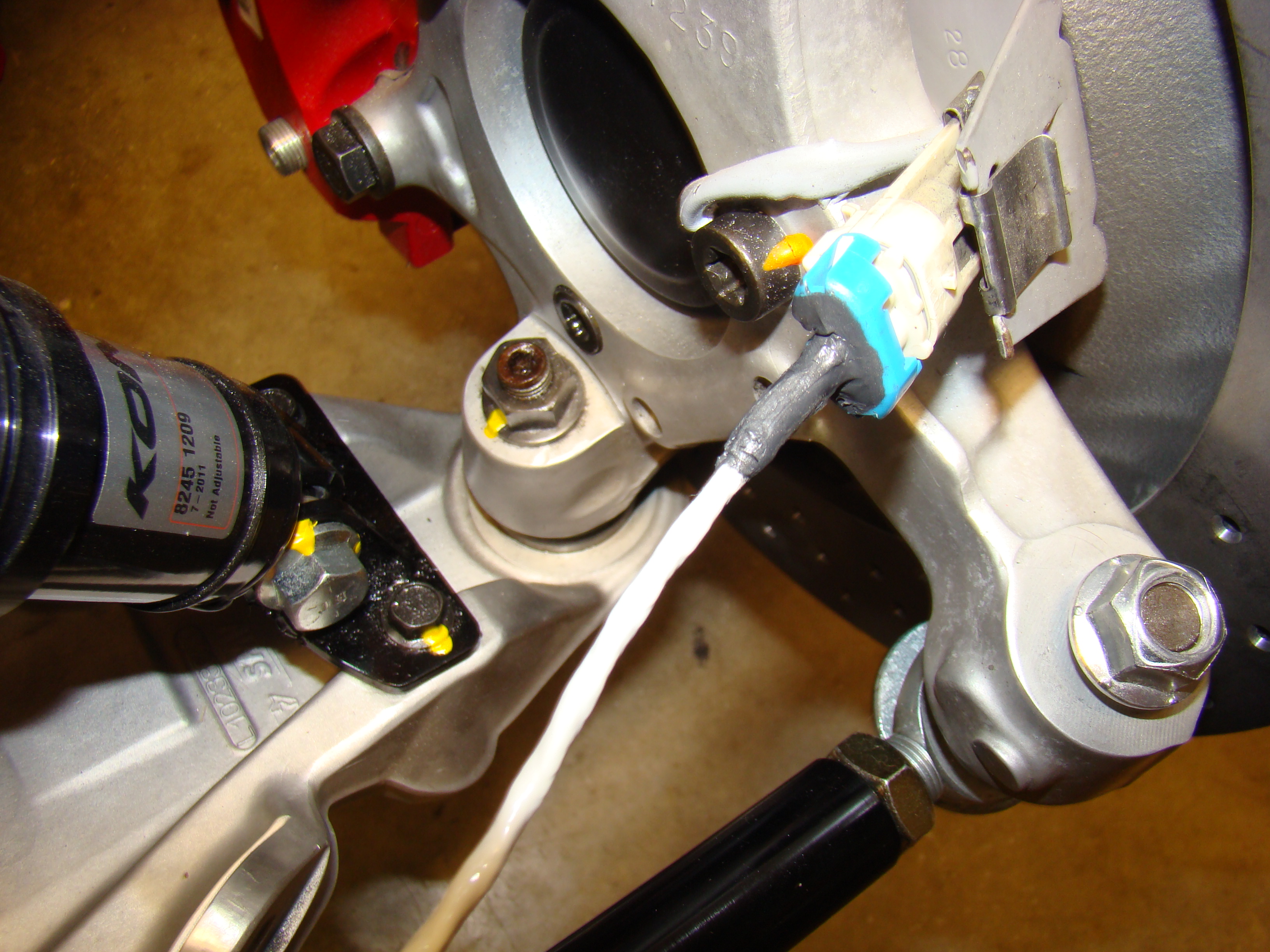

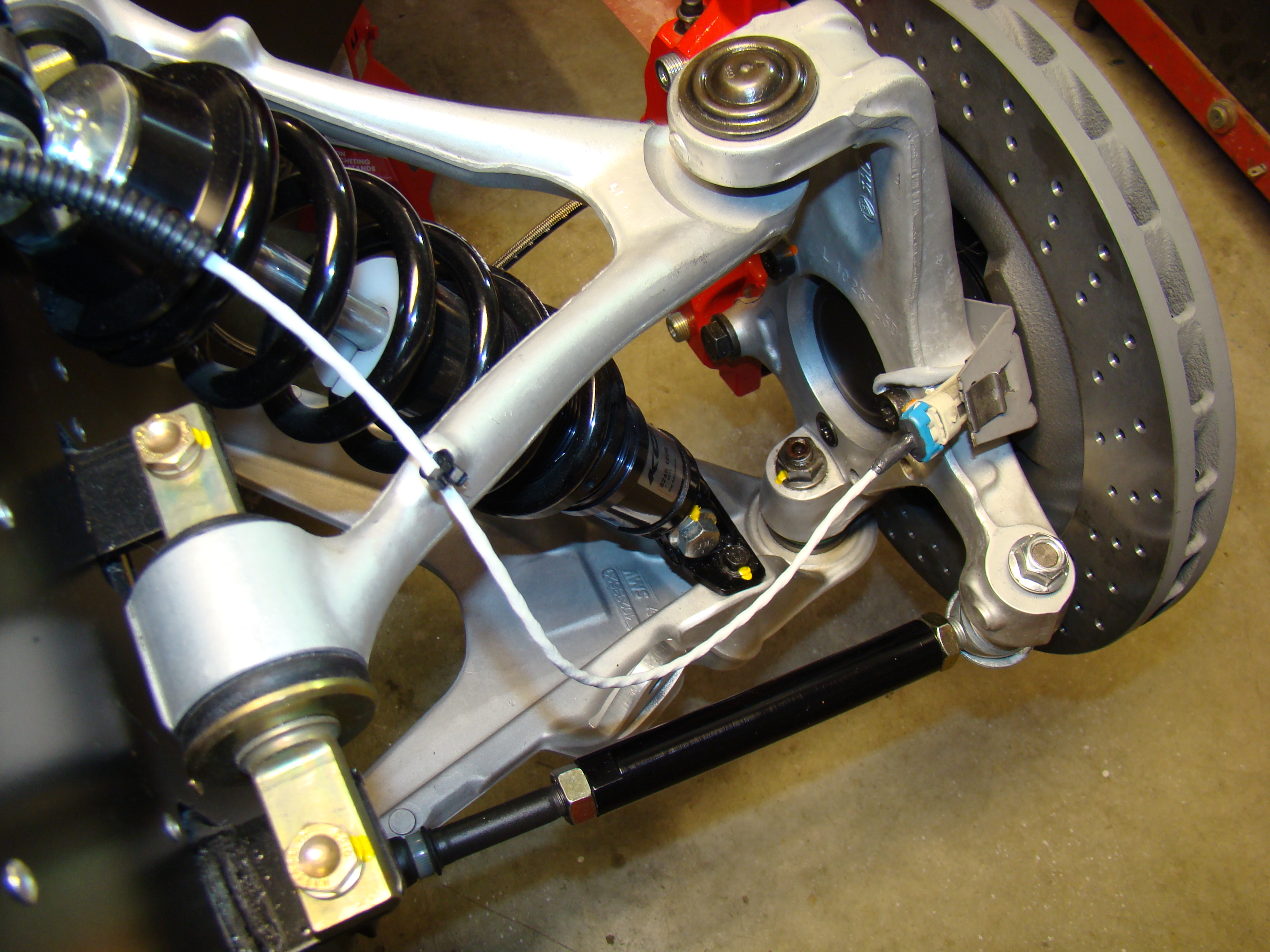

- SUSPENSION

- BRAKES

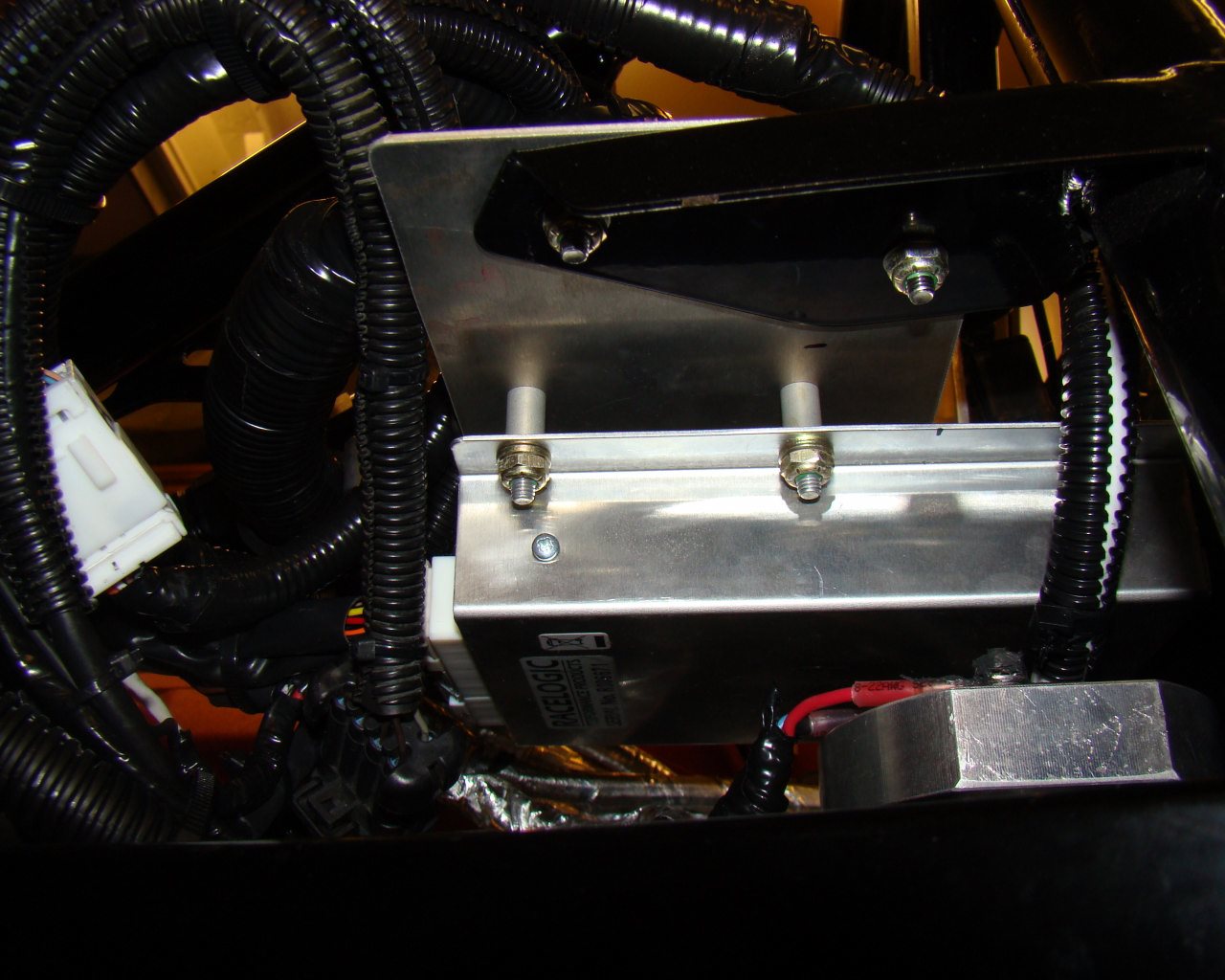

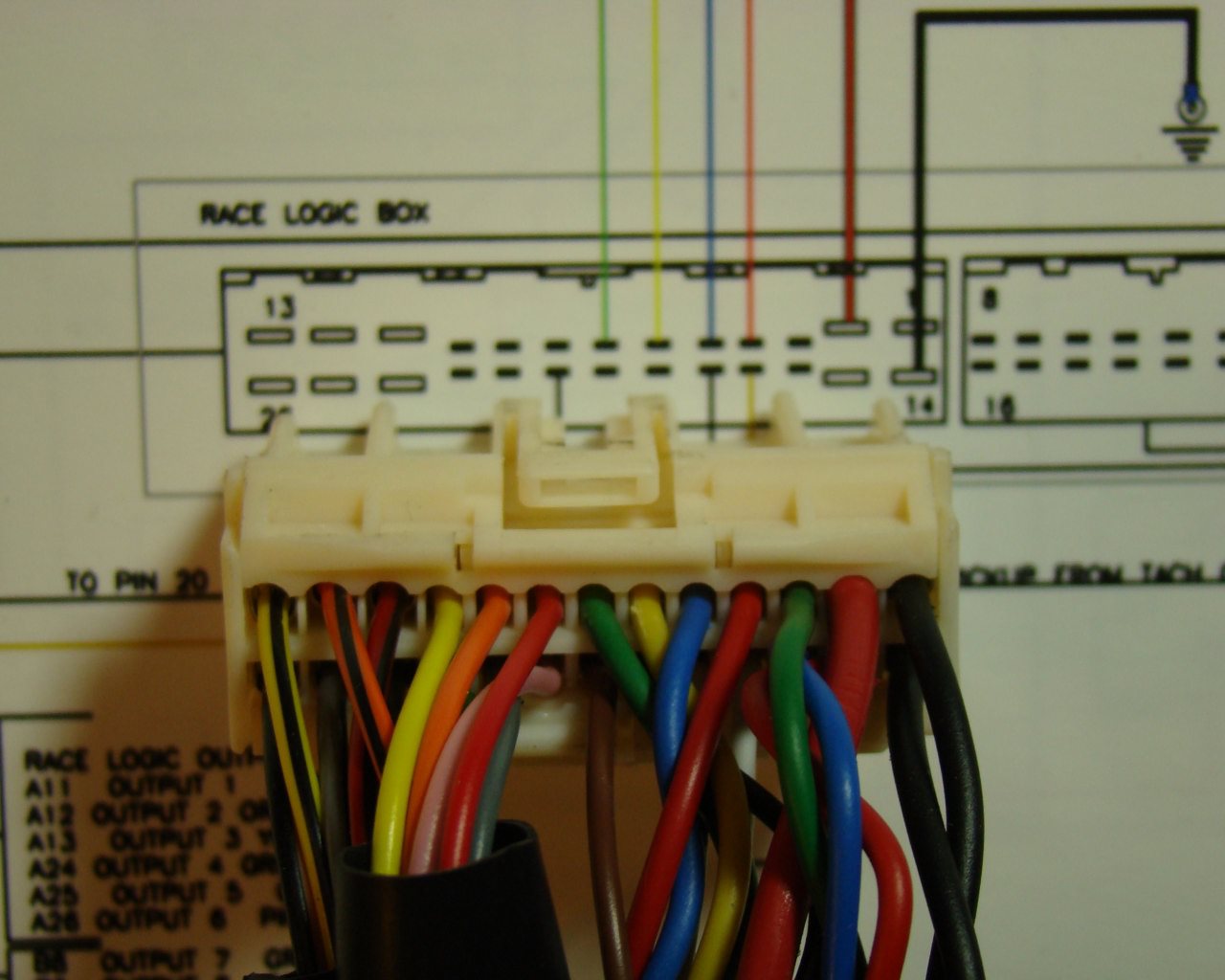

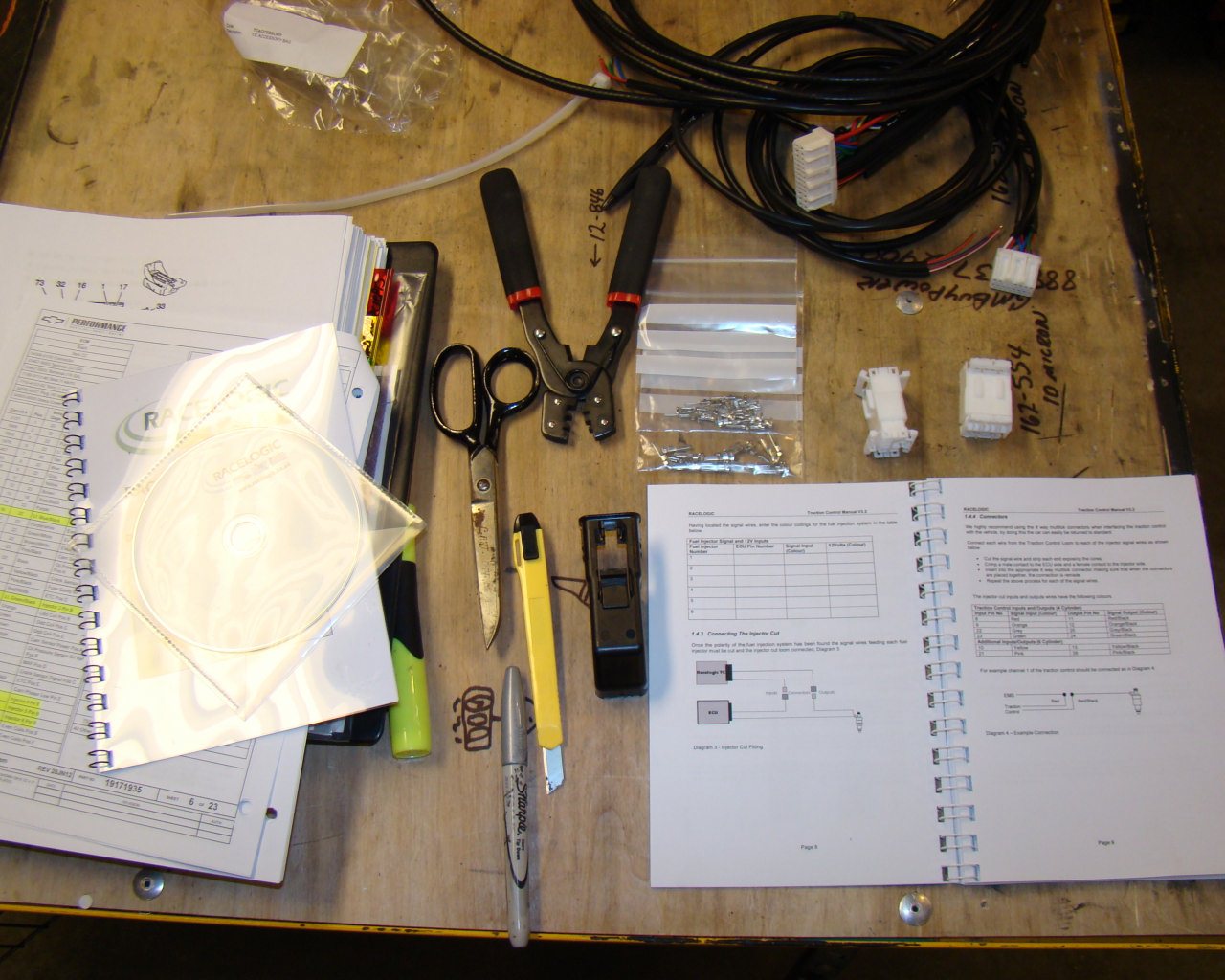

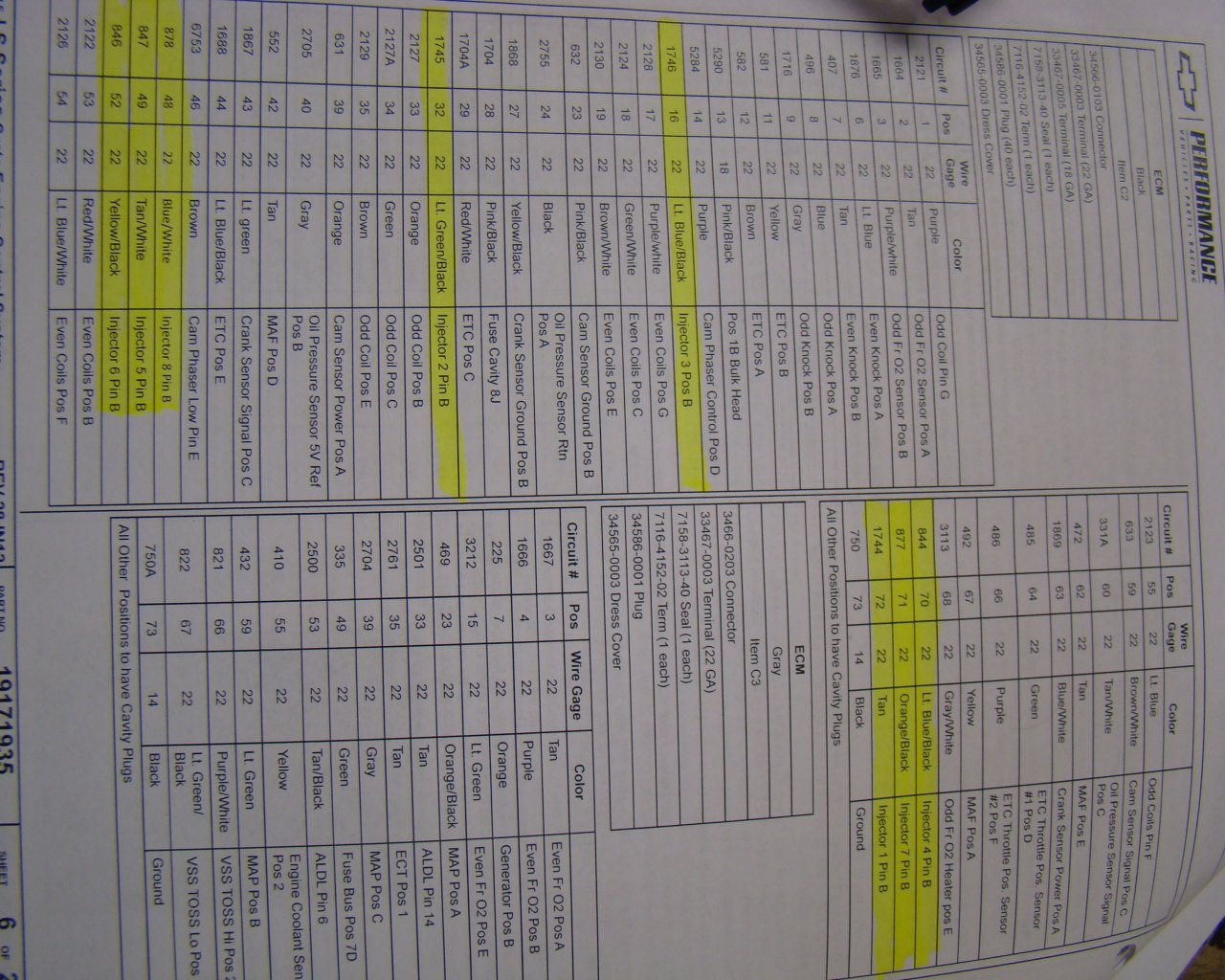

- RACE LOGIC TRACTION CONTROL

- ALUMINUM PANELS

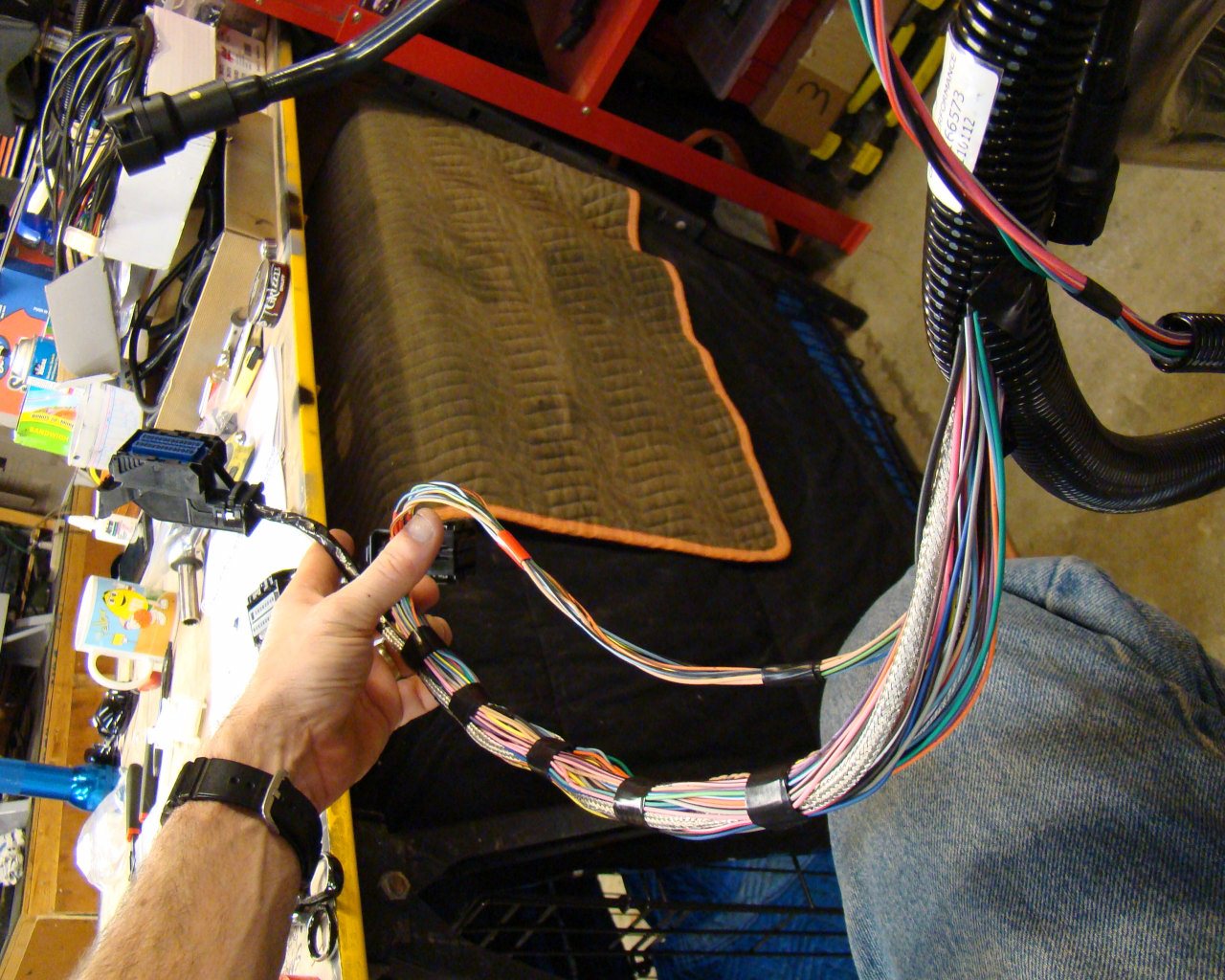

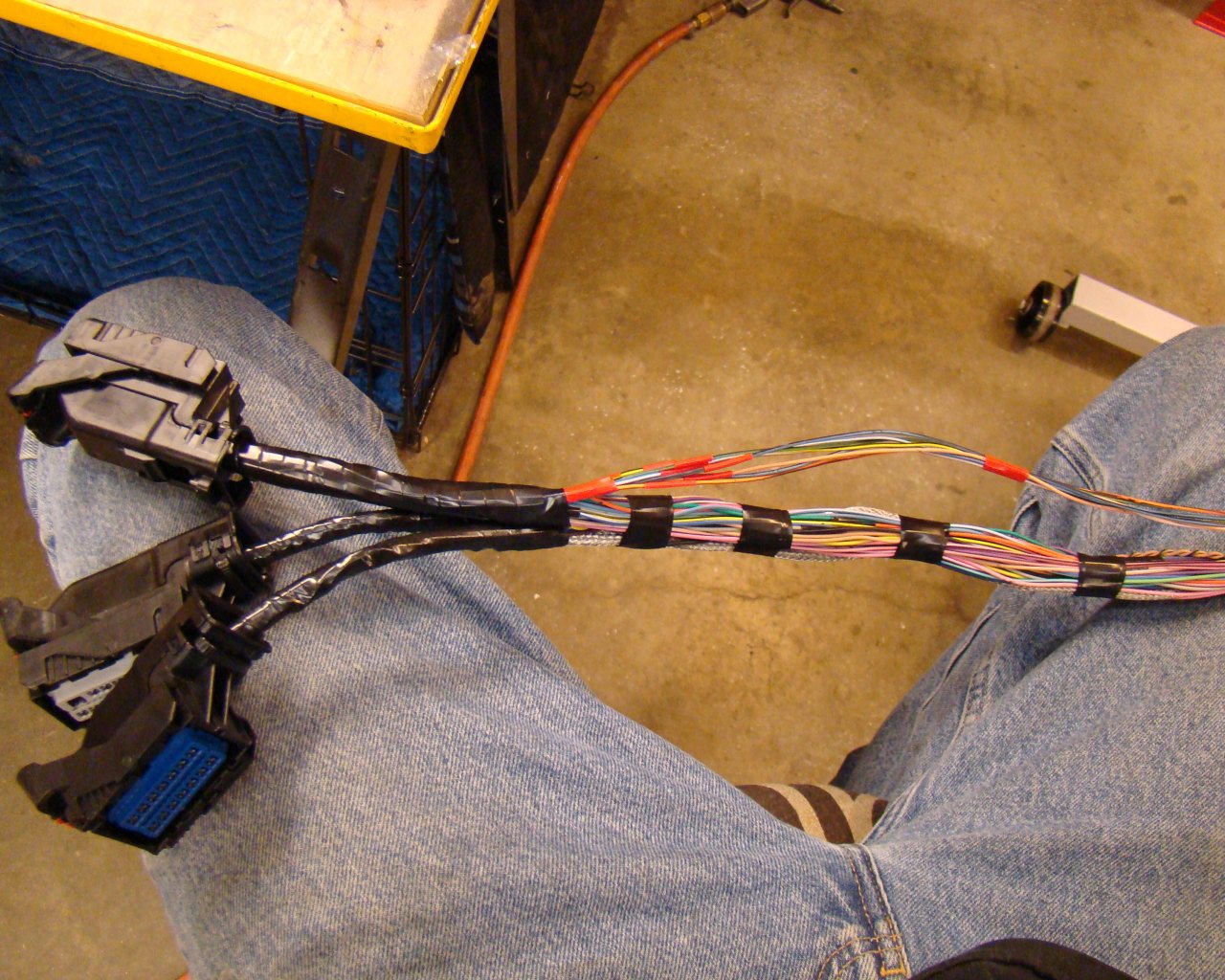

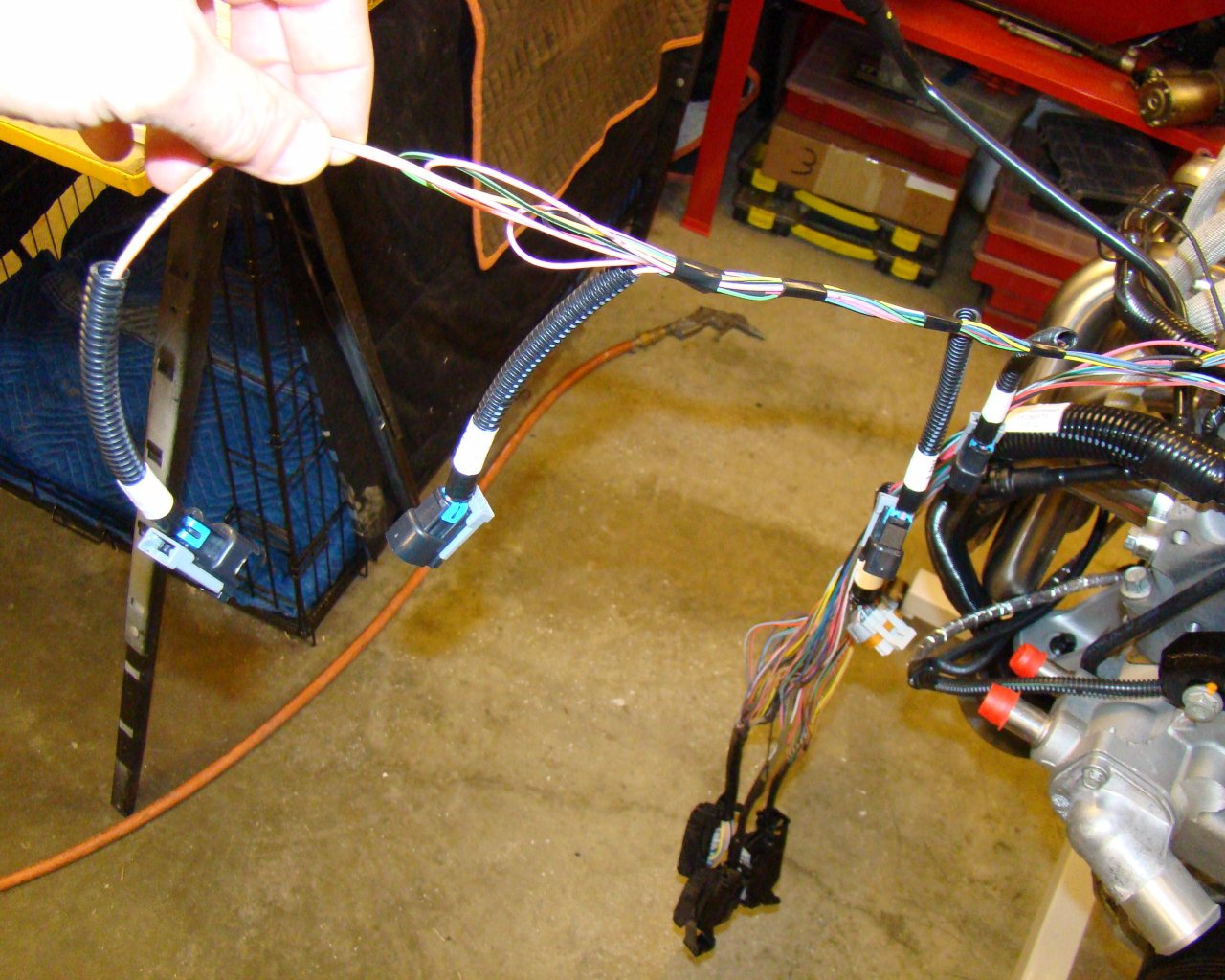

- ELECTRIC

- A/C + ENVIRONMENTAL

- STEERING

- ALUMINUM FOOT BOX PANELS

- FLOOR AND UNDERCARRIAGE

- TUNNEL ACCESS PANELS

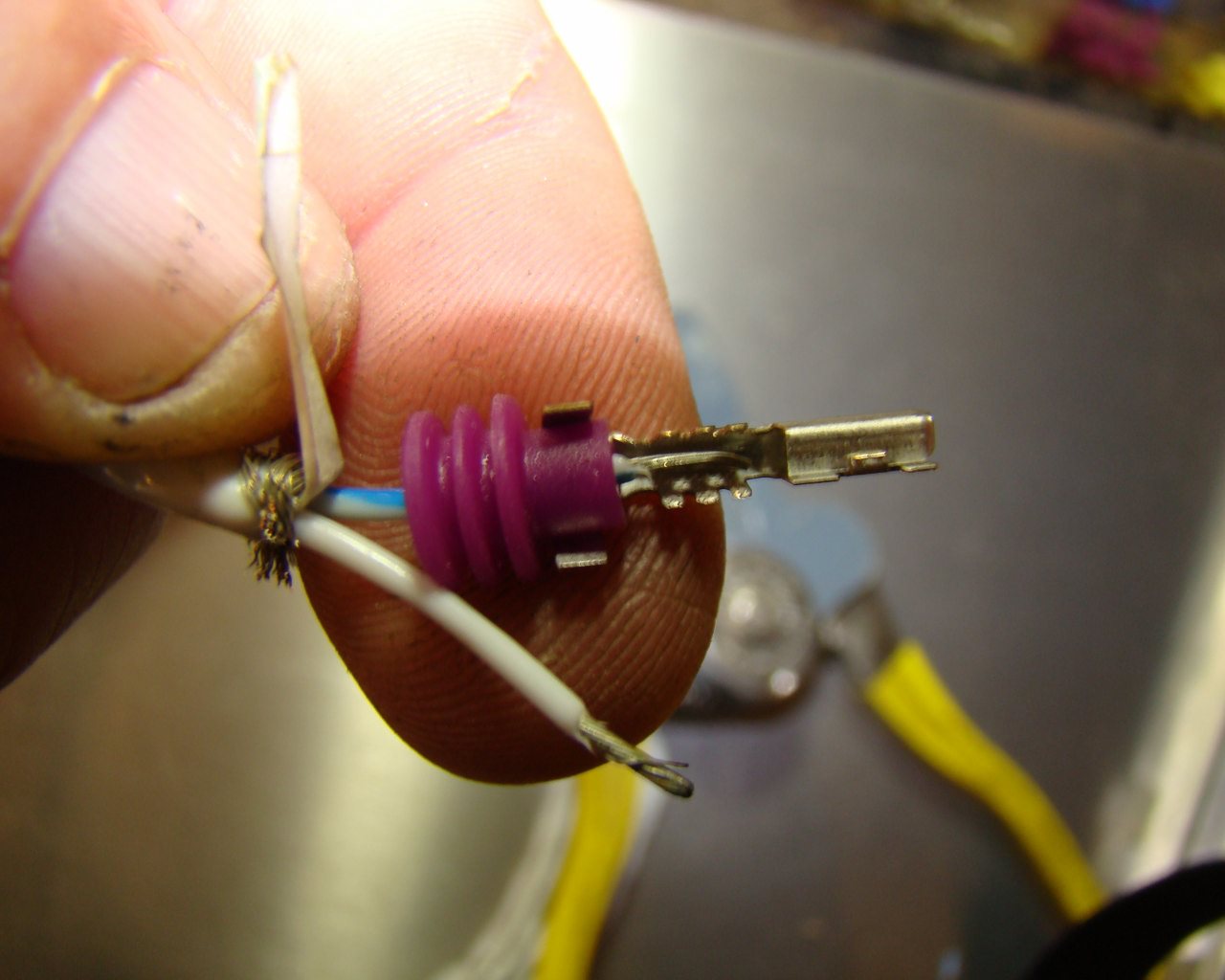

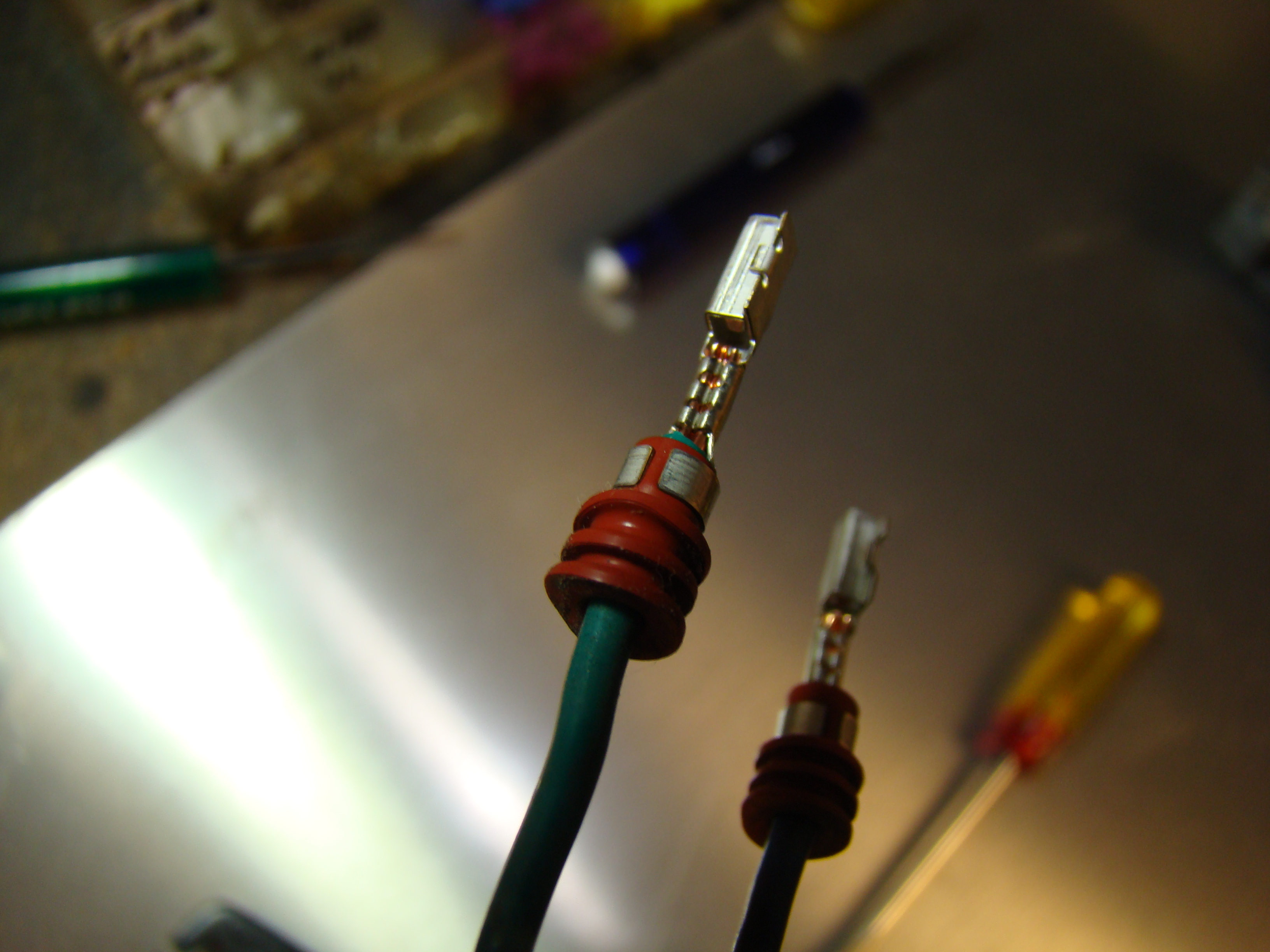

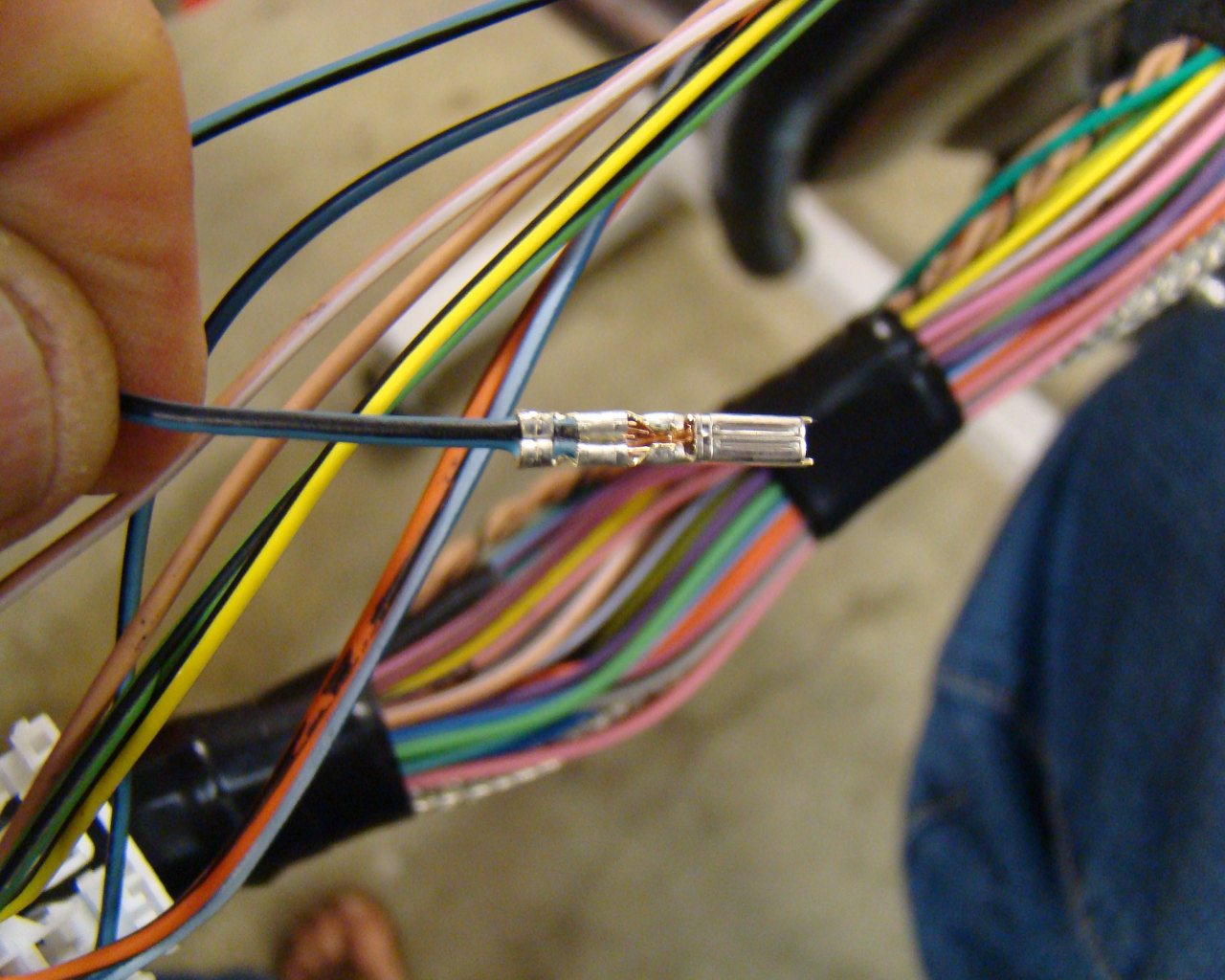

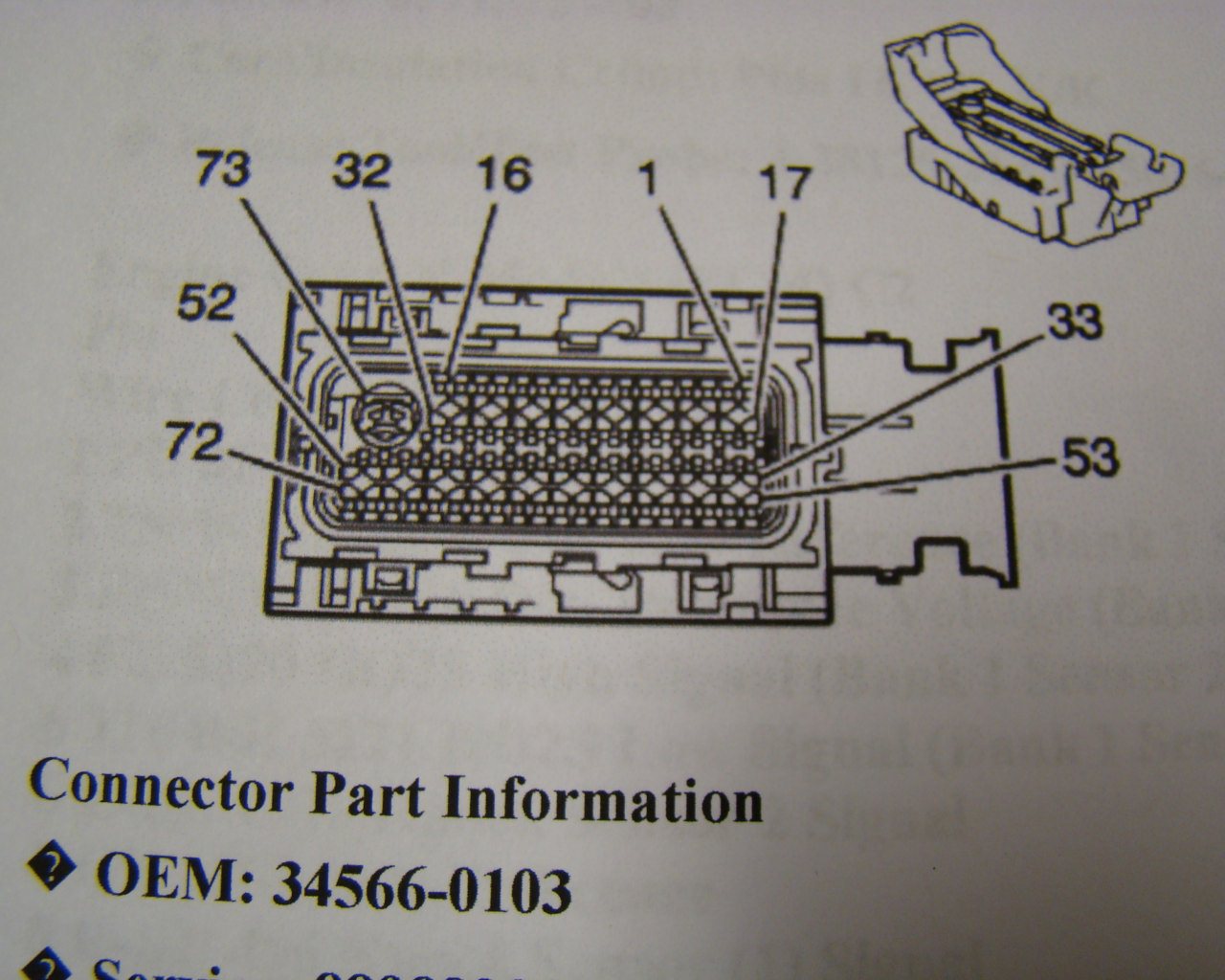

- GM/DELPHI TERMINAL CRIMP

- PEDALS AND SWITCHES

- WHEELS AND BACKSPACING

- CLUTCH

- SHIFTER

- E-BRAKE

- VRSW WING AND WING MOUNT

- LIGHTS

- EMERGENCY BRAKE SERVO

- ALIGNMENT

- BODY AND DOORS

RACELOGIC SYSTEM DESCRIPTION: The system works by monitoring the speed of all four wheels using the ABS system or specially fitted sensors. When wheel spin is detected the engine power is reduced, by cutting a single injector pulse, until grip is resumed. This occurs in a thousandth of a second, and appears to the driver as a slight misfire with no loss in acceleration. Maximum acceleration is achieved by limiting the slip between the tyre and the road. The point at which a tyre is just beginning to slip against the road gives the maximum coefficient of friction value.

The maximum coefficient of friction (µ) occurs at a slip between tyre and road of 10% when dry, and around 5% when wet. Many factors affect the ideal level of slip, wet / dry conditions, speed of the vehicle, lateral g-force (cornering), tyre compound, tyre pressures etc. Ideally the driver should be able to dial in a base level of slip that takes into account weather and tyres, and the system should adjust automatically for speed of the vehicle and lateral g-force. When cornering, the system will reduce the amount of slip available, to prevent lateral slip from occurring, and vary this amount depending on the speed of the vehicle. At high speed, low grip situations, this slip should be around 1-2% to maintain forward momentum, and at low speed high grip situations, this can be much higher.

CUTTING A SINGLE INJECTOR PULSE

The idea of cutting fuel to an engine sets alarm bells ringing in engine builders, as they all know that running a lean combustion mode will elevate in-cylinder temperatures very rapidly. The denser the air/fuel charge, the more heat the lean burn can generate. Therefore it is vital that a fuel cut system will not cause a lean burn.

Racelogic Traction Control prevents lean burn by removing 100% of the pulsed fuel delivery – essentially the affected cylinder takes a gulp of fresh air; the in-cylinder temperature remains virtually unaffected. Prolonged fuel cut on one particular cylinder would cause scavenging of the petrol lining the inlet tracts, and when the next full fuel pulse arrived, it would be partially reduced in quantity by the re-wetting of these tracts. RL Traction Control rotates cylinder cutting to prevent this situation from occurring.